作者简介:王为民(1992-), 男, 博士研究生, 从事纳米材料研究。E-mail: 1633541139@qq.com 通信作者:赵凤起(1963-), 男, 博导, 研究员,从事固体推进剂及含能材料研究。E-mail: zhaofqi@163.com

(1. 西安近代化学研究所, 陕西 西安 710065; 2. 西北大学 化工学院, 陕西 西安 710069)

(1. Xi'an Modern Chemistry Research Institute, Xi'an 710065, China; 2. School of Chemical Engineering, Northwest University, Xi'an 710069, China)

applied chemistry; nanotechnology; electrospinning; polymer processing; composites; nano-energetic nanofibers

DOI: 10.14077/j.issn.1007-7812.201911003

备注

作者简介:王为民(1992-), 男, 博士研究生, 从事纳米材料研究。E-mail: 1633541139@qq.com 通信作者:赵凤起(1963-), 男, 博导, 研究员,从事固体推进剂及含能材料研究。E-mail: zhaofqi@163.com

概述了静电纺丝设备基本的工作原理及主要过程工艺参数对产物组成和表面形貌结构的影响,其原理为高压电场中的聚合物溶液在静电力作用下克服表面张力进行射流拉伸、鞭动细化,最后在接收装置上形成纳米纤维。综述了静电纺丝工艺在超级铝热剂、单质含能材料和固体燃料纳米化及爆炸物荧光检测领域的应用研究进展。研究结果表明,静电纺丝技术是调控材料形貌特征和实现含能材料纳米化的一种有效方法,在铝热剂型含能材料中能够有效抑制纳米Al粉颗粒的表面氧化和预反应烧结现象、提高颗粒分散性和增加传质传热速率。同时,含能材料纳米化对改善材料燃烧分解特性、提高能量密度、降低感度、增强含能材料力学性能等有显著的效果。展望了静电纺丝功能化纳米复合含能材料在今后的研究方向和应用前景。

The working mechanism of electrospinning apparatus and the effects of main process parameters on the composition and morphology of fibers are introduced in detail. The basic principle is that charged droplet in the high-voltage electric field overcomes the surface tension of the polymer solution as a function of electrostatic force and then undergoes a stretching and whipping process, leading to finally the formation of long and thin nanofibers on a grounded collector. In addition, the recent progress of the application of electrospinning technique in the field of superthermites, nanocrystallization of single energetic materials and solid fuels, and the ultrasensitive fluorescence detection of explosives is reviewed.The results show that the electrospinning technique is an effective method to control the morphology of nanofibers and achieve the nano-crystallization of energetic materials. It can effectively inhibit the surface oxidation and pre-reaction sintering of nano aluminum particles for the thermite-type energetic materials. Also, it can increase the dispersion of particles and improve the reaction efficiency and the heat release of reaction.Meanwhile, the nano-crystallization of energetic materials by the electrospinning technique has remarkable effects on improving the combustion decomposition characteristics, increasing the energy density, reducing the sensitivity, and enhancing the mechanical properties of energetic materials. Finally, the future research trends and application of electrospinning functionalized nano-energetic composites are also prospected.

引言

含能材料被广泛应用于弹药、航空航天、采矿和焊接等领域。设计和制备高能量密度、高释能效率和低感度的复合含能材料是未来含能材料发展的重要方向[1-2]。纳米材料尺度处于原子簇和宏观物体交界的过渡区域,是一种典型的介观系统,呈现出独特的理化性质,具有一系列独特的效应,如表面效应、小尺寸效应等[3]。含能材料纳米化在改善燃烧分解性能、增加反应深度、增大放热量,提高能量释放速率和燃烧速率,降低含能材料感度,增强力学性能等方面表现出显著的优势。特别是纳米复合含能材料中具有较大比表面积和长径比的纳米复合含能纤维,在提高材料能量特性、改善力学性能的同时,还能有效抑制单一纳米粉体颗粒的团聚、提高分散性,实现不同材料的有机结合,获得性能优异的功能复合材料。

纳米复合纤维的制备方法有多种,如拉伸法、模板法、相分离法、自组装法和静电纺丝法等[4-6]。其中,静电纺丝法以操作简单、成本低廉、过程连续、生产效率高、应用范围广等优点引起人们的高度关注,现已成为直接制备纳米纤维材料的主要方法之一。静电纺丝法制备的纳米复合纤维具有较大比表面积、较高孔隙率、高柔韧性、大长径比和超强机械性能等特性,被广泛应用于纳米传感器、光催化、过滤阻隔材料、电极材料、智能穿戴、生物医疗等领域[7-10]。静电纺丝过程中,通过工艺参数的调节,可以实现纤维直径在几十纳米到几微米范围内的可控调节,从而满足不同领域的应用需求[11-13]。同时,改变聚合物基质溶液的组成,可以得到具有不同表面结构和功能的纳米纤维复合材料,进而满足不同领域对纤维材料的差异化功能需求[14-15]。

将含能单质与功能添加剂通过静电纺丝技术引入到纤维基体中可以得到功能化的纳米复合含能纤维材料。在这些纤维中,各组分间紧密接触,有效缩短了分子间的反应距离,加快了含能材料的反应速率和传质传热进程,从而能够显著提高含能材料燃烧分解速率、能量水平和释放效率,同时通过引入特定的组分如氧化石墨烯等可以降低含能材料的感度,进而增强含能材料的综合应用性能[16-17]。静电纺丝工艺作为一种简单且高度通用的技术,在复合含能材料制备中体现出极大的潜在应用价值。本文概述了静电纺丝设备的工作原理及主要工艺参数对产物组成和表面结构形貌的影响,并对静电纺丝技术在含能材料中的已有应用研究进行了综述,以期为其在含能材料中的进一步推广应用和研究提供参考。

1 静电纺丝技术

静电纺丝技术最早可追溯至16世纪英国皇家医学院院长Gilbert发现的液体静电引力现象,其被认为是静电纺丝的萌芽[18]。其后,1934年Formhals Anton发明了静电纺丝实验装置,并用醋酸纤维素的丙酮溶液首次制备得到聚合物纤维,成功实现了静电纺丝技术由基础理论研究到具体实践的跨越,被认为是静电纺丝技术制备微纳米纤维的开端[19]。时至今日,随着纳米科学技术的发展和静电纺丝技术研究的不断深入,静电纺丝技术已成为制备表面结构和直径可控的有机/无机功能化微纳米复合纤维的有效方法[20]。

