作者简介:王华煜(1991- ),男,硕士研究生,从事含能材料研究。E-mail:wanghy@163.com

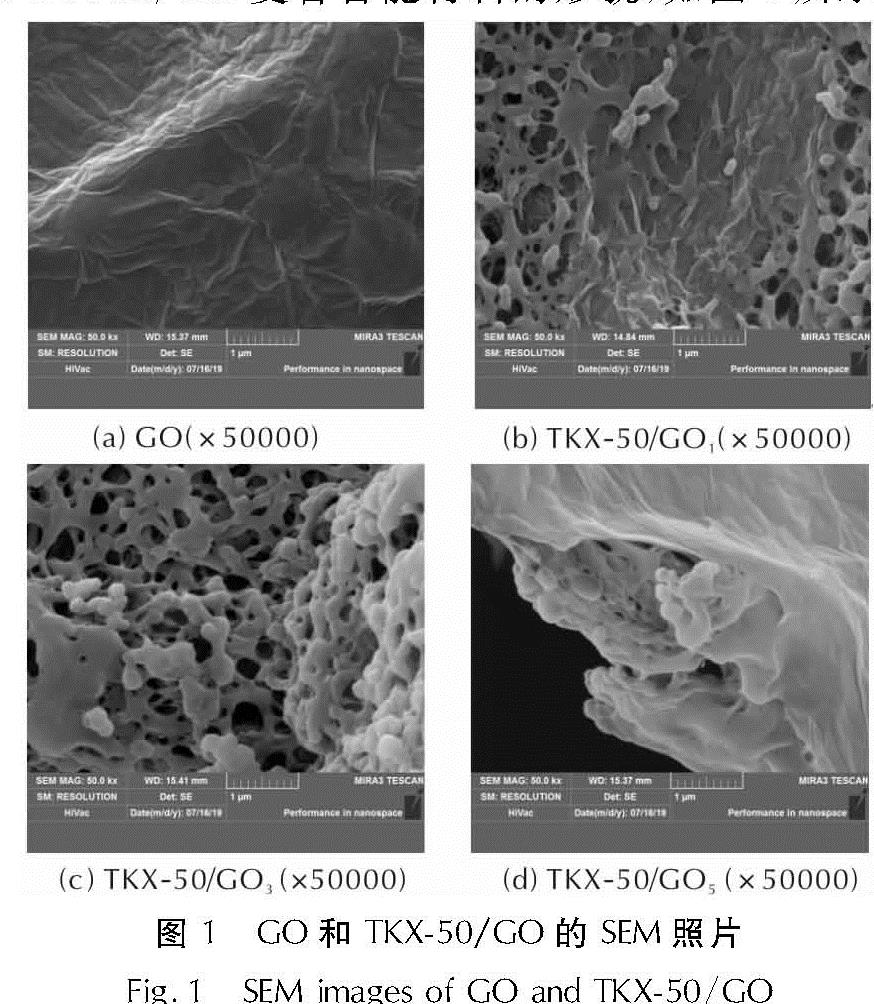

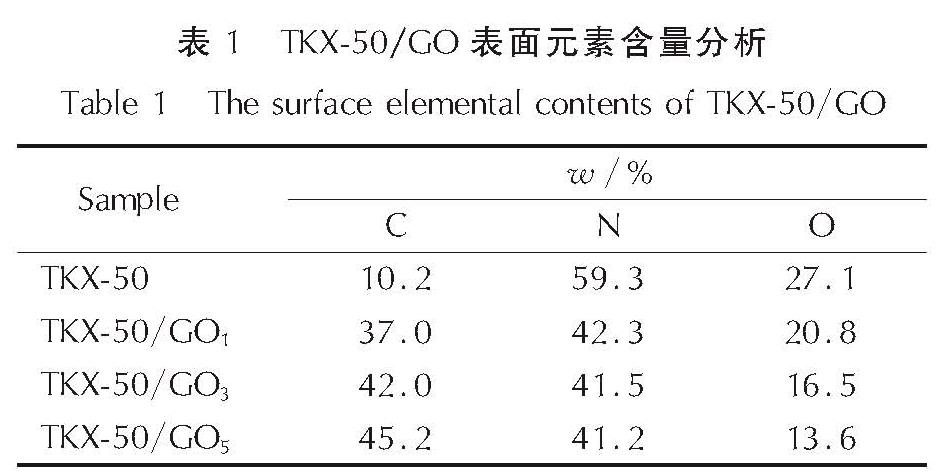

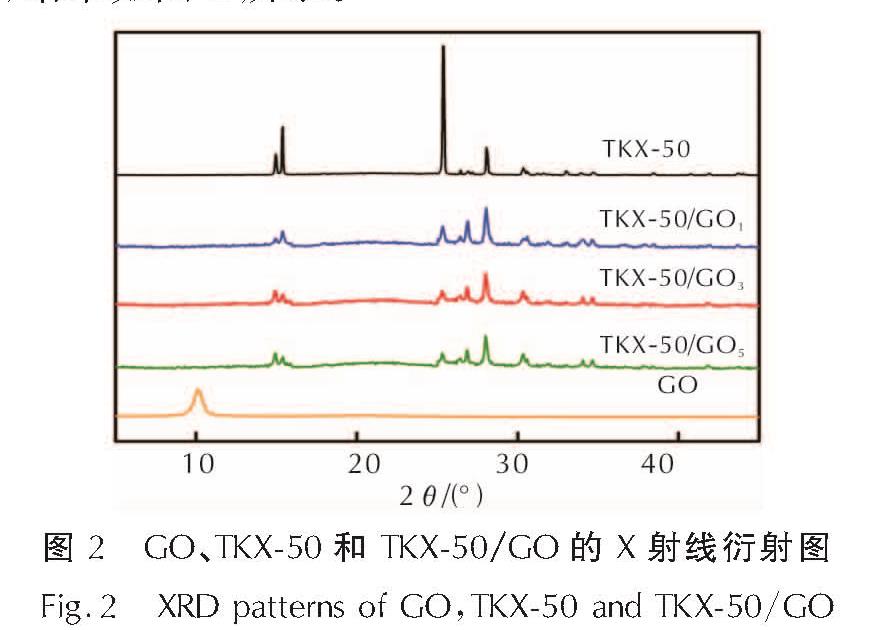

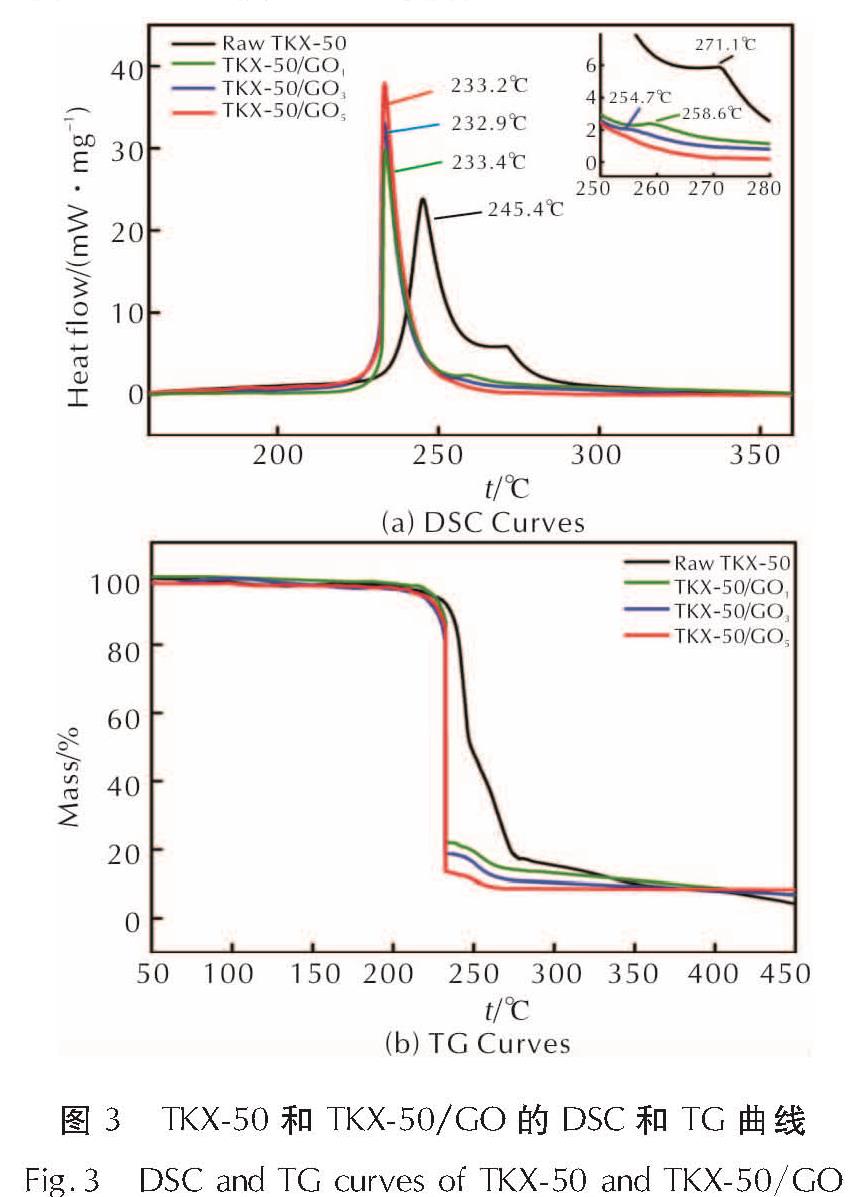

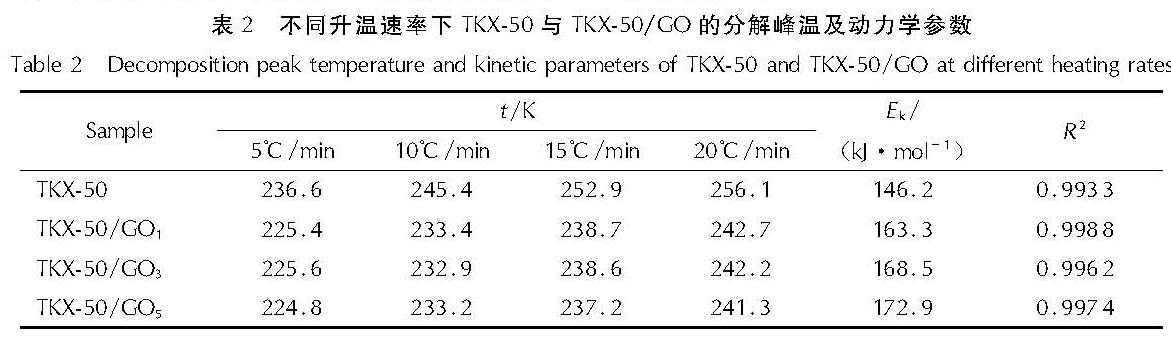

为了研究5,5'-联四唑-1,1'-二氧二羟胺(TKX-50)/氧化石墨烯(GO)纳米复合含能材料的热分解性能,采用液氮喷雾冷冻干燥法,制备了TKX-50/GO复合材料; 通过扫描电子显微镜-能谱仪(SEM-EDS)、X射线衍射仪(XRD),对样品的形貌、结构以及表面元素含量进行了表征和分析; 采用热重-差示扫描量热法(TG-DSC)分析了复合材料的热分解性能; 采用Kissinger法计算了其表观活化能。结果 表明,采用液氮冷冻喷雾干燥法制备的TKX-50/GO复合材料具有纳米级层状网络结构; 与TKX-50相比,TKX-50/GO复合含能材料的第一阶段分解峰峰温向低温方向移动12.0、12.5、12.2℃,第二阶段分解峰峰温向低温方向移动12.5℃和16.4℃,随着GO含量的增加,第二阶段分解峰变得不明显,TKX-50/GO5两个分解阶段重叠,表观活化能从146.2kJ/mol提高到163.3、168.5和172.9kJ/mol。GO提高了复合含能材料的活化能垒,使分解峰温提前,缩短了反应区间时间,从而提高了能量释放速率,促进了TKX-50/GO复合材料的热分解。

