作者简介:王英红(1972-),女,副教授,从事推进剂燃烧、工艺、性能预估及测试研究。E-mail: snow@nwpu.edu.cn

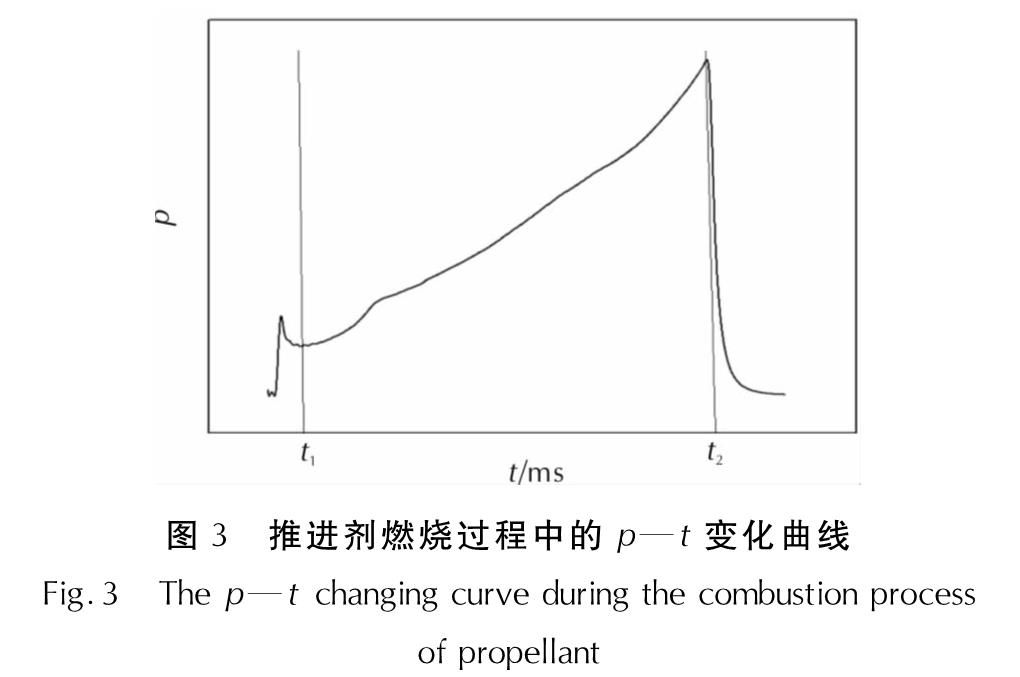

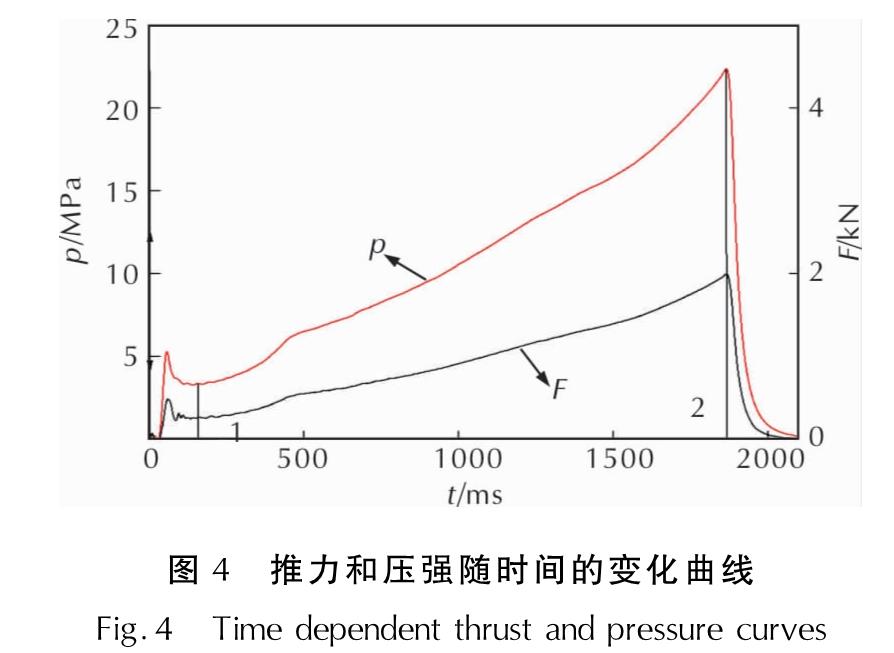

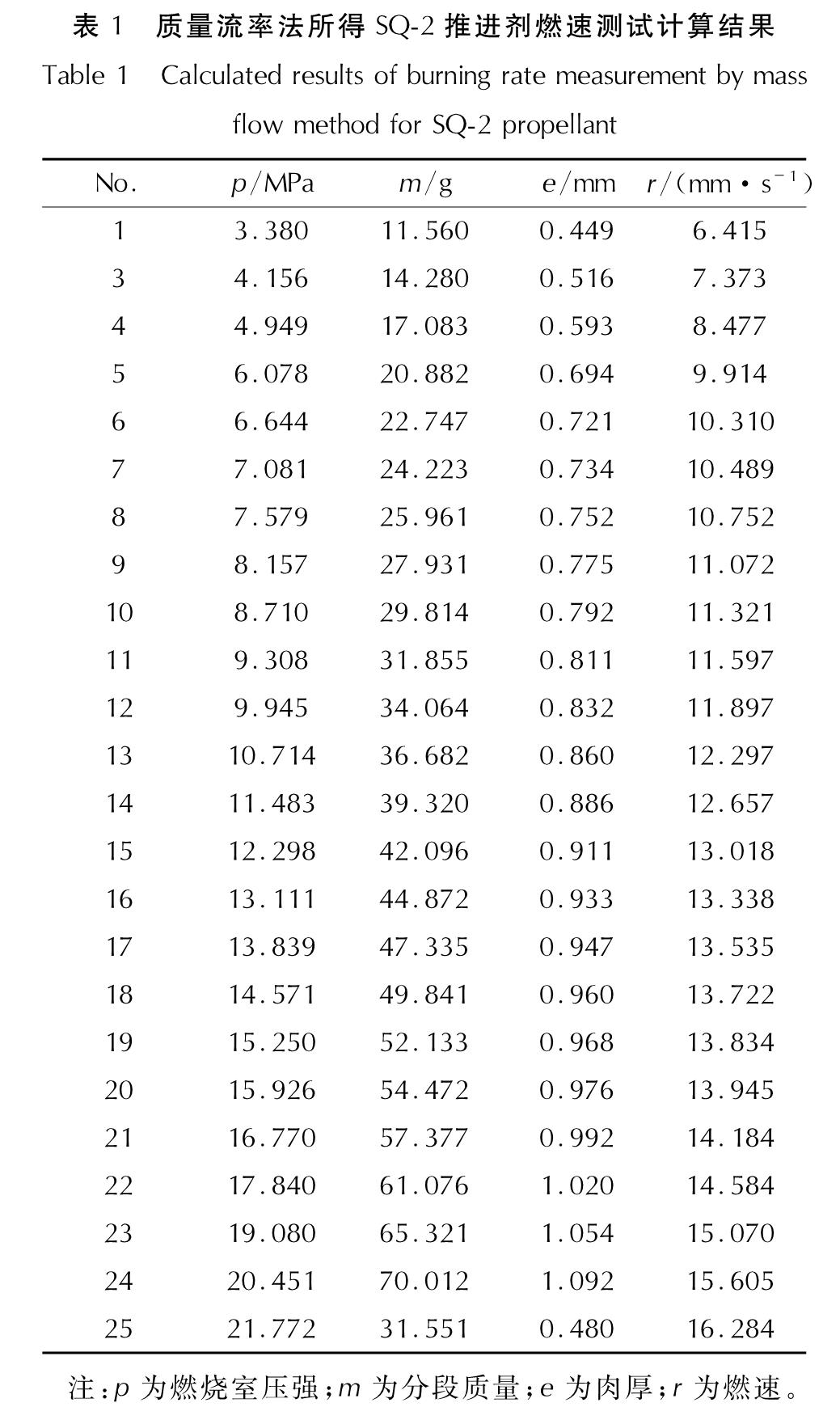

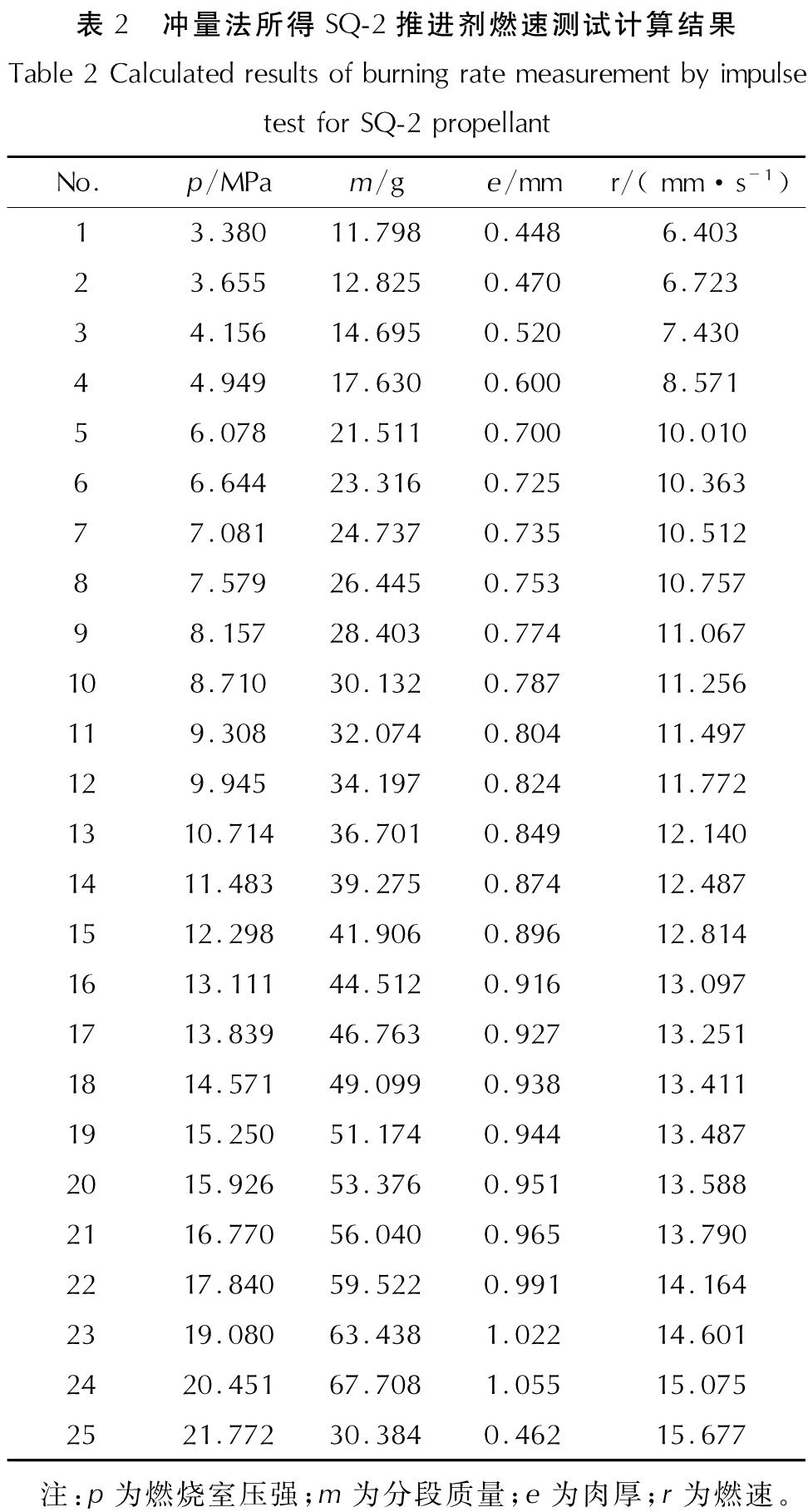

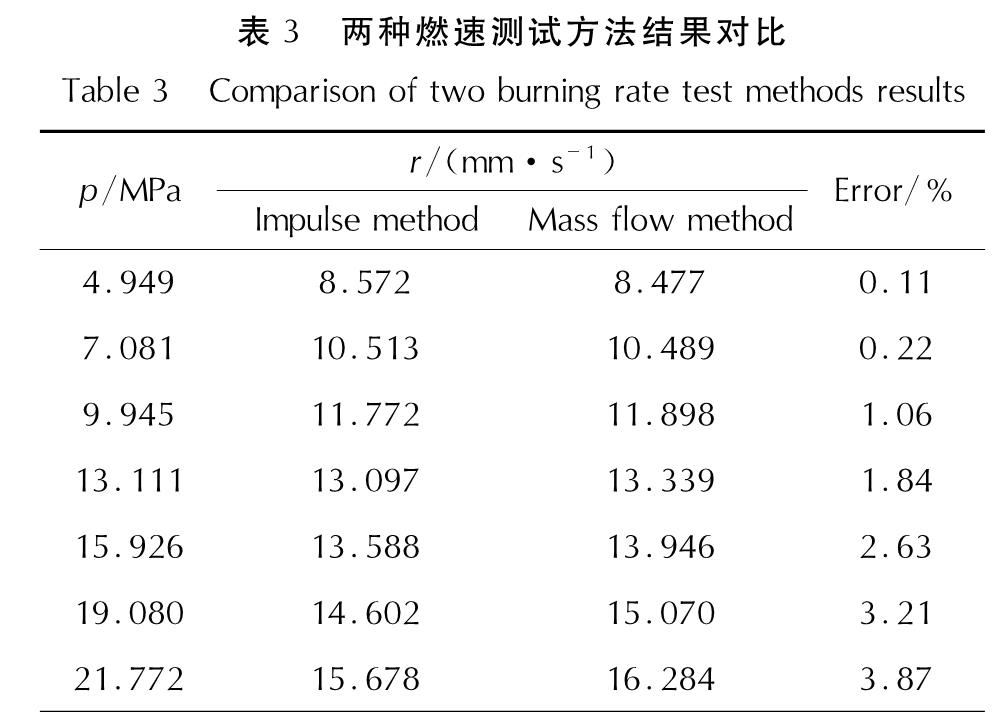

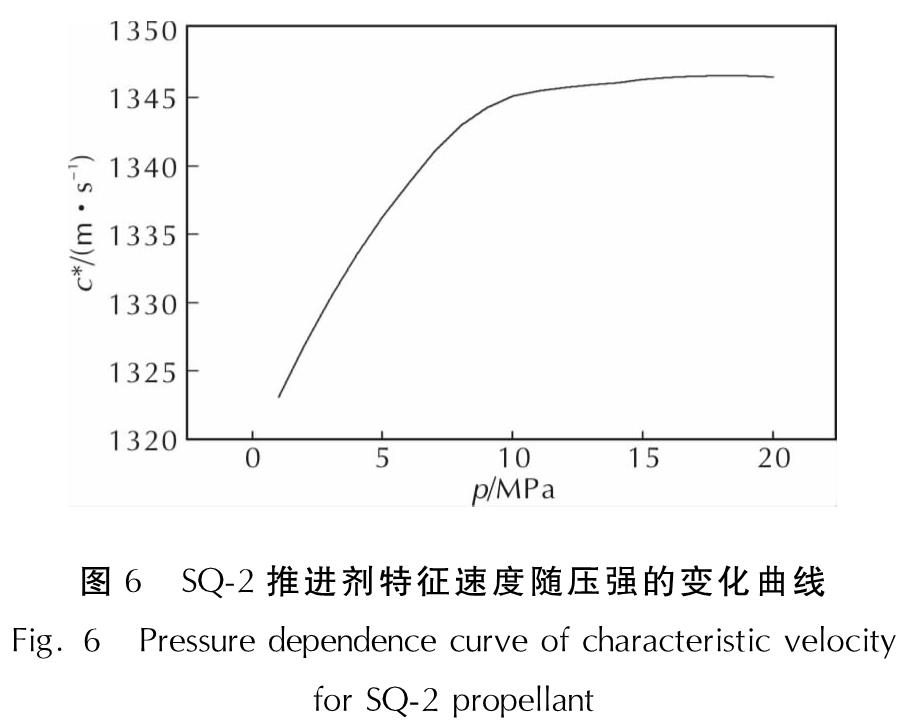

为了实现单次发动机试验测得多个压强条件下推进剂的燃速,提出了一种固体推进剂动态燃速测试方法——质量流率法。