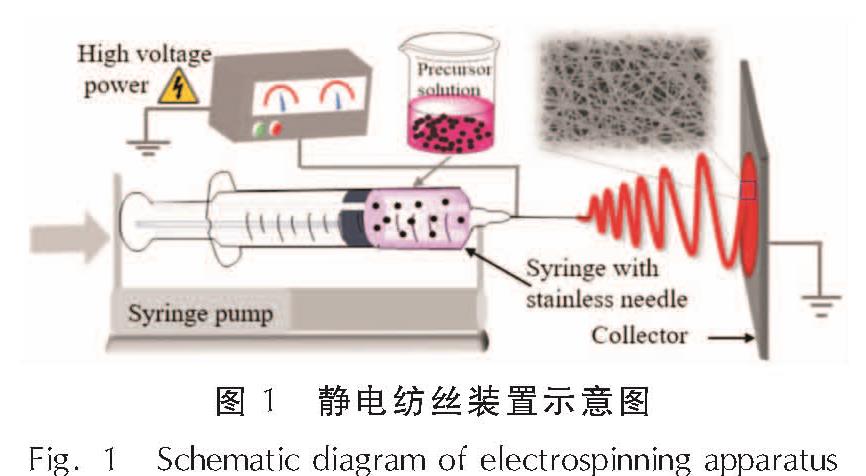

1.1 静电纺丝的基本原理图1为典型的静电纺丝装置和基本工作原理示意图。一套完整的静电纺丝装置通常由高压静电发生器、带有金属喷射针头的注射器、注射泵和接收器4部分组成[18, 21]。基本工作原理可以概述为处在高压电场中的聚合物溶液或熔体等黏弹性流体液滴即Taylor锥(又称泰勒锥,锥角一般为49.3°)克服其表面张力和黏弹力,在静电力作用下经过快速的喷射拉伸、鞭动细化、溶剂挥发和固化,最后得到粗细均匀的聚合物纤维,并最终由于带电射流的弯曲不稳定性以螺旋形式沉积在接地的接收装置上[22-23]。

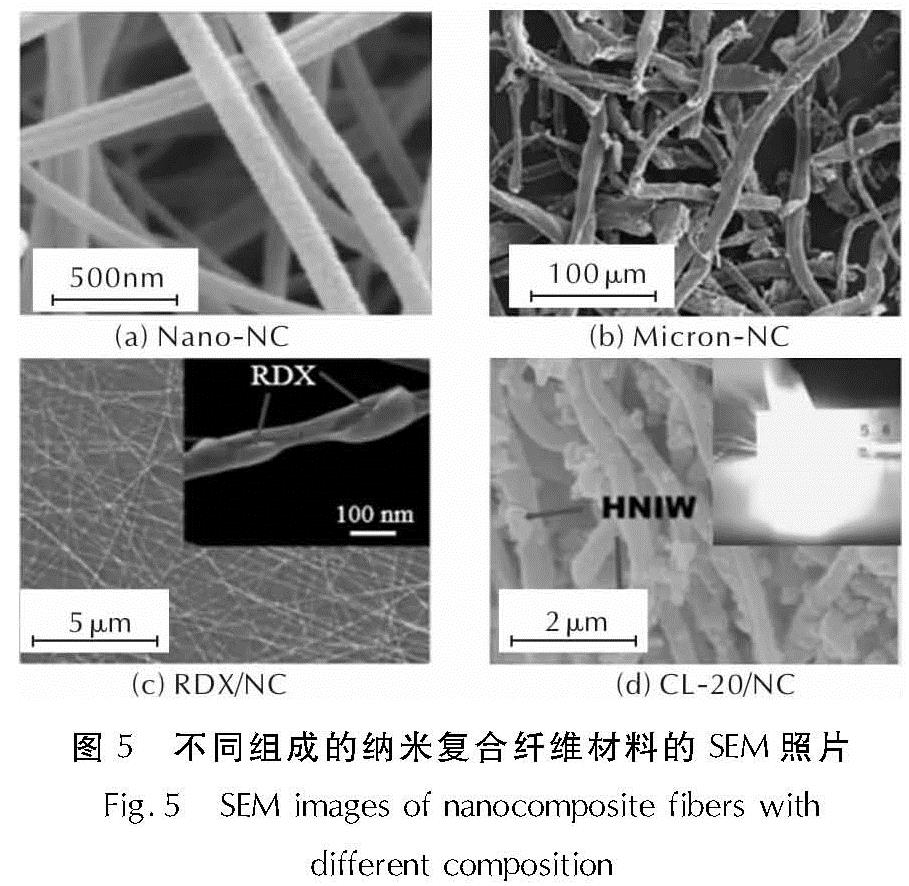

1.2 影响静电纺丝过程的主要参数影响静电纺丝过程的主要参数包括前驱体聚合物溶液性质、设备控制参数和环境因素3个方面。前驱体聚合物溶液性质包括溶液的浓度、黏度、表面张力、介电常数、电导率、化学组成、聚合物相对分子质量等,其中溶液黏度是静电纺丝纤维形成的基础,决定着纤维产物的组成结构和形貌[10, 24-25]。溶液黏度与聚合物自身的相对分子质量成正比,在一定的黏度范围内,低黏度的聚合物溶液有利于射流在电场中拉伸细化得到长径比较大的纤维[26-27]。对溶液电导率和表面张力而言,纺丝液电导率越大、表面张力越小,越有利于得到较细结构的纤维。在前驱体溶液中添加离子液体、盐类物质、金属粒子和表面活性剂等可以提高溶液的电导率、降低表面张力[10, 28-29]。设备工艺参数包括工作电压、进料速率、接收距离、喷丝头内径等。工作电压和接受距离的变化会引起电场强度的变化,从而影响射流的拉伸及纤维产物的结构和长径比。进料速率通过蠕动泵控制,对泰勒锥的形成和射流的连续性有显著的影响,在保证射流连续形成的基础上,纤维直径随着进料速率的增大而减小[30]。环境因素包括温度、湿度和气压等,其主要通过影响纺丝液的性质和射流拉伸过程中溶剂的挥发速率间接影响纤维的形态[30-32]。

