作者简介:许睿轩(1995-),男,硕士研究生,从事含能材料改性技术研究。E-mail:triplexu@163.com 通信作者:安崇伟(1980-),男,教授,从事新型传爆药技术研究。E-mail:anchongwei@yeah.net

(1.中北大学 环境与安全工程学院,山西 太原 030051; 2.山西省超细粉体工程技术研究中心,山西 太原 030051)

(1. School of Environment and Safety Engineering, North University of China,Taiyuan 030051, China;2.Shanxi Engineering Technology Research Center for Ultrafine Powder,Taiyuan 030051, China)

applied chemistry; 1,1-diamino-2,2-dinitroethylene; FOX-7; jet crystallization method; thermal performance analysis; mechanical sensitivity

DOI: 10.14077/j.issn.1007-7812.202005005

备注

作者简介:许睿轩(1995-),男,硕士研究生,从事含能材料改性技术研究。E-mail:triplexu@163.com 通信作者:安崇伟(1980-),男,教授,从事新型传爆药技术研究。E-mail:anchongwei@yeah.net

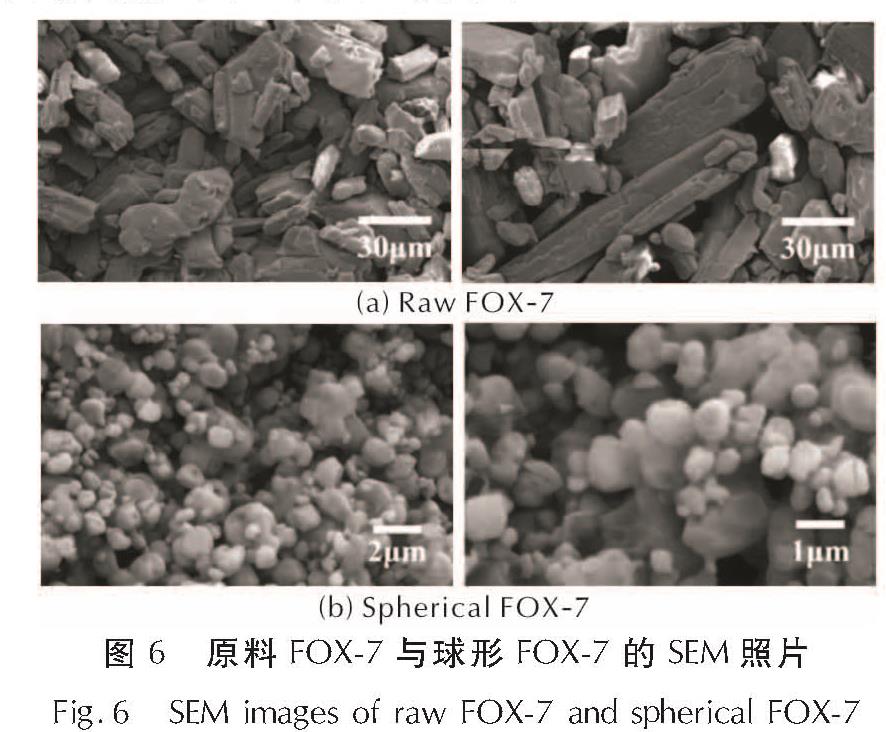

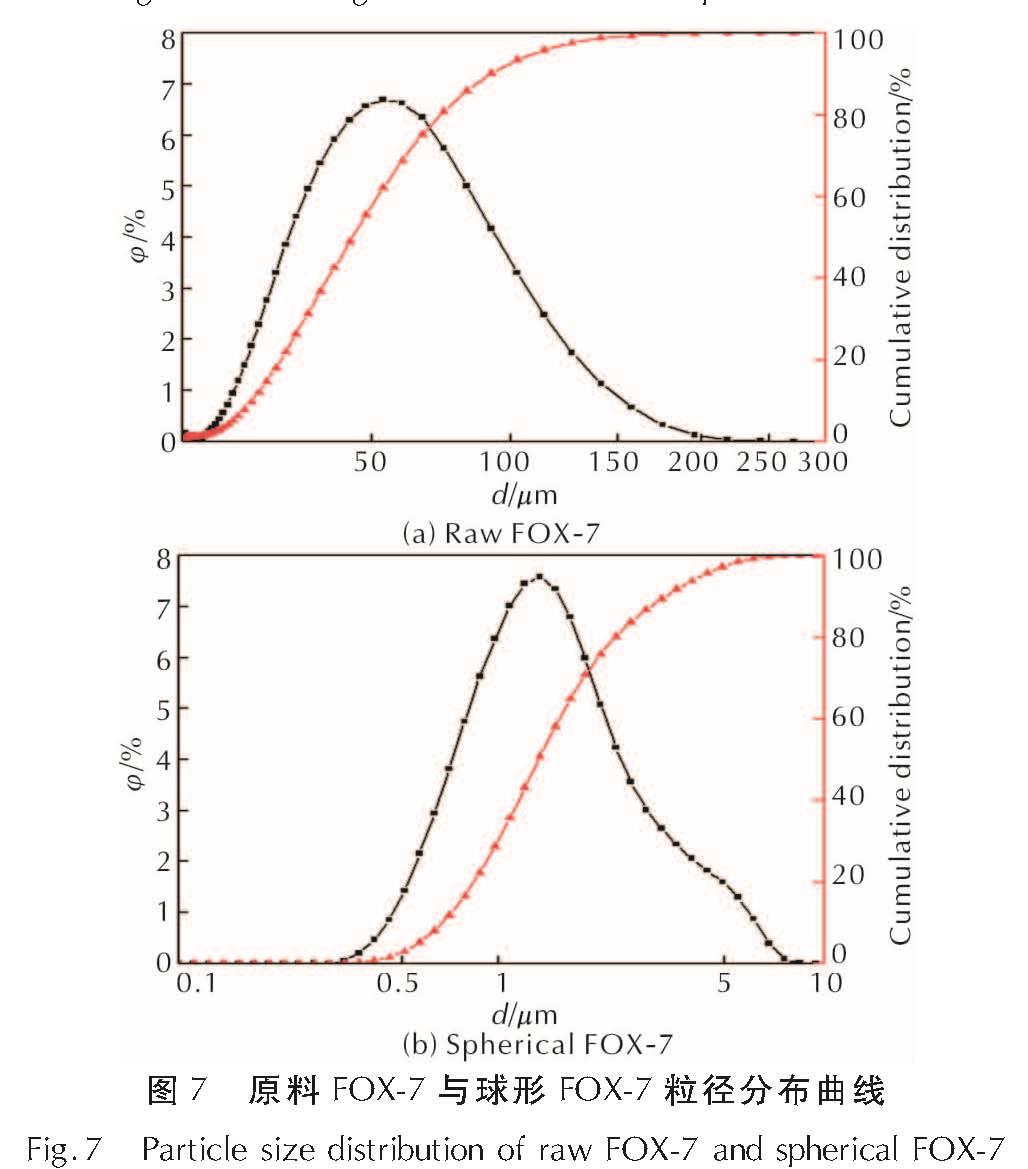

通过自主设计搭建的设备,成功制备得到超细球形FOX-7颗粒,研究了工艺条件(包括溶剂/非溶剂体积比、溶液质量浓度、溶剂和非溶剂温度以及溶剂种类)对喷射结晶过程中FOX-7形貌的影响; 通过扫描电子显微镜、激光粒度分布仪、XRD衍射仪、差示扫描量热仪、热失重分析仪、撞击感度仪以及摩擦感度仪对样品的形貌、粒径分布、晶体结构、热性能以及机械感度进行表征和测试。结果 表明,与原料相比,制备得到的FOX-7颗粒形貌为球形,具有亚微米/微米级别的窄粒度分布(d10=0.703μm,d50=1.405μm,d90=3.446μm),晶体结构稳定; 相比于原料FOX-7,球形FOX-7表观活化能提高了14.62kJ/mol,机械感度明显降低,特性落高提高了42.2cm,摩擦感度较原料相比降低了80%。表明该喷射结晶过程具有产率高、效率高、易于实现大规模生产等优点,有望批量生产亚微米/微米级别的炸药颗粒。

