作者简介:梁宁(1998-),男,从事炸药配方工艺研究。E-mail:793376406@qq.com 通信作者:冀威(1987-),男,博士,从事含能材料配方及改性研究。E-mail:jiwei 7327@163.com

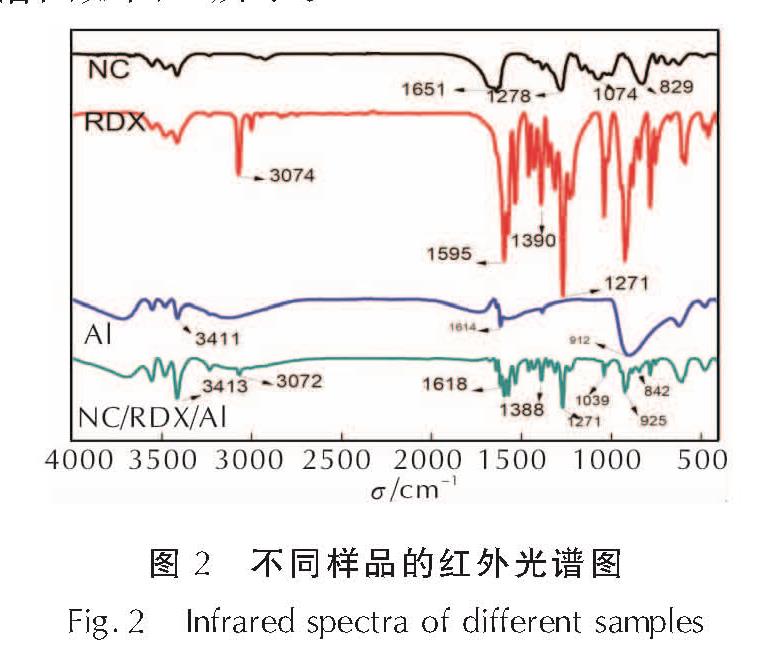

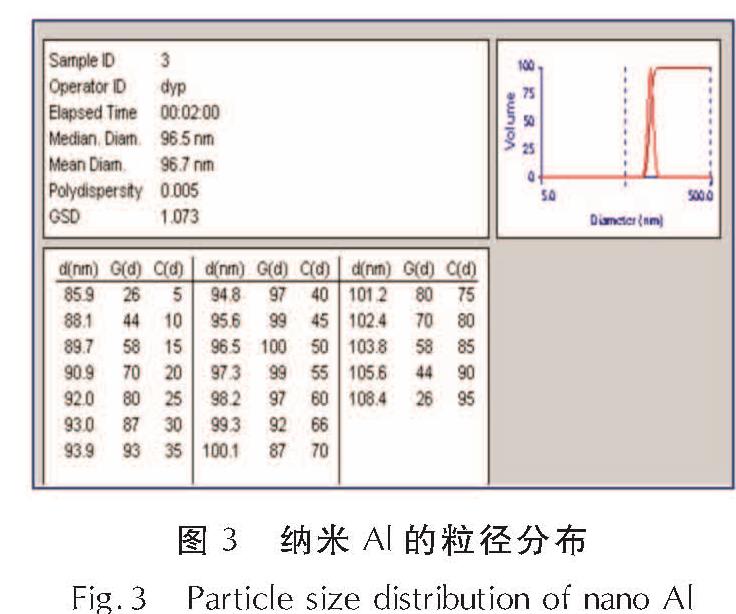

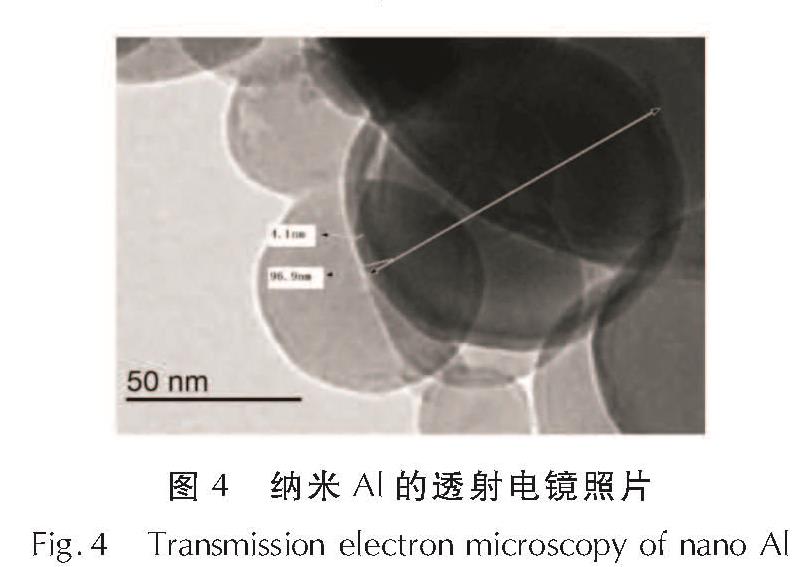

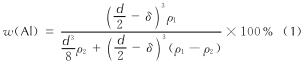

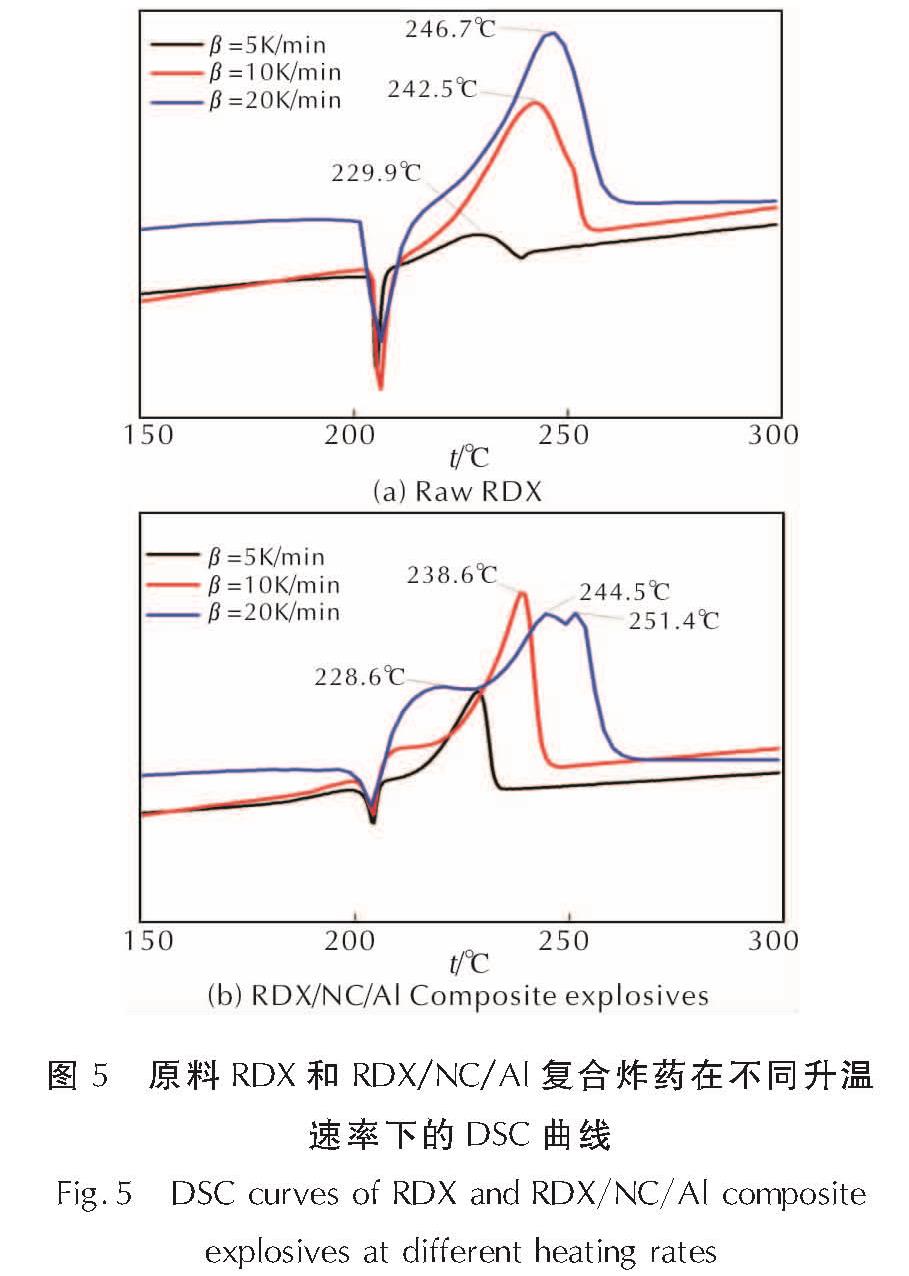

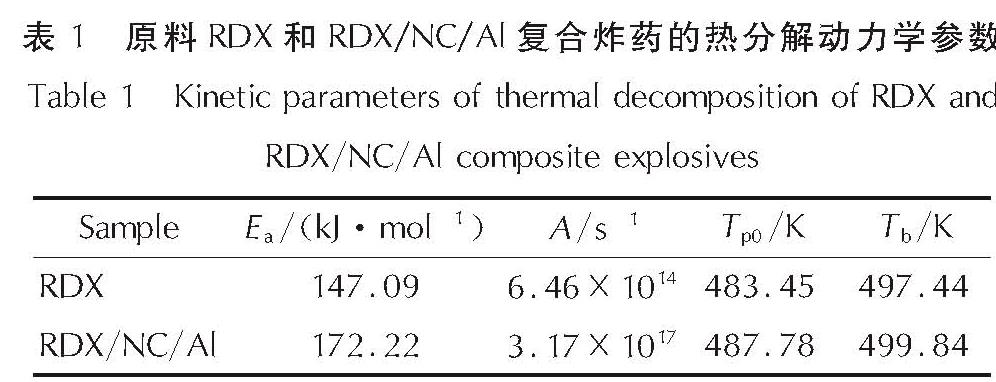

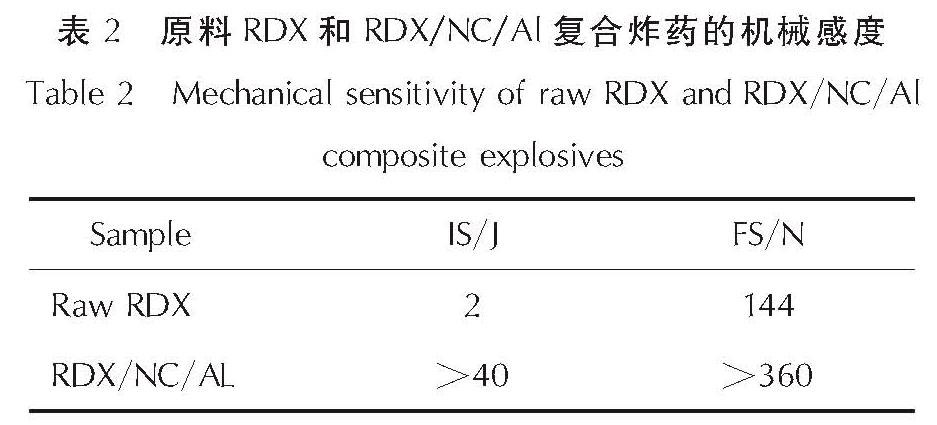

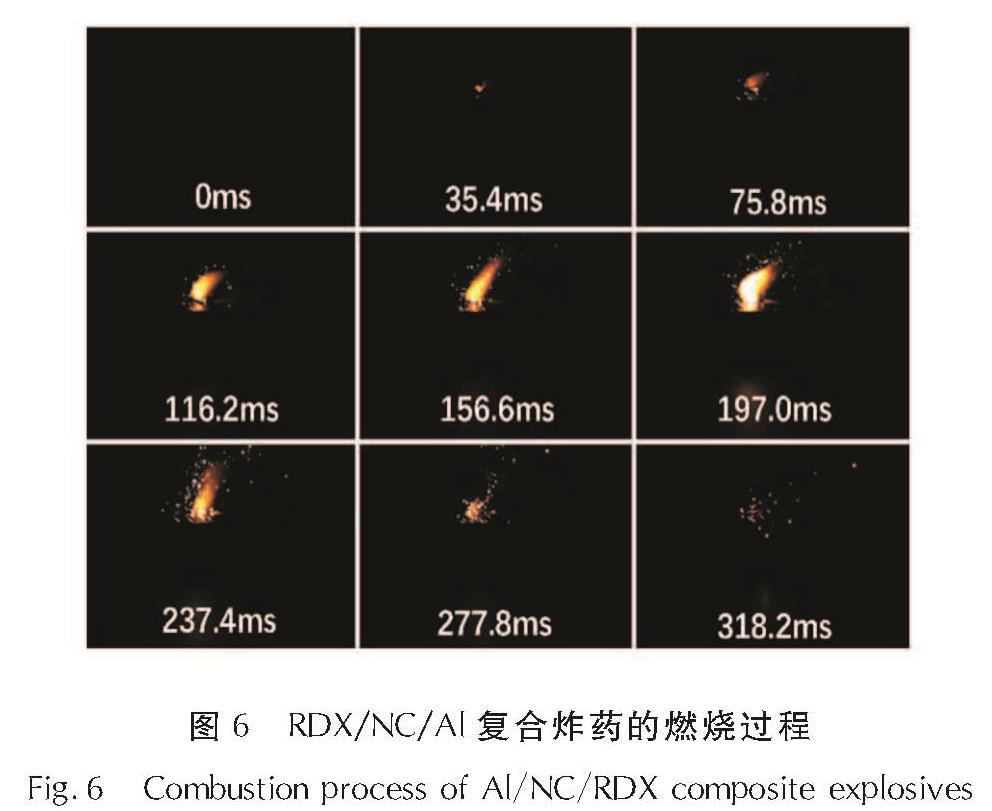

为改善环三次甲基三硝基胺(RDX)的能量密度和反应速率,采用静电喷雾法制备了RDX/NC/Al复合炸药; 通过扫描电子显微镜(SEM)和傅里叶变换红外光谱(FT-IR)对产品的形貌、结构进行分析,利用透射电镜法对纳米Al进行活性分析,采用热重-差示扫描量热(TG-DSC)对产品热性能进行了分析,同时测定了其机械感度,并用高速摄影仪分析其燃烧过程。