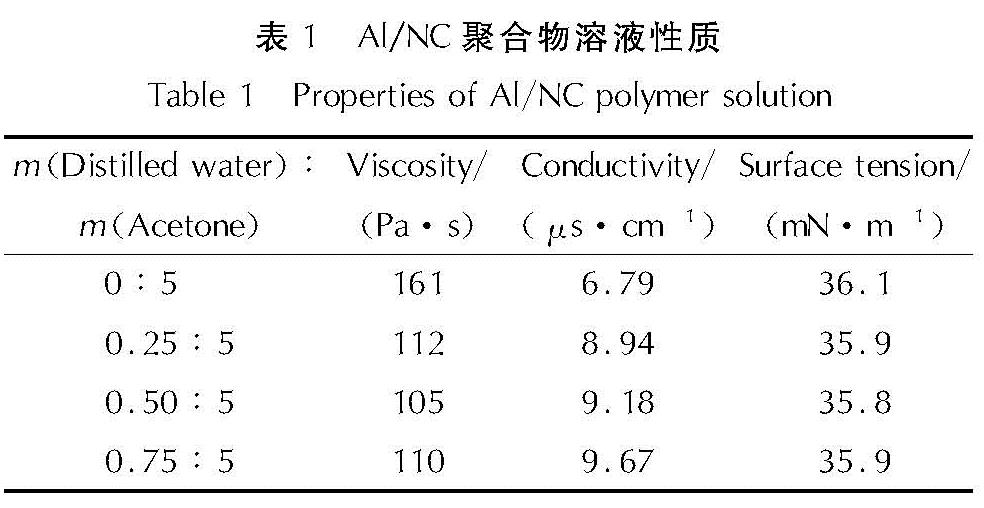

Xie等[25]详细研究了聚合物溶液性质(见表1和图2)和电压对Al/NC复合纤维形貌的影响。由图2可知,当聚合物溶液黏度和电导率较低时,静电纺丝过程中前驱体溶液的拉丝行为较差,纤维产物中有较多块状材料出现。随着聚合物溶液黏度和电导率的增大、表面张力的减小,产物中块状材料逐渐减少,得到直径均匀和表面光滑的纳米纤维。

图2 不同质量比去离子水和丙酮的混合溶液纺丝得到的Al/NC纤维

Fig.2 SEM images of Al/NC fibers obtained by electrospinning with different mass ratio of distilled water to acetone静电纺丝纤维的形成是多种因素综合作用的结果,其中纺丝液黏度的影响最为关键,决定着纤维产物的组成和表面结构,同时还影响着过程工艺参数的确定。环境因素的变化会引起纺丝液理化性质的改变进而间接影响纤维的尺寸和形貌特征。静电纺丝过程中各种参数之间相互作用、彼此影响,共同促成了不同组成、结构和形貌的超细功能化纳米纤维的形成。

2 静电纺丝技术在纳米复合含能材料领域的应用

2.1 在铝热剂型复合含能材料中的应用超级铝热剂材料由于能量密度大、反应剧烈、能量释放效率高等特性被广泛应用于固体推进剂中[3],它能够显著提高推进剂的能量密度、燃烧速率、燃烧温度及比冲等,进而从多方面改善火箭的弹道性能。同时,氧化铝(Al2O3)作为铝热反应的主要产物之一,具有较高的熔点,是一种高效的燃烧稳定剂,能够有效抑制推进剂的高频不稳定燃烧,从而实现推进剂的高效稳态燃烧。此外,铝热反应的产物——过渡金属单质对双基、改性双基或复合推进剂等含能组分的热分解与燃烧也具有较好的催化作用[33]。

传统的超级铝热剂材料制备方法有很多,如溶胶-凝胶法[34]、超声分散复合法[35]、水热法[3]、浸渍法[3]等,这些方法得到的超级铝热剂材料由于Al粉颗粒表面存在预反应烧结现象和Al2O3薄膜(颗粒表面氧化),使得铝热反应的效率有一定程度降低。同时,当氧化物和燃料处于纳米尺度时,纳米颗粒由于较大的表面能存在一定的团聚现象,对铝热剂的能量释放效率也造成了一定的不利影响[36-37]。静电纺丝技术以高分子聚合物为基,将铝热剂的不同组分通过静电纺丝技术复合能有效抑制纳米铝粉颗粒的表面氧化和预反应烧结现象以及解决微纳米粒子的团聚问题。同时,不同组分间形成的正协同催化效应,有利于进一步提升含能材料的综合应用性能。

近年来,国内外研究人员在利用静电纺丝制备铝热剂型复合含能材料方面开展了大量的工作。Yan等[33]制备了硝化棉(NC)/Al-CuO复合含能纤维并研究了其燃烧行为,如图3所示。由图3可知,纳米Al粉和CuO颗粒被均匀包覆在NC纤维中,颗粒间的团聚现象被显著抑制。高速摄影法测得NC、NC/Al、NC/Al-CuO的燃速分别为12.4、4.8和106cm/s,NC/Al-CuO的火焰传播速率最快、燃烧过程最为剧烈,火焰结构最为明亮。NC/Al-CuO复合纤维燃烧性能的显著提高归因于纤维材料中纳米Al粉和CuO颗粒间的紧密接触,其加快了铝热反应过程中质量和能量的传递速率,从而使得反应速率和燃烧效率增加,表明纳米尺度的铝热剂能够明显提高燃速。