The spherical FOX-7 was prepared successfully by a self-designed equipment, and the effects of different process conditions(such as the volume ratio of solvent/non-solvent, solution mass concentration, the temperature of solvent and non-solvent and different kinds of solvents)on the morphology of FOX-7 prepared by jet crystallization method were studied. The morphology, particle size distribution and crystal structures of all samples were characterized by field emission scanning electron microscopy(FE-SEM), laser particle size instrument and X-ray diffraction(XRD). Thermal analysis was performed by differential scanning calorimetry(DSC)and thermogravimetry(TG), and the impact and friction sensitivities of the samples were also tested. The results show that the spherical submicron/micron FOX-7 particles with a median particle size of 1.405μm, with the particle distribution ranges from 0.703μm(d10)to 3.446μm(d90), were fabricated successfully via jet crystallization method, and the particles exhibited stable structures. The apparent activation energy of spherical FOX-7 is increased by 14.62kJ/mol. The spherical FOX-7 is more insensitive than the raw FOX-7 with an increasement of 42.2cm of characteristic drop height of impact sensitivity and a reduction of 80% of friction sensitivity compared to the raw FOX-7. The jet crystallization method has the advantages of high yield, high efficiency, and achieving large-scale production easily,which has great potential value for the mass production of submicron/micron explosive particles.

引言

随着武器弹药的不断发展,高能钝感炸药在含能材料领域的研究日趋重要。炸药颗粒的不同晶型会导致不同的分子结构与堆积方式,从而影响其安全性能[1]。炸药颗粒热分解过程中的特征反应会发生在晶体缺陷处,对晶体缺陷的研究能够改善其热分解过程[2]。同时,炸药颗粒的形貌、尺寸分布等会影响其在受机械力作用下局部热点的产生,从而影响其机械感度[3-4]。

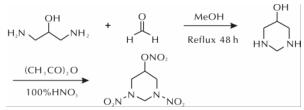

1,1-二氨基-2,2-二硝基乙烯(FOX-7,C2H4N4O4)是一种新型的高能钝感炸药,由瑞典国防研究机构在1998年首次合成[5]。FOX-7有着对称的分子结构和层状的分子堆积方式,拥有较低的感度和较高的热稳定性[6-7]。FOX-7在不敏感弹药[8]及固体推进剂[9]领域拥有广阔的应用前景。Huang等[10]通过喷雾干燥技术制备得到了准三维FOX-7网格,其感度更低,热分解速率更高。Gao等[11]利用超声喷雾辅助静电吸附方法得到了能量,释放更快的纳米/亚微米级别的FOX-7颗粒。Mandal等[12]利用胶束纳米反应器成功制备了亚微米球形FOX-7颗粒,撞击感度略有提高。本课题组通过机械球磨法制备得到了纳米球形FOX-7颗粒,与原料FOX-7相比,纳米球形FOX-7颗粒感度降低,热稳定性有所提高[13]。此外,关于FOX-7的研究主要集中在合成和溶解度等方面。

喷射结晶法作为一种重结晶法,与蒸发结晶法、滴加结晶法、喷雾法等相比,具有效率高、操作简单方便等优点,易于实现规模化生产。王晶禹等[14]首次通过喷射结晶法制备了窄粒度分布、椭球形的超细HMX颗粒。Huang等[15]利用喷管辅助快速沉淀法制备了纳米/亚微米六硝基芪(HNS)颗粒,降低其撞击感度,并研究了重结晶过程中晶型控制剂对HNS形貌和性能的影响。本研究通过自主设计的喷射结晶设备,对FOX-7晶体的喷射结晶过程进行了试验及分析,并对制得的FOX-7颗粒进行了表征及性能测试,以期为快速高效制备亚微米/微米级别的炸药颗粒提供参考。

1 实 验

1.1 材料和仪器FOX-7原料,甘肃银光化学工业集团有限公司; 二甲基亚砜(DMSO),分析纯,天津市凯通化学试剂有限公司; N-甲基吡咯烷酮(NMP),分析纯,上海泰坦科技股份有限公司; N,N-二甲基甲酰胺(DMF),分析纯,天津市申泰化学试剂有限公司; N,N-二甲基乙酰胺(DMA),分析纯,上海易恩化学技术有限公司; 蒸馏水,实验室自制。

喷射结晶设备配件,浙江力高泵业科技有限公司; JP-100S超声波清洗机,深圳市洁盟清洗设备有限公司; HH-WO-5恒温水浴锅,上海一科仪器有限公司; FD-1A-50冷冻干燥机,北京博医康实验仪器有限公司; Mira3场发射扫描电子显微镜(FE-SEM),捷克Tescan公司; Bettersize2000E激光粒度分布仪,丹东百特仪器有限公司; DX-2700型粉末X射线衍射仪(PXRD),丹东浩元仪器有限公司; DSC-800差示扫描量热仪(DSC),上海盈诺精密仪器有限公司; STA449F3热失重分析仪(TG),德国耐驰公司; 撞击感度仪和摩擦感度仪,中国兵器工业传爆药性能检测中心。