In order to study the thermal decomposition properties of 5,5'-bistetrazole-1,1'-diolate(TKX-50)/graphene oxide(GO)nano-composite energetic materials, liquid nitrogen-assisted spray freeze-drying method was used to prepare TKX-50/GO composite materials. The morphology, structure and surface element of the samples were characterized and analyzed by using the scanning electron microscopy-energy spectroscopy(SEM-EDS)and X-ray diffraction(XRD). The thermal decomposition properties of composites were analyzed by using the thermogravimetry-differential scanning calorimetry(TG-DSC). The apparent activation energy was calculated by using the Kissinger method. The results show that the TKX-50/GO composite prepared by liquid nitrogen-assisted freeze spray drying method has nano-scale layered network structure. Compared to the TKX-50, the first stage decomposition peak temperature of TKX-50/GO composite energetic material decreases by 12.0, 12.5 and 12.2℃, and the second stage decomposition peak temperature decreases by 12.5℃ and 16.4℃. With the increase of GO content, the decomposition peak in the second stage is not obvious, and the two decomposition stages of TKX-50/GO5 are overlapped. The apparent activation energy of the nano-composite materials increases from 146.2kJ/mol to 163.3, 168.5 and 172.9kJ/mol compared to the TKX-50, respectively. GO improves the activation energy barrier of the composite energetic material, decreases the decomposition peak temperature and shortens the reaction interval time, so the GO improves the energy release rates and promotes the thermal decomposition of TKX-50/GO composite materials.