图3 NC/Al-CuO纳米复合纤维的SEM和TEM图及其w—v曲线和纤维的燃烧火焰图

Fig.3 SEM, TEM images and the w—v curve of NC/Al-CuO nanocomposite Fibers, and the burning snapshots of the fibers with different compositionsLi等[38]将NC作为气体发生剂,通过静电纺丝技术将其与Al粉和Fe2O3颗粒复合制备了Al/Fe2O3/NC复合纤维(如图4(a)所示),并与NC及NC/Al纤维对比研究了其热分解特性和力学性能。热分析结果表明,Al/Fe2O3/NC复合纤维的热分解温度较NC显著降低、放热分解峰半峰宽变窄,热分解反应速率显著提高。复合纤维热分解特性的提升归因于其较大的比表面积及NC与Fe2O3和Al粉颗粒间的紧密接触,各组分间的紧密接触有效减小了热阻,加快了传质传热进程。同时,Fe2O3也是NC热分解过程的催化剂,能够加速O―N键的断裂,对加快复合纤维分解速率也有重要作用。此外,复合纤维中的高焓值Al粉对提高复合材料的能量特性也有重要影响。机械性能测试表明,Al/Fe2O3/NC复合纤维较NC具有更优异的力学性能,其弹性模量较NC纤维大幅提高,由71GPa提高至96GPa,增幅达35.21%。Pourmortazavi等[39]将具有高能量密度、热稳定性好、氮含量高和低感度特性的二氨基呋咱(DAF)与NC、Al粉和Fe2O3颗粒通过静电纺丝技术混纺得到直径约80nm的Al/Fe2O3/DAF/NC复合纤维(如图4(b)所示)。热分析结果表明,复合纤维中DAF通过分子间氢键与NC结合增加了NC自身的热稳定性,削弱了Al、Fe2O3等金属或金属氧化物对NC热解过程中O―N键断裂的影响,从而使得Al/Fe2O3/DAF/NC复合纤维的热分解温度由189℃(Al/Fe2O3 /NC)增加至197℃。热分解动力学进一步研究表明,Al/Fe2O3/DAF/NC具有更高的反应活化能和较小的反应速率常数,表现出较高的热稳定性。Al/Fe2O3/DAF/NC复合纤维较高的热稳定性对提高复合材料的存贮性能和热安定性是有益的。Lyu等[36]研究发现,将聚偏氟乙烯(PVDF)与CuO和Al粉通过静电纺丝技术复合后,CuO和Al颗粒均匀负载在PVDF纤维上,纳米颗粒间的团聚现象被显著弱化(如图4(c)所示),Al粉颗粒表面的氧化和预反应烧结现象被抑制,抗氧化能力得到显著改善和提高。热分解行为和点火性能研究表明,PVDF/CuO/Al复合纤维的能量密度、反应热和火焰传播速率明显提高。纺丝PVDF/CuO/Al纤维的反应热由2800J/g(Cu/Al)增至3771.5J/g,增幅达34.7%,火焰传播速率由0.09m/s(Al/CuO/PVDF:电喷雾法制备)增至0.84m/s。PVDF/CuO/Al复合纤维中具有较强抗氧化特性的PVDF在燃烧分解过程中既作为氧化剂与Al粉反应又作为燃料与CuO和Al2O3反应,对提高产物的能量和点火特性发挥了重要的作用。

研究表明,静电纺丝技术一方面能够有效抑制铝热剂型含能复合材料中纳米Al粉和金属氧化物颗粒的团聚现象,提高复合纤维燃烧过程中的传质和传热速率。另一方面,复合含能纤维材料中纳米Al粉被高分子聚合物包覆,能够显著增强存储过程中Al粉的抗氧化能力,提高其存贮和安全特性。