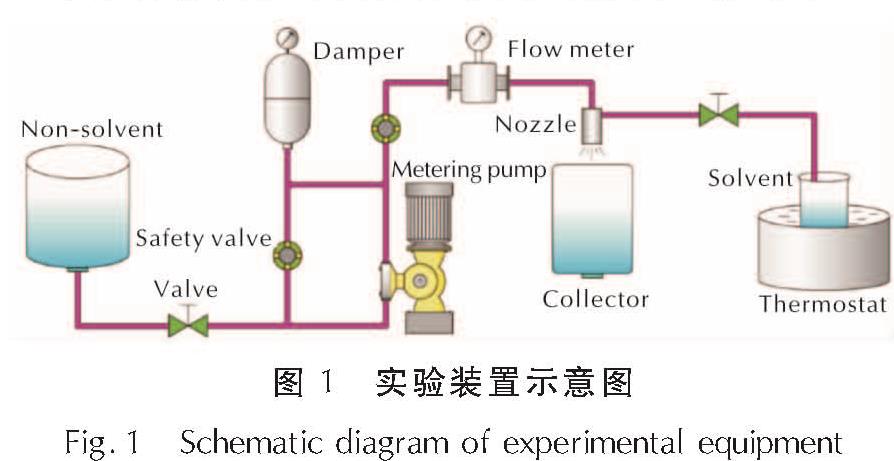

1.2 实验方法自主设计的试验设备示意图如图1所示。

将一定质量的FOX-7在超声辅助下溶解于有机溶剂,配制得到炸药溶液,置于烧杯中,且通过恒温水浴进行温度控制。通过计量泵将非溶剂注入喷管中,以此在喷管中形成负压将炸药溶液吸入喷管,从而使两股流体混合。在两股高速流体混合的过程中,由于其流动速度方向垂直,从而形成横向剪切力,使得炸药颗粒在结晶析出的过程中不易长大,且高速流体之间的碰撞能够将聚集的炸药颗粒打碎,将晶体粒度维持在较小的范围内。另一方面,充满非溶剂的环境也抑制了已析出晶体的二次生长。将含有FOX-7晶体的混合液体收集在容器中,直接对其进行洗涤、过滤、冷冻干燥后得到FOX-7颗粒。本试验装置中计量泵能够准确控制液体流量,保证了混合比例的稳定和准确,且通过安全阀、阻尼器和流量计等设备实时监控流体的流动状态,能够及时处理可能出现的压力过大或液体泄漏等问题,保证了试验过程的安全性。本研究中,3g样品可在约2s内制备完成,说明喷射结晶是一种快速高效的制备方法。

1.3 测试与表征采用场发射扫描电子显微镜对FOX-7原料和重结晶制得的样品进行结构和形貌表征; 采用激光粒度分布仪对样品进行粒度测试; 采用X射线衍射仪对样品进行物相结构和晶型表征,角度范围5°~50°,步进角度0.03°,采样时间0.5s,Cu-Kα射线,管电压40kV,管电流30mA; 采用差示扫描量热仪对样品的热分解特性进行测试,样品质量0.5mg,升温速率分别为5、10、15以及20℃/min; 采用热失重分析仪在20℃/min升温速率下对样品的热失重过程进行测试,氩气环境。

按照GJB 772A-97中601.3撞击感度12型工具法和602.1WM-1型摩擦感度仪,对样品进行撞击感度和摩擦感度测试。撞击感度测试条件:样品质量(35±1)mg,落锤质量(2.500±0.002)kg; 摩擦感度测试条件:样品质量(20±1)mg,摆角90°,表压(3.92±0.07)MPa; 环境温度20~30 ℃,相对湿度60%。

2 实验结果分析

3 球形FOX-7的性能分析

3.1 XRD分析原料FOX-7和球形FOX-7的XRD图谱如图8所示。原料FOX-7在衍射角(2θ)为14.964°、20.037°、20.625°、26.871°、28.038°处的5个特征峰分别对应其晶体的(1 0 1),(1 1 1),(0 1 2),(0 2 0),(0 2 1)晶面,其晶型为α型。

由图8可以看出,通过喷射结晶过程制备得到的FOX-7颗粒的衍射峰位置与原料保持一致,表明制得的样品晶型没有发生改变,仍为α型。另一方面,相比于原料FOX-7,所制得样品的XRD衍射峰强度减弱而峰宽有所增加,这是由于制备得到的球形FOX-7颗粒尺寸比原料FOX-7更小[18]。