结果 表明,采用静电喷雾法制得的RDX/NC/Al复合炸药的粒径范围为60~170nm,以团聚微球的形式存在,3种原料之间的复合为物理复合,纳米Al粉的铝质量分数约为74.89%; 与原料RDX相比,RDX/NC/Al复合炸药的活化能提高了25.11kJ/mol,热爆炸临界温度提高了2.4℃,两者的等动力学温度为214.69℃,撞击感度和摩擦感度分别大于40J和360N,降感效果明显。表明RDX/NC/Al复合炸药的燃烧性能较好,具有较短的点火延迟时间和较高的燃烧速率,以及较好的安全性能。

In order to improve the energy density and reaction rate of cyclotrimethyltrinitroamine(RDX), electrostatic spray method was applied to prepare RDX/NC/Al composite explosives.The appearance and structure of the composite explosives were analyzed by using scanning electron microscope(SEM)and fourier transform infrared spectroscopy(FT-IR). The activity of Al nanoparticles was analyzed by using TEM. Thermogravimetric analysis-differential scanning calorimetry(TG-DSC)was used to analyze the thermal performance of the product, and the mechanical sensitivity was measured. The combustion process was analyzed by using high-speed photography. The results show that the particle size of RDX/NC/Al composite explosive prepared by electrostatic spraying method ranges from 60nm to 170nm, which exists in the form of agglomerated micro-spheres. The composite mode among the three materials is physical composite. The aluminum mass fraction of nano Al powder is about 74.89%. Compared with the raw material RDX, the activation energy of RDX/NC/Al is increased by 25.11kJ/mol and the critical thermal explosion temperature is increased by 2.4℃. The isodynamic temperature of the RDX and RDX/NC/Al is 214.69℃. The composite explosive has obvious effect of decreasing the sensitivity, and the sensitivity of impact and friction are greater than 40J and 360N, respectively. Therefore, the product has better combustion performance with shorter ignition delay time, higher combustion rate and better safety performance.