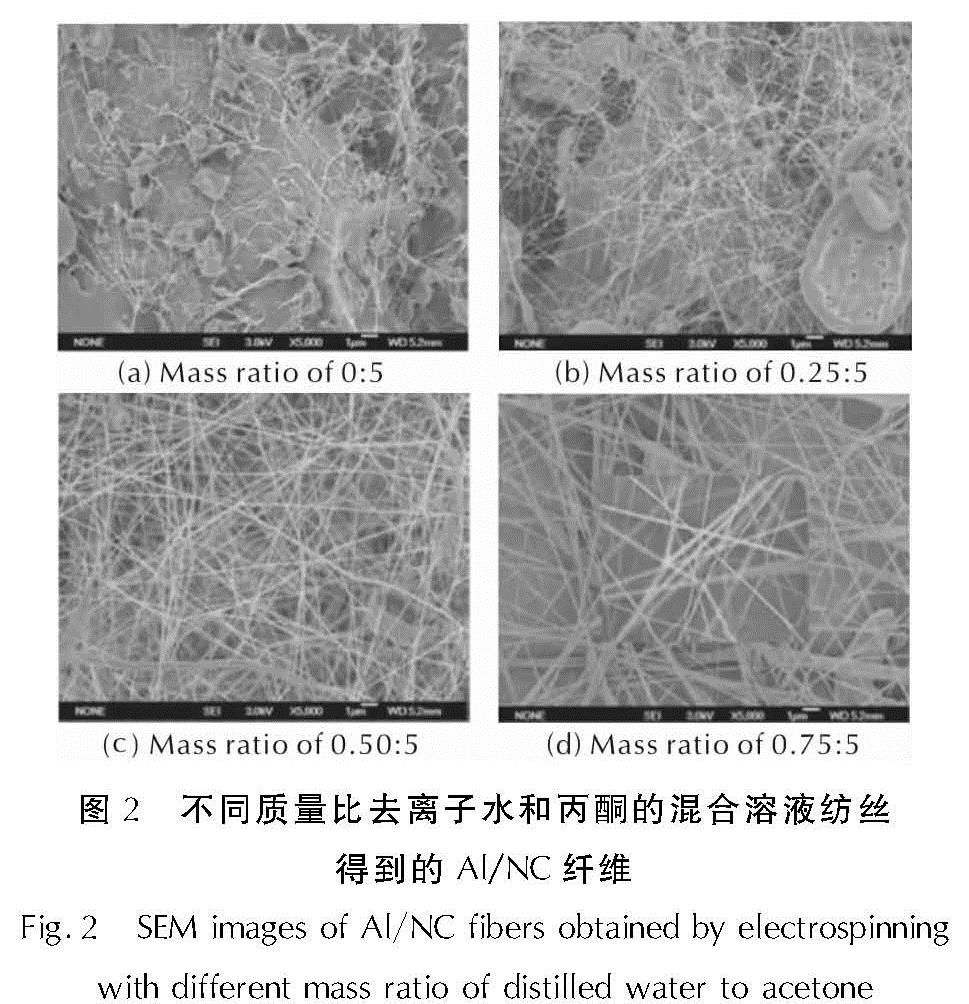

2.2 在单质含能材料和固体燃料纳米化中的应用NC是一种常用的含能材料,作为推进剂黏合剂时其形貌特征对推进剂的加工成型和力学性能存在显著影响。将传统棉球状的NC纤维纳米化可以显著增大NC纤维的比表面积,改善NC的燃烧性能、提高推进剂能量特性和力学性能。夏敏等[16]用丙酮/乙醇的混合溶液通过静电纺丝工艺得到了直径80nm的NC纳米纤维。热分析结果表明,纳米化后的NC纤维热分解性能显著改善,表观放热量较NC显著增至1835.80J/g。Sovizi等[40]研究发现NC纤维的尺寸显著影响其热稳定性和热分解性能,NC纳米化后,其热分解温度和表观活化能显著降低,微米NC纤维分解过程的活化能是纳米尺度NC纤维的1.5倍余。微米、纳米NC纤维的SEM照片如图5(a)和(b)所示,表2详细比较了微米、纳米NC的热分解行为及动力学参数。

表2 微米、纳米NC热分解行为和动力学参数比较

Table 2 Comparison of thermal behaviors and kinetic parameters of micron and nano NC将NC与成气性高、燃烧温度低、能量密度大的硝胺类化合物如HMX、RDX、CL-20等复合纳米化,可以进一步提高推进剂的能量特性。徐红梅等[41]将RDX和NC溶解在丙酮和N, N-二甲基甲酰胺(DMF)的混合溶剂中,通过静电纺丝工艺得到了RDX/NC纳米复合纤维(见图5(c)),并研究了其热分解性能和力学特性。热分析结果表明,RDX/NC纳米复合纤维的热分解温度较RDX、NC及RDX和NC的物理混合样均有降低,放热分解半峰宽变窄、热分解过程加剧。RDX/NC复合纤维热分解性能的提升归因于纤维基体中RDX和NC的紧密接触及较大的比表面积,其加快了反应过程的传热传质速率。力学性能实验表明,RDX/NC复合纤维的弹性模量由于存在氢键(NC结构中的―OH与RDX中的―NO2形成氢键)较NC纤维大幅提高,由47GPa提高至153GPa,增幅达3倍多。Li等[42]通过静电纺丝工艺将CL-20嵌入到聚丙烯腈(PAN)纤维膜中(见图5(d)),研究了CL-20/PAN纳米复合纤维膜的热分解行为和燃烧特性。结果表明,CL-20/PAN复合纤维较CL-20具有更高的热感度,PAN纤维使CL-20的起始分解温度和放热分解峰温分别降低约38℃和19℃。同时,PAN和CL-20的紧密接触使得CL-20/PAN放热速率显著增加。在点火和燃烧试验中,CL-20/PAN纤维表现出显著增强的燃烧特性,火焰亮度增强、燃烧更加充分。CL-20/PAN纤维改善的热分解和燃烧特性,能够很好地满足狭窄空间高点火能量的需求。

高热值的纳米金属粉作为燃料或燃速调节剂在含能材料中广泛使用,对提高推进剂燃速和比冲有显著的作用[1, 43]。谢龙等[17]通过静电纺丝技术制备了含纳米Al的NC复合含能纤维(见图6(a)),并通过扫描电镜观察发现在合适的工艺参数条件下,纳米Al粉颗粒均匀地分散在NC纤维中,纳米Al粉的团聚现象显著被抑制。将其应用于固体推进剂对抑制纳米Al粉颗粒预反应烧结、提高Al粉的燃烧效率是有益的。复合纤维集NC纤维良好的机械特性和Al粉高能量密度的特性于一体,显著提高了推进剂的力学性能和燃烧特性。Li等[44]通过静电纺丝技术得到直径均匀的硼(B)/NC复合纤维(见图6(b)),纳米B颗粒均匀地分散在NC纤维基体中,其团聚现象显著得到改善,复合纤维的热分解速率和反应深度较B和NC的物理混合物显著增强。燃烧实验表明,B/NC纤维的燃烧过程较物理混合样(B+NC)更为剧烈,火焰传播速率更快,火焰结构中有大量热亮球生成,燃烧效率更高,表现出显著增强的燃烧分解特性。