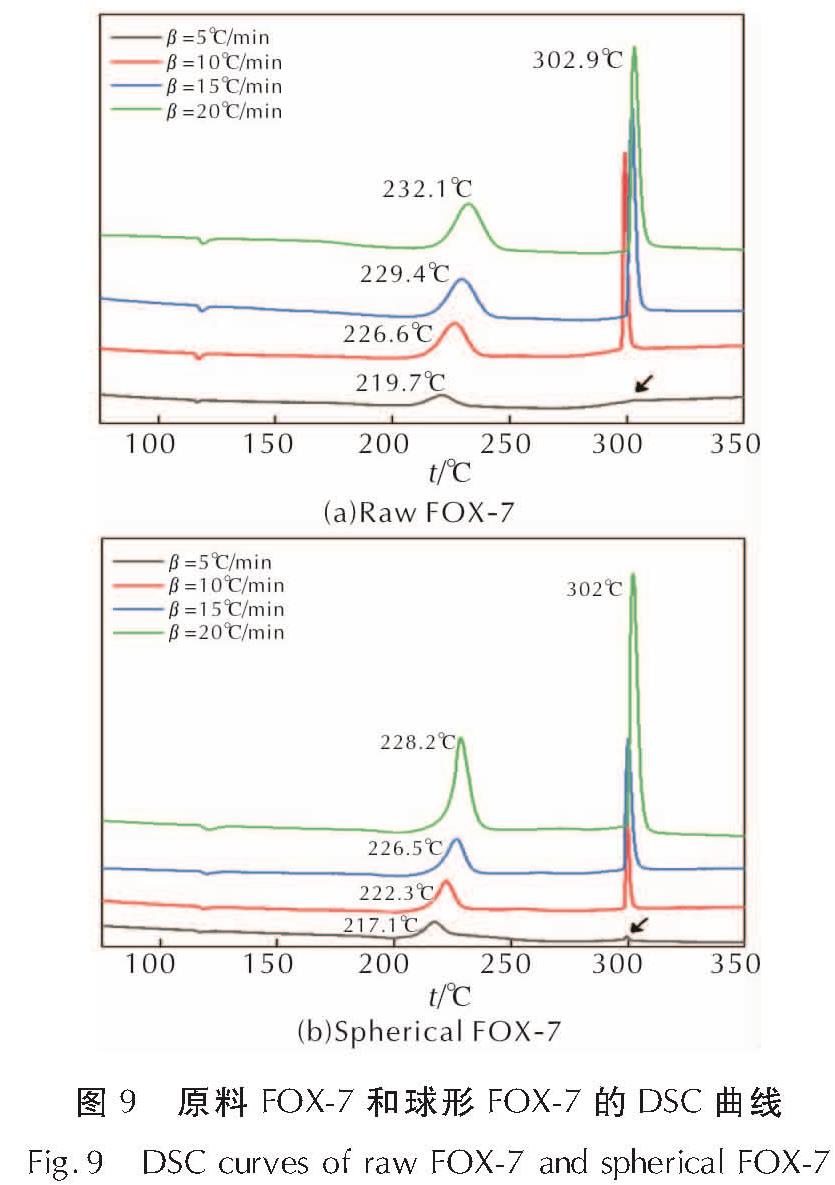

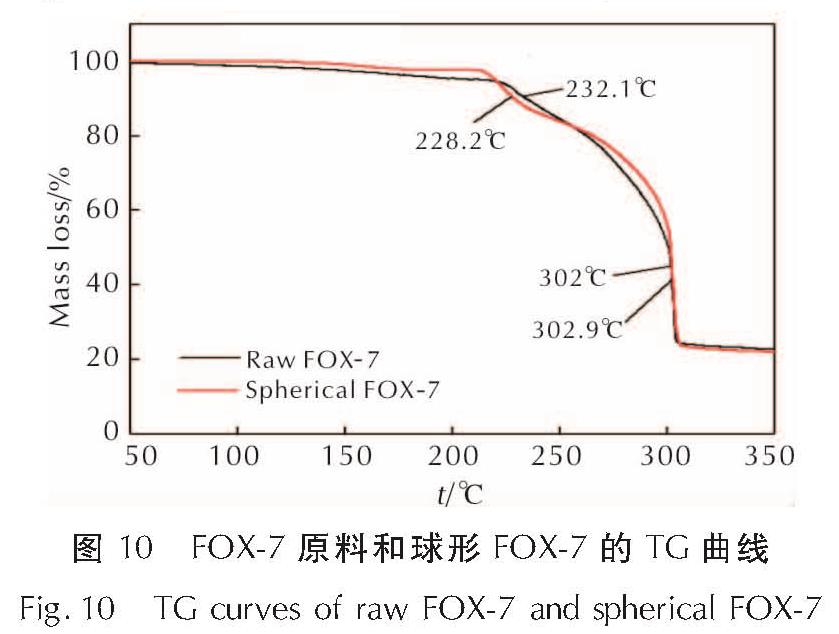

3.2 热性能分析使用差示扫描量热仪(DSC),在升温速率分别为5、10、15以及20℃/min下对样品的热分解特性进行测试,原料FOX-7和球形FOX-7的DSC曲线如图9所示,20℃/min升温速率下的TG曲线如图 10所示。

由图9可以看出,FOX-7的热分解过程存在3个阶段:(1)在110~120℃之间为吸热融化阶段;(2)在210~230℃之间为第一个放热分解阶段;(3)在290~310℃之间为第二个放热分解阶段。第一个分解峰是由FOX-7分子间共轭体系和氢键的破坏引起的[19],而FOX-7分子中碳骨架的断裂导致第二个分解峰的出现[11]。对于每个样品来说,随着升温速率的升高,放热分解峰出现后移,即相对缓慢的升温速率导致最高分解峰温的前移。DSC曲线体现的FOX-7两个热分解过程与TG测试结果相一致。

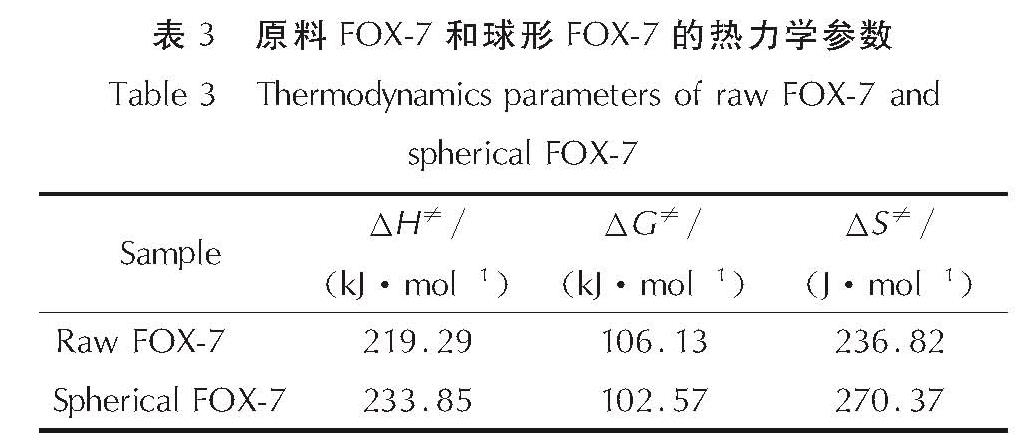

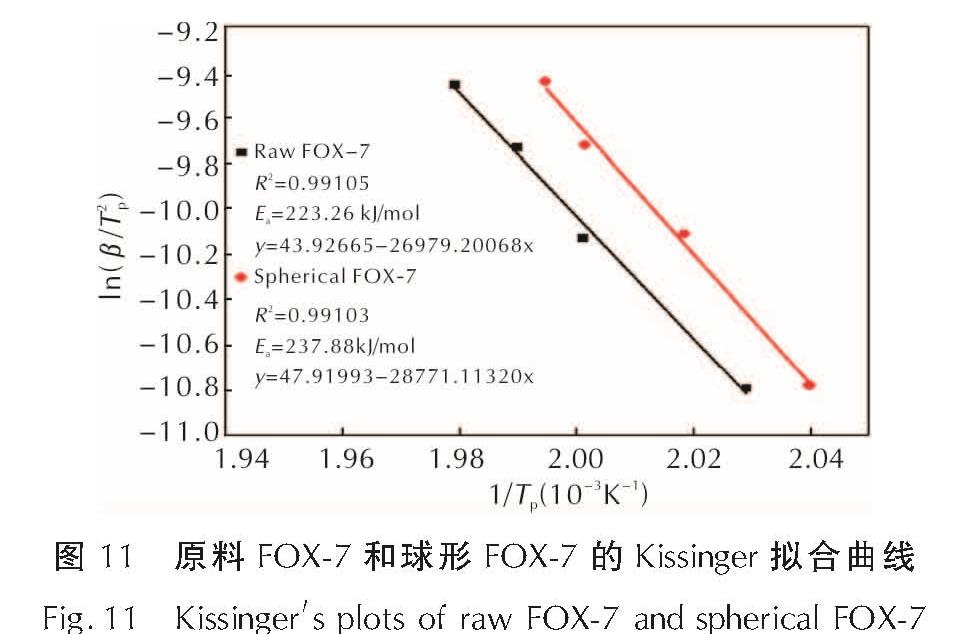

分别利用Kissinger法[20]、Ozawa法[21]和Starink法[22]计算样品的表观活化能,并通过公式(1)和(2)计算样品的热稳定性参数,利用公式(3)~(5)计算样品的热力学参数,结果见表2和表3。

式中:Ti0为温度趋于0时的分解峰温,K; Ti为峰值温度,K; b,c和d为常数; β为升温速率,℃/min; Tb为爆炸临界温度,K; Ea为活化能,kJ/mol; R为气体常数,8.314J/(K·mol); ΔH≠、ΔG≠和ΔS≠分别为样品的活化焓(kJ/mol)、活化自由能(kJ/mol)和活化熵[J/(mol·K)]; k为玻尔兹曼常数(Boltzmann constant),1.381×10-23J/K; h为普朗克常量(Planck constant),6.626×10-34J/s; A为指前因子。

表2 由DSC曲线计算的两种样品的热分解动力学和热稳定性参数

Table 2 Thermal decomposition kinetic and stability parameters of two samples calculated from DSC curves根据DSC曲线及Kissinger法,作出各个样品的Kissinger拟合曲线如图 11所示,每个样品的R2都达到0.99以上,说明计算得到的数据具有较高的可靠性。由表2可知,利用3种方法计算得到的活化能数值比较接近。原料FOX-7的活化能较喷射结晶过程制备得到的球形FOX-7颗粒低,球形FOX-7的表观活化能提高了14.62kJ/mol,且样品的热稳定性参数也有所提高。表观活化能为样品从稳定态到活跃态所需要的能量,据此可知球形FOX-7具有良好的热稳定性。由表3可知,样品的活化自由能(ΔG≠)均为正,表明正常情况下样品均处于稳定状态。ΔH≠为样品从稳定状态到激发状态所吸收的能量,其数值接近于表观活化能。球形FOX-7的活化焓和活化熵最高,说明其从稳定态到激发态所需能量最高,进一步说明球形FOX-7的热稳定性得到提高。