该法以质量流率计算公式为依据,通过处理推进剂燃烧过程中随时间递增的压强曲线,计算得到发动机工作全过程中不同时刻对应压强下的燃速值; 对比了通过质量流率法与冲量法处理得到的双铅-2(SQ-2)推进剂燃速结果; 分析了特征速度和喷管喉径变化对质量流率法燃速测试结果的影响。结果 表明,两种方法得到的燃速结果随压强变化趋势完全一致; 当压强为9.945MPa时,两种方法的误差为1.06%; 当压强为22MPa时,误差为3.87%。造成质量流率法与冲量法燃速结果之间差异的主要原因为喷管喉径实际尺寸的变化。

In order to obtain the burning rate of propellant under multiple pressures in a single engine test, the dynamic burning rate test method of solid propellant-mass flow rate method is proposed. This method is based on the mass flow rate calculated formula. By processing the pressure curve which increases with time in the combustion process of propellant, the burning rates at different times corresponding to the pressure during the entire engine operation were calculated. The burning rate results of double lead-2(SQ-2)propellant by the mass flow rate method and the impulse method were compared. The effects of characteristic velocity and nozzle throat diameter changes on the burning rate rusults by the mass flow rate method were analyzed. The results show that the burning rate results obtained by the two methods are consistent with each other. When the pressure is 9.945MPa, the error is 1.06%, and when the pressure is 22MPa, the error is 3.87%. The main reason for the difference between the mass flow rate method and the impulse method is the change of nozzle throat diameter.