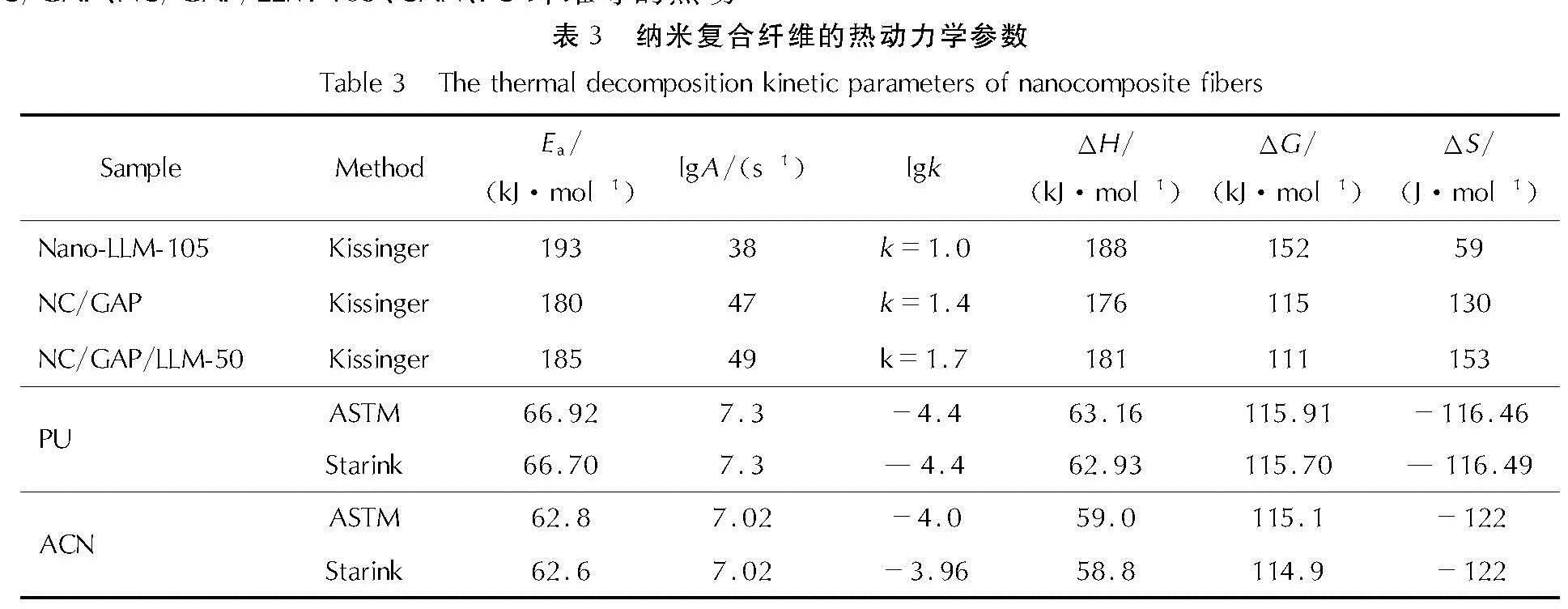

此外,静电纺丝技术也广泛应用于高能聚合物单体及混聚物纤维的制备和热行为研究。Luo等[45]研究发现,通过静电纺丝工艺制备的NC/GAP/LLM-105(2, 6-二氨基-3, 5-二硝基吡嗪-1-氧化物: ANPZO, 俗称LLM-105)纳米复合纤维(见图6(c)和(d))拥有较大的比表面积、较低的热分解温度、较高的分解速率、较大的比冲(Isp=2027N·s·kg-1)和较低的撞击感度(特性落高H50=78cm),表现出增强的能量特性、热分解特性和钝感特性,被视为一种理想的高能钝感含能复合材料。Pourmortazavi等[46]研究了叠氮脱氧纤维素硝酸酯(ACN)和聚氨酯(PU)纺丝纤维(见图6(e)和(f))的热行为,结果表明,ACN和PU纤维较其相应的块状材料具有更低的起始分解温度、更高的分解活化能和更好的热稳定性,作为含能黏结剂应用于固体推进配方中对含能材料的存贮和过程加工是有利的。表3列出了NC/GAP、NC/GAP/LLM-105、CAN、PU纤维等的热动力学行为参数。

静电纺丝技术是调控含能纤维组成、结构和实现推进剂等含能材料纳米化的一种有效方法。调节纺丝液前驱体溶液组成、控制静电纺丝过程工艺参数能够得到不同表面结构、大比表面积和长径比的功能化纳米复合含能纤维,满足不同武器装备的差异化性能需求。同时,含能材料纳米化在改善其燃烧特性、点火性能、能量特性、力学性能以及爆炸性能等方面表现出良好的潜在应用价值。最后,静电纺丝得到的微单元化纳米含能复合材料有望作为优异的能量源,应用于微纳米尺度含能器件等。

2.3 在爆炸物荧光检测材料中的应用高能爆炸物被广泛应用在大规模杀伤性武器中,在国际反恐和领土安全方面,爆炸物探测已成为研究的热点之一。无接触的荧光探测传感器由于传感单元多、灵敏度高、选择性好、荧光亮度高、响应时间短、光稳定性好、制备简单等特点,在爆炸物检测应用中受到了广泛关注[47-48]。Wang等[49]通过静电纺丝技术制备了芘/聚苯乙烯(PS)/四丁基六氟磷酸胺(TBAH)纳米荧光纤维膜(见图7(a)和(b)),并将其用于紫外光激发下超微量高能爆炸物蒸汽和埋藏炸药的裸眼检测。结果表明,芘/PS/TBAH纤维与缺电子的硝基高能爆炸物如TNT、RDX、HMX和PETN等之间具有较强的亲和力,复合纤维能够加速能量的远距离传输效率和光诱导电子的迁移率,快速实现荧光放大淬灭效应,具有检测极限低、选择性强的特性。芘/PS/TBAH新型纳米复合荧光纤维传感材料在埋藏炸药裸眼检测中表现出的良好应用性能,为大规模地雷探测和清除开辟了一种新方法。同时,其成本低廉、重复使用性好且可实现放大生产,具有广阔的应用前景。Sun等[50]研究表明,电纺芘/聚醚砜复合纤维膜(见图7(c))对水相中的硝基高能爆炸物如苦味酸(PA)、2, 4, 6-三硝基甲苯(TNT)、2, 4-二硝基甲苯(DNT)以及RDX,具有很高的检测灵敏度,其高灵敏度检测特性归属于荧光淬灭过程中能量和光诱导电子在纤维基体的快速转移。此外,纤维膜的选择性研究表明,纳米荧光纤维荧光发射强度受水相中常见干扰物的影响较弱,对硝基高能爆炸物表现出很高的选择性。同时,静电纺丝制备的芘/聚醚砜传感器膜用去离子水简单洗涤后能够重复使用,具有较高的循环使用特性。复合纤维膜的高灵敏度检测特性、高选择性、经济、廉价和可循环使用特性,在水相爆炸物的高效检测中具有很好的应用前景。

图7 电纺芘/PS/TBAH和芘/聚醚砜纤维的SEM照片

Fig.7 SEM images of electrospinning Pyrene/PS/TBAH and Pyrene/polyethersulfone fibers荧光检测的机理可以概述为荧光分子中激发态的电子与缺电子的化合物受体结合,通过光诱导电子转移(PET)、Forster共振能量转移(FRET)以及内滤效应(IFE)等光物理过程阻断电子在荧光分子中的流动、改变荧光信号形成荧光淬灭,从而达到爆炸物检测的目的[49, 51]。电纺纳米复合纤维由于独特的结构特性如较大的比表面积和多孔结构等,有利于荧光检测过程中爆炸物分子的快速扩散及其与荧光基团的充分接触,从而实现电子的快速转移和爆炸物的痕量检测。电纺纳米复合纤维由于检测灵敏度高、选择性强、经济环保,在含能爆炸物检测中表现出极好的应用前景。