3.3 机械感度分析对两种样品进行撞击感度和摩擦感度测试,得到原料FOX-7特性落高95.3cm,摩擦感度爆炸概率20%; 球形FOX-7特性落高137.5cm,摩擦感度爆炸概率4%。球形FOX-7颗粒的特性落高比原料FOX-7提高了42.2cm,撞击感度大大降低,同时摩擦感度降低了80%。结合两个样品的形貌分析可知,原料FOX-7形貌不规则,为较大尺寸的带有尖锐棱角的块状,而球形FOX-7粒径较小,形貌较规则。根据“热点”理论,在受到机械撞击过程中,颗粒之间的空隙会经历绝热压缩,形成许多“热点”,导致爆炸。而球形FOX-7颗粒更小,比表面积增加,在受到机械撞击和摩擦时,机械力会通过颗粒表面快速传递,被分散至更多的表面,从而使得机械感度大大降低。

与文献[23]相比,本研究所用喷射结晶法更易获得球形FOX-7颗粒,能够实现大批量连续量产,产率较高。且本研究获得的球形FOX-7颗粒摩擦感度与文献[23]相当,而撞击感度更低。

4 结 论

(1)通过自主设计的喷射结晶试验装置,得到通过喷射结晶过程制备球形FOX-7的最佳工艺条件为:水为非溶剂,二甲基亚砜为溶剂,温度20℃,溶剂/非溶剂的体积比为1:12,溶液的质量浓度为0.3g/mL。

(2)制备得到的球形FOX-7形貌规则、颗粒表面光滑,且具有亚微米/微米级别的窄粒度分布,d10=0.703μm,d50=1.405μm,d90=3.446μm。

(3)球形FOX-7的热稳定性有所提高,表观活化能比原料FOX-7提高了14.62kJ/mol; 机械感度有明显改善,特性落高较原料FOX-7相比提高了42.2cm,摩擦感度降低了80%。

2.1 工艺条件优化研究不同试验条件对喷射结晶过程中FOX-7颗粒形貌的影响,从而选择出最优工艺条件。从溶剂/非溶剂体积比、溶液质量浓度、溶剂/非溶剂温度以及溶剂种类等方面对FOX-7喷射结晶过程进行研究:(1)根据试验设备设置5个不同溶剂/非溶剂体积比(1:3、1:6、1:9、1:12和1:15);(2)根据FOX-7在二甲基亚砜(DMSO)中的溶解度[16](见表1),等间隔设置不同的溶液质量浓度,分别为0.1、0.2、0.3、0.4g/mL以及饱和溶液(约为0.43g/mL);(3)设置不同溶剂/非溶剂温度,研究溶剂温度在20、40和60℃、非溶剂温度在0℃(冰水混合物)及20℃下FOX-7形貌的变化;(4)研究不同溶剂对FOX-7形貌和粒径的影响,根据表1溶解度数据研究DMSO、N-甲基吡咯烷酮(NMP)、二甲基甲酰胺(DMF)以及二甲基乙酰胺(DMA)对FOX-7结晶过程的影响。

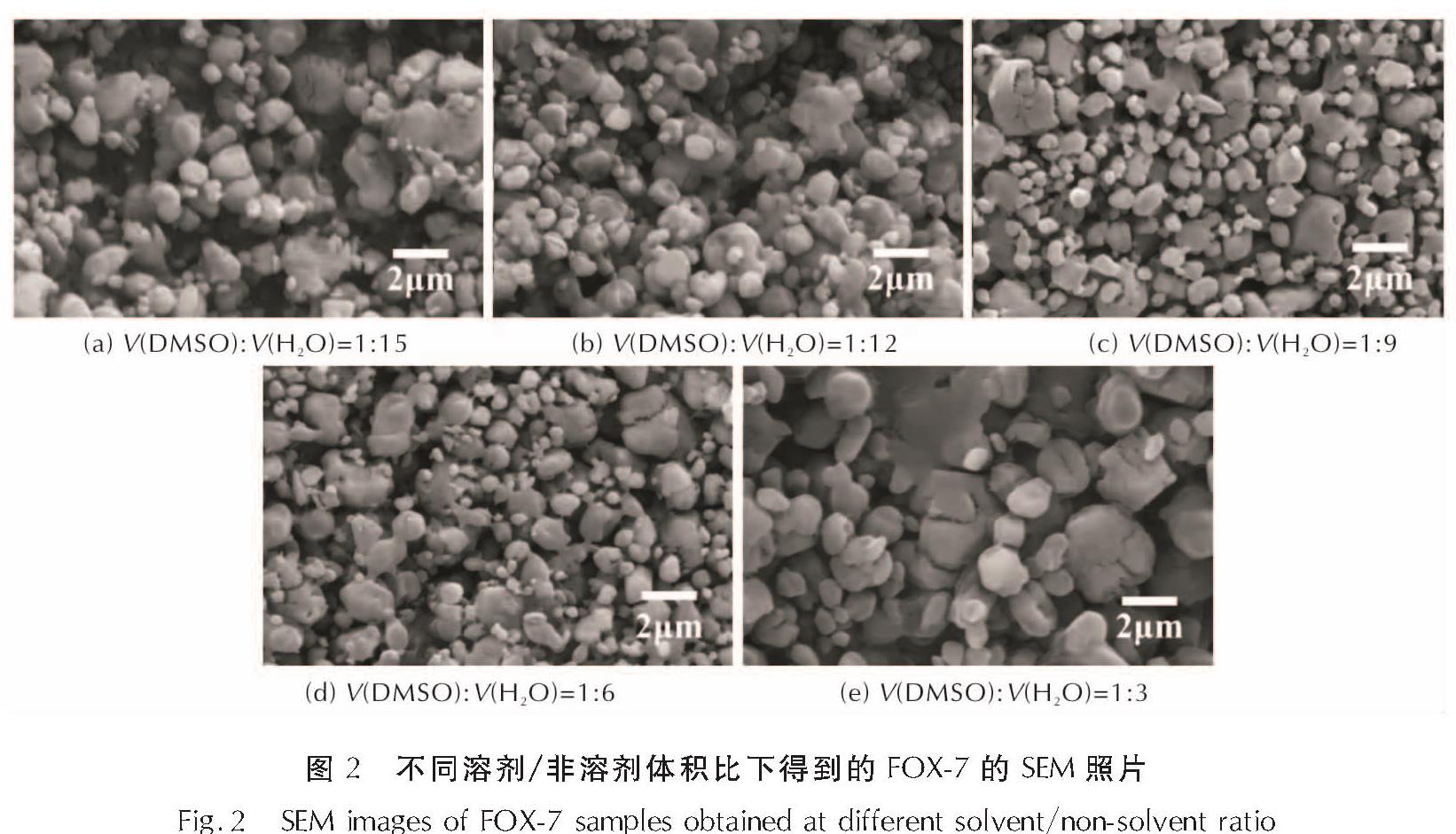

2.1.1 溶剂/非溶剂体积比的影响在常温下,制备0.3g/mL的FOX-7/DMSO溶液,通过调节计量泵流量控制旋钮,以控制进入喷管的非溶剂流量,从而达到溶剂和非溶剂不同的混合比。不同溶剂、非溶剂混合比条件下FOX-7颗粒的SEM照片见图2。

图2 不同溶剂/非溶剂体积比下得到的FOX-7的SEM照片

Fig.2 SEM images of FOX-7 samples obtained at different solvent/non-solvent ratio由图2可知,当溶剂/非溶剂体积比较大时,制备得到的FOX-7颗粒粒径分布较均匀,形貌为类球形颗粒; 当溶剂/非溶剂体积比较小时,得到的颗粒大小不均匀,且形貌不规则,出现较大的块状颗粒,且粒径呈现不均匀分布。分析认为,当溶剂/非溶剂体积比较小时,非溶剂量相对较少,晶核间距较小,FOX-7晶体之间碰撞减少,容易造成晶体聚集长大; 当非溶剂体积较大时(1:12或1:15),流体碰撞形成的剪切力较大,形成很多小的液滴,晶体的生长受到限制,且流体和晶体之间的碰撞导致大的晶体不易形成,所以得到的类球形颗粒粒径较小,且分布均匀。喷射结晶过程的高速流体混合过程使得晶体析出和生成的时间大大缩短,同时混合过程中较强的湍流减弱了溶质分子从液相向粒子表面的扩散,减小了晶体的介稳区,更易获得超细颗粒[14]。比较溶剂/非溶剂体积比为1:12和1:15两组FOX-7颗粒,当体积比为1:12时,颗粒形貌更规则,颗粒尺寸分布更集中,所以选择最优溶剂/非溶剂体积比为1:12。

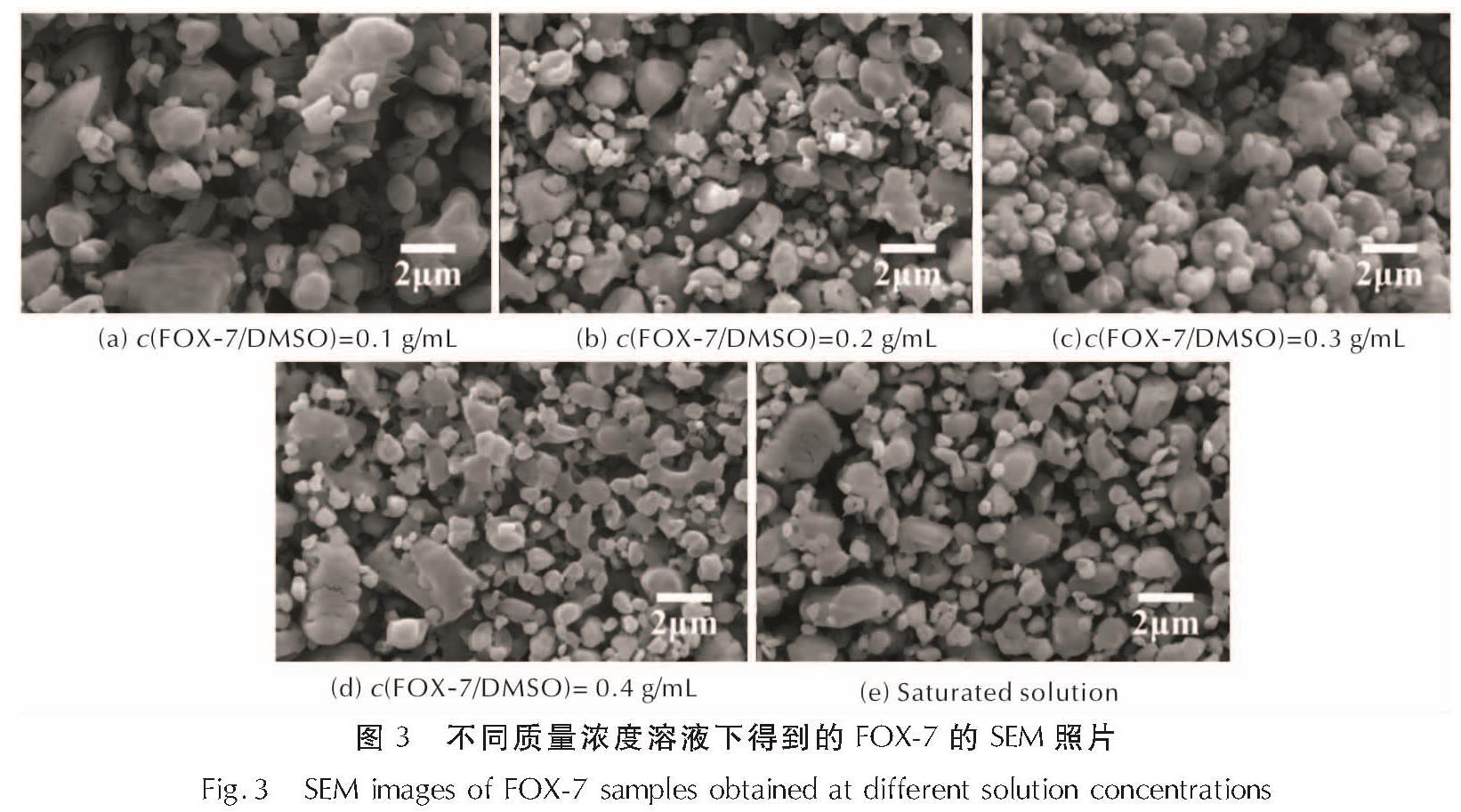

2.1.2 溶液质量浓度的影响在溶剂/非溶剂体积比为1:12的条件下,配置不同质量浓度的炸药溶液(0.1、0.2、0.3、0.4g/mL及饱和溶液),得到的FOX-7重结晶颗粒的SEM照片如图3所示。

图3 不同质量浓度溶液下得到的FOX-7的SEM照片

Fig.3 SEM images of FOX-7 samples obtained at different solution concentrations根据图3可知,在溶液质量浓度较小时(0.1和0.2g/mL),制备得到的颗粒很不规则,尤其是0.1g/mL时,存在长径比较大的块状颗粒,且粒径分布很不均匀; 当溶液质量浓度为0.3g/mL时,得到类球形FOX-7颗粒,且大小均匀; 当质量浓度继续增加时,出现颗粒较大的不规则FOX-7,粒径分布不均匀。分析认为,当溶液质量浓度较小时,溶剂含量相对较大,溶解于溶剂中的溶质分子会在晶核上不断析出,导致颗粒较大; 当溶液质量浓度较大甚至饱和时,溶质分子含量较多,晶核碰撞机率增加,晶体成核速率和生长速率都很大,在一定范围内成核速率大于生长速率时,会产生大量的晶核,从而得到大小不一、形貌不规则的晶体[16]; 当溶液质量浓度适中时(0.3g/mL),在流体碰撞形成的横向剪切力和颗粒碰撞的双重作用下,得到形貌规则、尺寸分布均匀的颗粒。因此选择最优溶液质量浓度为0.3g/mL。