3 结束语

静电纺丝技术是一种工艺简单、操作便捷、快速高效的可连续制备纳米复合纤维材料的新方法,利用静电纺丝技术不仅可以构筑包括聚合物、无机物、聚合物/无机物复合材料等多种纳米材料,而且通过工艺参数的调节可以实现材料表面结构、形貌和功能的差异化调控,满足不同领域的应用需求。在含能材料领域,通过静电纺丝技术制备得到的微纳米复合含能纤维可有效改善含能材料的能量特性、燃烧性能和力学性能,从而提高含能材料的综合应用性能,呈现出极大的潜在应用价值和广阔的应用前景。

目前,静电纺丝技术在含能材料中的应用研究尚处于探索阶段,相关报道主要集中在纳米铝热剂型含能复合纤维、单质含能材料和固体燃料纳米化的制备及热分解行为研究等方面,对材料在推进剂配方中的应用研究及纤维形成过程和机理的探索还需要继续深入。此外,静电纺丝技术在燃烧催化剂、含能黏结剂及其他多组分功能化纳米复合含能纤维等方面鲜有研究报道。利用静电纺丝纤维特殊的结构特性和力学增强性能研究不同形态、结构和组成的催化剂材料的催化性能及微单元化的含能材料的力学性能、燃烧和分解特性,提高固体推进剂综合性能也是必要的。最后,对含能纺丝纤维尺寸、形貌结构和性能的精细化调控以及推动纺丝技术在推进剂、火炸药等领域的规模化制备和应用研究也是亟需解决的重要课题。

静电纺丝技术作为一种日趋成熟的纳米复合材料制备工艺,建议在今后的研究工作中可结合静电纺丝设备特性及过程工艺操作参数,进一步研究制备更多种类聚合物纳米复合材料、聚合物/无机物复合材料及无机物纳米材料,并通过设备和工艺参数优化提高效率和产率,实现复合材料的规模化制备和应用。在固体推进剂领域,静电纺丝技术这一独特的工艺特性为实现纳米复合含能材料的微单元化和微纳米含能器件的小尺度装药提供了理论和实验基础,通过静电纺丝技术实现推进剂等含能材料的微单元化是未来一个重要的研究课题。

- [1] 赵凤起, 高洪旭, 仪建华, 等. 推进剂技术研究[M]. 西安: 西北工业大学出版社,2017.

- [2]胡向明, 黄振亚, 解德富, 等. 硝化纤维素含氮量对发射药力学性能的影响[J]. 火炸药学报,2019, 42(3): 308-311.

- [3]黄开金. 纳米材料的制备及应用[M]. 北京: 冶金工业出版社, 2009.

- [4]ZHANG D, KARKI A B, RUTMAND, et al. Electrospun polyacrylonitrile nanocomposite fibers reinforced with Fe3O4 nanoparticles: Fabrication and property analysis[J]. Polymer, 2009, 50: 4189-4198.

- [5]RAMAKRISHNA S, FUJIHARA K, TEO W E, et al. An introduction to electrospinning and nanofibers[M]. Singapore: World Scientific, 2005.

- [6]刘朝军, 刘俊杰, 丁伊可, 等. 静电纺丝法制备高效空气过滤材料的研究进展[J]. 纺织学报,2019, 40(6): 134-142.

- [7]CHU X F, GAN Z Q, BAI L S, et al. Acetone-sensing properties of ZnFe2O4 nanofibers prepared via electrospinning method[J]. Rare Metal Materials and Engineering, 2019, 48(5): 1371-1379.

- [8]HE Y, LIU Y G. Direct fabrication of highly porous graphene/TiO2 composite nanofibers by electrospinning for photocatalytic application[J]. Journal of Central South University, 2018, 25(9): 2182-2189.

- [9]刘照伟, 汤玉斐, 赵康. 静电纺丝制备多孔纳米纤维的研究进展[J]. 中国材料进展, 2018, 37(6): 410-427.

- [10]LI D, XIA Y N. Electrospinning of nanofibers: reinventing the wheel? [J]. Advanced Materials, 2004, 16(14): 1151-1170.

- [11]MCKEEM G, WILKES G L, COLBY R H, et al. Correlations of solution rheology with electrospun fiber formation of linear and branched polyesters[J]. Macromolecules, 2004, 37(5): 1760-1767.

- [12]THERON S A, ZUSSMAN E, YARIN A L. Experimental investigation of the governing parameters in the electrospinning of polymer solutions[J]. Polymer, 2004, 45(6): 2017-2030.

- [13]SON W K, YOUKJ H, LEE T S, et al. The effects of solution properties and polyelectrolyte on electrospinning of ultrafine poly(ethylene oxide)fibers[J]. Polymer, 2004, 45(9): 2959-2966.

- [14]ZAAROUR B, ZHANG W X, ZHU L, et al. Maneuvering surface structures of polyvinylidene fluoride nanofibers by controlling solvent systems and polymer concentration[J]. Textile Research Journal, 2019, 89(12): 2406-2422.

- [15]KOF K, WAN Y Q. Introduction to nanofiber materials[M]. Cambridge: Cambridge University Press, 2014.

- [16]夏敏, 罗运军, 华毅龙. 纳米消化纤维素的制备及性能表征[J]. 含能材料, 2012, 20(2): 167-171.

- [17]谢龙, 邵自强, 王文俊, 等. 含纳米铝粉的纳米NC纤维的制备[J]. 火炸药学报, 2011, 34(2): 77-79.

- [18]王艳芝. 静电纺丝技术发展简史及应用[J]. 合成纤维工业, 2018, 41(4): 52-57.

- [19]FORMHALS A. Method and apparatus for the production of fibers: US, 2123992 [P]. 1938.

- [20]吴元强, 许宁, 陆振乾,等. 静电纺丝设备的研究进展[J]. 合成纤维工业,2018, 41(6): 48-53.

- [21]MOHAMMAD M, SALAR Z. Review for application of electrospinning and electrospun nanofibers technology in textile industry[J]. Journal of Nanostructure in Chemistry, 2016, 6(3): 207-213.

- [22]JU J G, KANG W M, LI L, et al. Preparation of poly(tetrafluoroethylene)nanofiber film by electro-blown spinning method[J]. Materials Letters, 2016, 171(15):236-239.