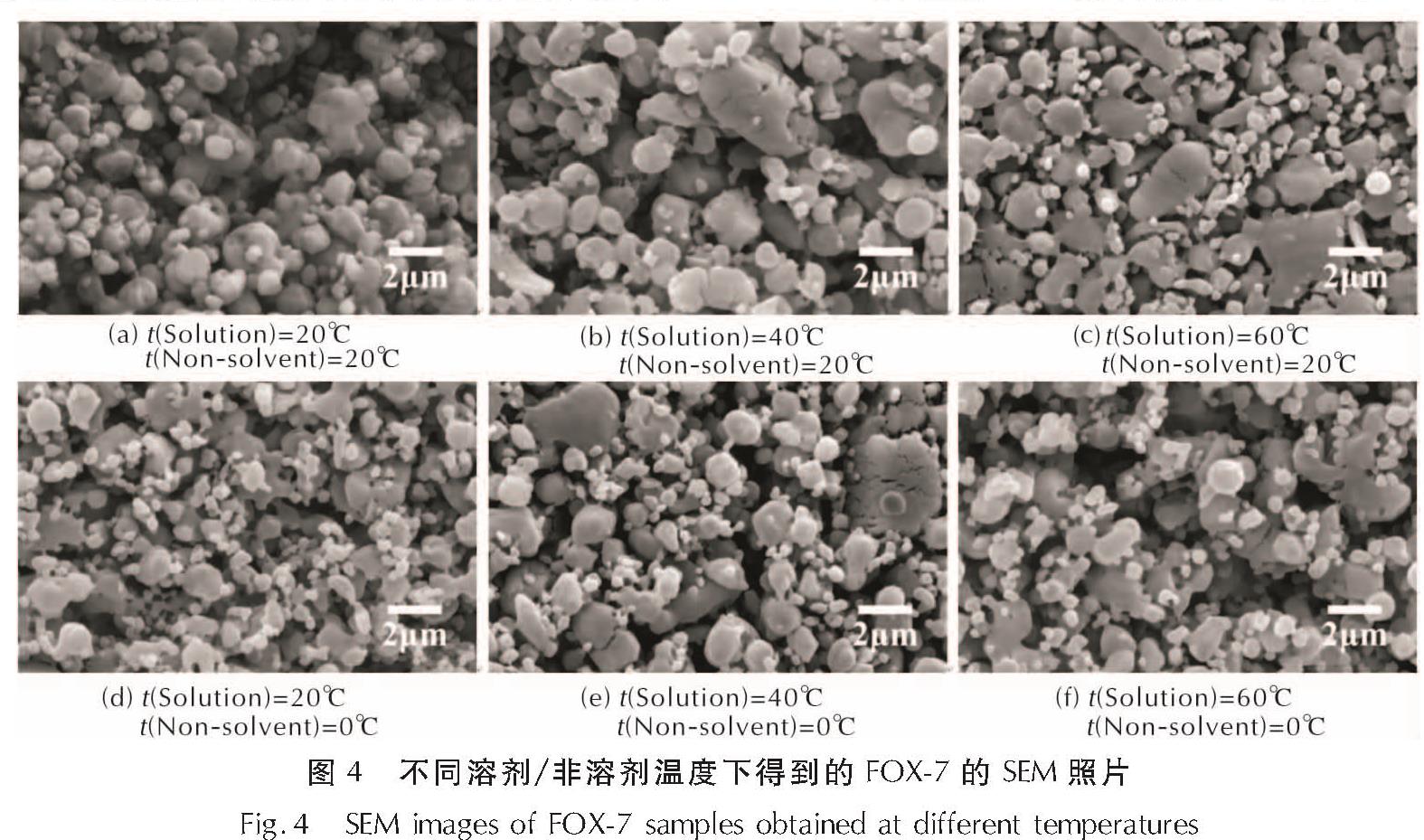

2.1.3 溶剂/非溶剂温度的影响在溶剂/非溶剂体积比为1:12,溶液质量浓度为0.3g/mL的条件下,改变溶剂和非溶剂的温度,在非溶剂温度在20℃和0℃(冰水混合物)下分别设置3个溶剂温度(20℃、40℃和60℃),制备得到FOX-7颗粒的SEM照片如图4所示。

由图4可知,当非溶剂温度接近0℃时,得到的FOX-7存在许多小颗粒,随着溶剂温度升高,出现部分较大颗粒,颗粒尺寸出现不均匀分布; 当非溶剂温度为20℃时,细小晶体较少,且当溶剂温度较高时,出现较大颗粒,当溶剂温度和非溶剂温度均为20℃时,得到的晶体形貌规则,颗粒尺寸分布均匀。分析认为,当非溶剂温度为0℃时,由于非溶剂量较多(溶剂/非溶剂体积比为1:12),晶体生长环境温度较低,分子动能较低,FOX-7分子运动减缓,影响了体系中成核速率和生长速率的比率,导致出现很多细小晶体; 当非溶剂温度为20℃、溶剂温度较高时,晶体成核速率和生长速率较快,使得溶质分子向晶核聚集速率加快,导致生成许多大颗粒。所以选择最优温度为溶剂20℃、非溶剂20℃。

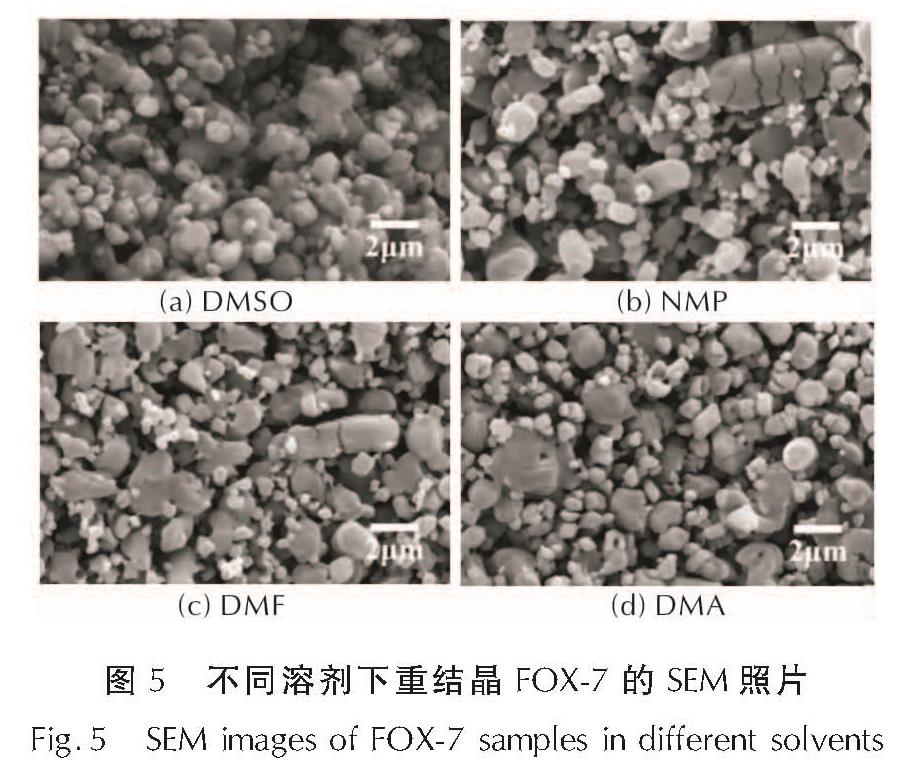

2.1.4 溶剂种类的影响在溶剂/非溶剂体积比为1:12,溶液质量浓度0.3g/mL,溶液温度20℃,非溶剂温度20℃的条件下,选择DMSO、NMP、DMF和DMA为溶剂,制备得到FOX-7颗粒的SEM照片如图5所示。