- [23]ZHANG H T, WANG Q, CHEN Z Y, et al. Dynamics and feedback control of electrospinning process[J]. IEEE Transactions on Control Systems Technology, 2017, 25(2): 611-618.

- [24]杨豆,张卫波,赵倩芸,等. 纺丝液性质对静电纺丝的影响研究进展[J]. 精细与专用化学品, 2017, 25(5): 50-53.

- [25]XIE L, SHAO Z Q, WANG W J, et al. Preparation of AlNPs/NC composite nanofibers by electrospinning[J]. Integrated Ferroelectrics, 2011, 127: 184-192.

- [26]GUPTA P, ELKINS C, LONG T E, et al. Electrospinning of linear homopolymers of poly(methylmethacrylate):exploring relationships between fiber formation, viscosity, molecular weight and concentration in a good solvent[J]. Polymer, 2005, 46(13): 4799-4810.

- [27]KOSKI A, YIM K, SHIVKUMAR S. Effect of molecular weight on fibrous PVA produced by electrospinning[J]. Materials Letters, 2004, 58(3/4): 493-497.

- [28]喻祺, 邱志明,程慰,等. 离子液体对静电纺丝成型及电纺纤维形貌的影响[J]. 材料导报A:综述篇,2011, 25(11): 24-28.

- [29]冯燕,孙润军,刘呈坤. 海藻酸钠/聚乙烯醇/银复合纤维的静电纺丝[J]. 合成纤维, 2011, 40(12): 13-17.

- [30]傅杰财. 静电纺丝中形貌控制及其应用[D]. 兰州:兰州大学,2014.

- [31]LI X D, GAO C T, WANG J T, et al. TiO2 films with rich bulk oxygen vacancies prepared by electrospinning for dye-sensitized solar cells[J]. Journal of Power Sources, 2012, 214: 244-250.

- [32]RABOLT J F, LEE K H, GIVENS S R. Method of solution preparation of polyolefin class polymers for electrospinning processing include: US, 083983B2[P]. 2011.

- [33]YAN S, JIAN G Q, ZACHARIAH M R. Electrospun nanofiber-based thermite textiles and their reactive properties[J]. Applied Materials & Interfaces, 2012, 4: 6432-6435.

- [34]TILLOTSON T M, GASH A E, SIMPSON R L, et al. Nanostructured energetic materials using sol-gel methodologies[J]. Journal of Non-crystalline Solids, 2001, 285: 338-345.

- [35]安亭, 赵凤起, 裴庆, 等. 超级铝热剂的制备、表征及其燃烧催化作用[J]. 无机化学学报, 2011, 27(2): 231-238.

- [36]LYU J Y, CHEN S W, HE W, et al. Fabrication of high-performance graphene oxide doped PVDF/CuO/Al nanocomposites via electrospinning[J]. Chemical Engineering Journal, 2019, 368: 129-137.

- [37]MARTIROSYAN K S. Nanoenergetic gas-generators: principles and applications[J]. Journal of Materials Chemistry, 2011, 21: 9400-9405.

- [38]LI R, XU H M, HU H L, et al. Microstructure Al/Fe2O3/nitrocellulose energetic fibers realized by electrospinning[J]. Journal of Energetic Materials, 2014, 32(1): 50-59.

- [39]POURMORTAZAVI S M, KOHSARI I, ZANDAVAR H, et al. Electrospinning and thermal characterization of nitrocellulose nanofibers containing a composite of diaminofurazan, aluminum nano-powder and iron oxide nanoparticles[J]. Cellulose, 2019, 26(7): 4405-4415.

- [40]SOVIZI M R, HAJIMIRSADEGHI S S, NADERIZADEH B. Effect of particle size on thermal decomposition of nitrocellulose[J]. Journal of Hazardous Materials, 2009, 168: 1134-1139.

- [41]徐红梅,李瑞,蒋小军,等. RDX/NC纳米复合纤维的制备及性能[J]. 火炸药学报, 2012, 35(6): 28-31.

- [42]LI Y R, REN H, JIAO Q J. Preparation of new structure energetic composite of HNIW implanted into microporous fibosa[J]. Chinese Journal of Energetic Materials, 2017, 25(4): 309-314.

- [43]裴红波,钟斌,李星瀚,等. RDX基含铝炸药圆筒试验及状态方程研究[J].火炸药学报, 2019, 42(4): 403-409.

- [44]LI Y C, YANG H T, HONG Y, et al. Electrospun nanofiber-based nanoboron/nitrocellulose composite and their reactive properties[J]. Journal of Thermal Analysis and Calorimetry, 2017, 130(2): 1063-1068.

- [45]LUOT T, WANG Y, HUANG H, et al. An electrospun preparation of the NC/GAP/Nano-LLM-105 nanofiber and its properties[J]. Nanomaterials, 2019, 9: 854-869.

- [46] POURMORTAZAVIS M, SADRI M, NASRABADI M R, et al. Thermal decomposition kinetics of electrospun azidodeoxy cellulose nitrate and polyurethane nanofibers [J]. Journal of Thermal Analysis and Calorimetry, 2015, 119: 281-290.

- [47]吴晓甫, 童辉, 王利祥. 爆炸物检测用荧光聚合物材料[J]. 化学进展, 2019, 31(11): 1509-1527.

- [48]MINEI P, PUCCI A. Fluorescent vapochromism in synthetic polymers[J]. Polymer International, 2016, 65: 609-620.

- [49]WANG Y, ANTHONY L A, DING Y, et al. Novel signal-amplifying fluorescent nanofibers for naked-eye-based ultrasensitive detection of buried explosives and explosive vapors[J]. Advanced Functional Materials, 2012, 22: 3547-3555.

- [50]SUNX C, LIU Y X, SHAW G, et al. Fundamental study of electrospun pyrene-polyethersulfone nanofibers using mixed solvents for sensitive and selective explosives detection in aqueous solution[J]. ACS Applied Materials & Interfaces, 2015, 7: 13189-13197.

- [51]刘挺, 王先明, 吴钊峰. 硫化钼量子点在爆炸物荧光检测中的作用[J]. 新疆师范大学学报, 2019, 38(2): 27-32.