由图5可知,以DMSO为溶剂制得的FOX-7颗粒形貌规则、颗粒尺寸分布均匀; 以NMP和DMF为溶剂得到的FOX-7颗粒尺寸不均匀,存在长径比较大的长棒状颗粒,且晶体表面出现裂纹; 以DMA为溶剂得到的FOX-7颗粒在1μm左右存在许多小颗粒,但存在较大颗粒,且出现部分颗粒带有棱角。FOX-7在不同溶剂中结晶形貌的不同,与重结晶过程中,溶剂的极性以及其与晶面生长的相互作用有关[16-17]。当溶剂对某些晶面的生长起阻碍作用时,晶体在该晶面的生长较慢; 当溶剂对某些晶面的生长起促进作用时,该晶面的生长相对较快,导致晶体长径比较大,晶体出现棱角等。从晶体生长的角度看,溶剂分子与各晶面的结合能对晶体生长影响较大,结合能越大,对晶体晶面生长的抑制作用越大。根据图5不同溶剂下重结晶FOX-7颗粒的SEM照片,推测在喷射结晶过程中,溶剂DMSO与FOX-7晶体各晶面的结合能大小较均匀,所以晶体能够在各晶面均速增长,从而得到形貌较规则的类球形FOX-7; 而当溶剂为NMP、DMF和DMA时,溶剂分子与FOX-7各晶面之间的结合能相差较大,导致FOX-7晶体在某些晶面生长较快,形成形貌不规则的FOX-7颗粒。因此选择DMSO为最佳溶剂。

- [1] 田贝贝, 陈丽珍, 张朝阳. HMX分子与晶体结构性能研究进展[J]. 含能材料, 2019, 27(10): 883-892.

- [2]金韶华,松全才.炸药理论[M]. 西安:西北工业大学出版社,2010: 55-56.

- [3]ZHANG Yong-xu, LIU Da-bin, Lü Chun-xu. Preparation and characterization of reticular nano-HMX[J].Propellants, Explosives, Pyrotechnics, 2005, 30(6):438-441.

- [4]SONG Xiao-lan, WANG Yi, AN Chong-wei, et al. Dependence of particle morphology and size on the mechanical sensitivity and thermal stability of octahydro-1,3,5,7-tetranitro-1,3,5,7-tetrazocine[J]. Journal of Hazardous Materials, 2008, 159(2/3):222-229.

- [5]LATYPOV N V, BERGMAN J, LANGLET A, et al. Synthesis and reactions of 1,1-diamino-2,2-dinitroethylene[J]. Tetrahedron, 1998, 54(38): 11525-11536.

- [6]BEMM U, ÖSTMARKH. 1,1-Diamino-2,2-dinitroethylene: a novel energetic material with infinite layers in two dimensions[J]. Acta Crystallographica. Section C, Crystal Structure Communications, 1998, 54(12):1997-1999.

- [7]BELLAMY A J. FOX-7(1,1-Diamino-2,2-dinitroethene)[J]. Structure and Bonding, 2007, 125: 1-33.

- [8]CULLIS I G, TOWNSLEY R. The potential of FOX-7 explosive in insensitive munition design[J]. Journal of Applied Mechanics, 2011, 78(5):051012.

- [9]JENSEN T L, UNNEBERG ERIK, KRISTENSEN T E. Smokeless GAP-RDX composite rocket propellants containing diaminodinitroethylene(FOX-7)[J].Propellants, Explosives, Pyrotechnics, 2017, 42(4): 381-385.

- [10]HUANG Bing, QIAO Zhi-qiang, NIE Fu-de, et al. Fabrication of FOX-7 quasi-three-dimensional grids of one-dimensional nanostructures via a spray freeze-drying technique and size-dependence of thermal properties[J]. Journal of Hazardous Materials, 2010, 184(1/3):561-566.

- [11]GAO Bing, WU Peng, HUANG Bing, et al. Preparation and characterization of nano-1,1-diamino-2,2-dinitroethene(FOX-7)explosive[J]. New Journal of Chemistry, 2014, 38(6): 2334-2341.

- [12]MANDAL A K, THANIGAIVELAN U, PANDEY R K, et al. Preparation of spherical particles of 1,1-diamino-2,2-dinitroethene(FOX-7)using a micellar nanoreactor[J]. Organic Process Research & Development, 2012, 16(11):1711-1716.

- [13]XU Rui-xuan, AN Chong-wei, HUANG Hao, et al. Preparation of multi-scale FOX-7 particles and investigation of sensitivity and thermal stability[J]. RSC Advances, 2019, 9(36): 21042-21049.

- [14]王晶禹,张景林, 王保国. HMX炸药的重结晶超细化技术研究[J]. 北京理工大学学报, 2000, 20(3):385-388.

- [15]WANG Jing-yu, HUANG Hao, XU Wen-zheng, et al. Prefilming twin-fluid nozzle assisted precipitation method for preparing nanocrystalline HNS and its characterization[J]. Journal of Hazardous Materials, 2009, 162(2/3):842-847.

- [16]刘璐.高能低感炸药FOX-7的结晶研究[D].绵阳:西南科技大学,2018.

- [17]CELEBRE G, DE LUCA G, MAIORINO M, et al. Solute-solvent interactions and chiral induction in liquid crystals[J]. Journal of the American Chemical Society, 2005, 127(33):11736-11744.

- [18]SHI Xiao-feng, WANG Jing-yu, LI Xiao-dong, et al. Preparation and characterization of HMX/Estanenanocomposites[J]. Central European Journal of Energetic Materials, 2014, 11: 433-442.

- [19]GINDULYT A, MASSA L, HUANG L, et al. Proposed mechanism of 1,1-diamino-dinitroethylene decomposition: a density functional theory study[J]. The Journal of Physical Chemistry A, 1999, 103(50):11045-11051.

- [20]KISSINGER H E. Reaction kinetics in differential thermal analysis[J]. Analytical Chemistry, 1957, 29(11): 1702-1706.

- [21]OZAWA T. A new method of analyzing thermogravimetric data[J]. Bulletin of the Chemical Society of Japan, 1965, 38(11): 1881-1886.

- [22]STARINK M J. Analysis of hydrogen desorption from linear heating experiments: accuracy of activation energy determinations[J]. International Journal of Hydrogen Energy, 2018, 43(13): 6632-6641.

- [23]李小东, 杨武, 刘慧敏, 等. 喷雾重结晶法细化FOX-7及性能表征[J/OL]. 火炸药学报.DOI:10.14077/j.issn.1007-7812.201907006.