作者简介:邵珠格(1995-),男,硕士研究生,从事炸药损伤表征研究。E-mail: shaozge@163.com 通信作者:吴艳青(1974-),女,博士,教授,从事炸药点火机理研究。E-mail: wuyqing@bit.edu.cn

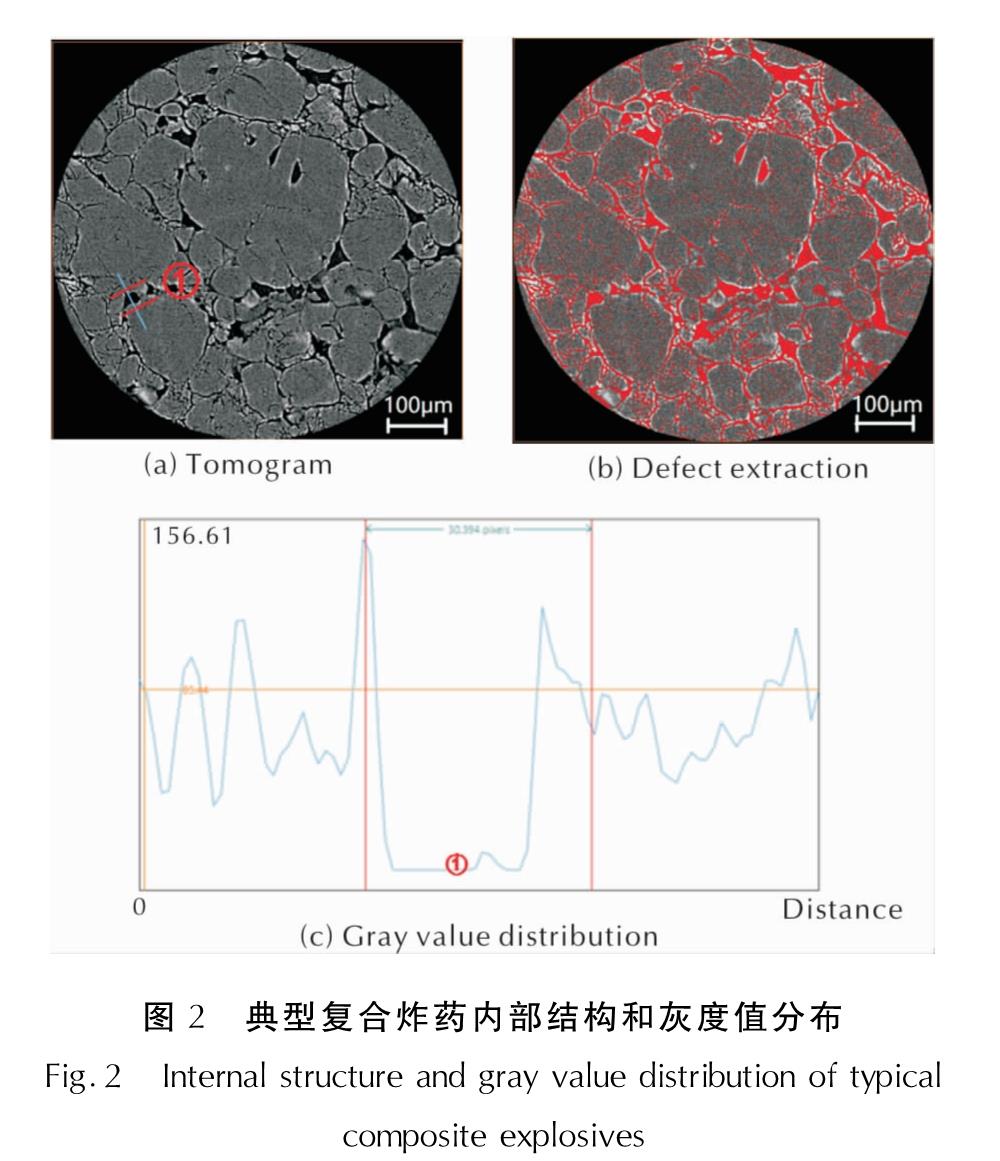

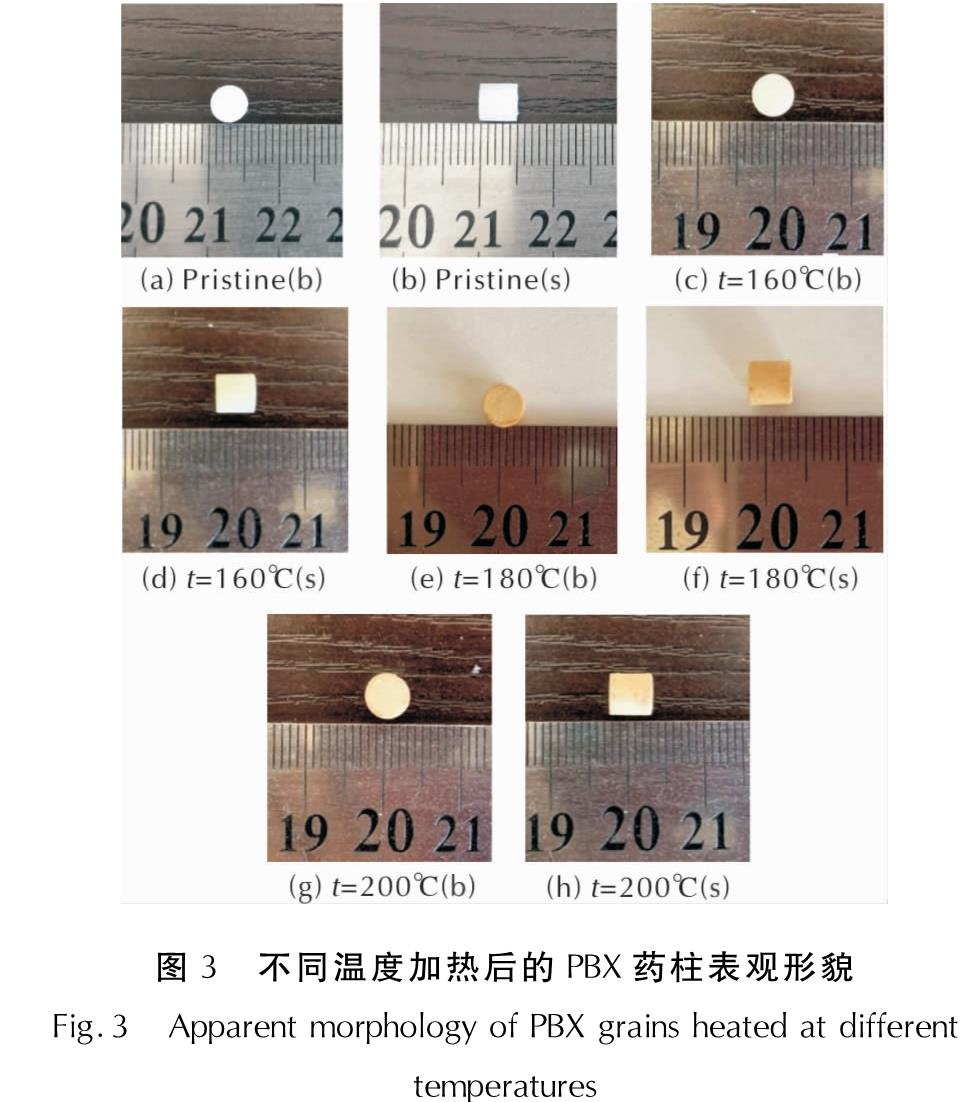

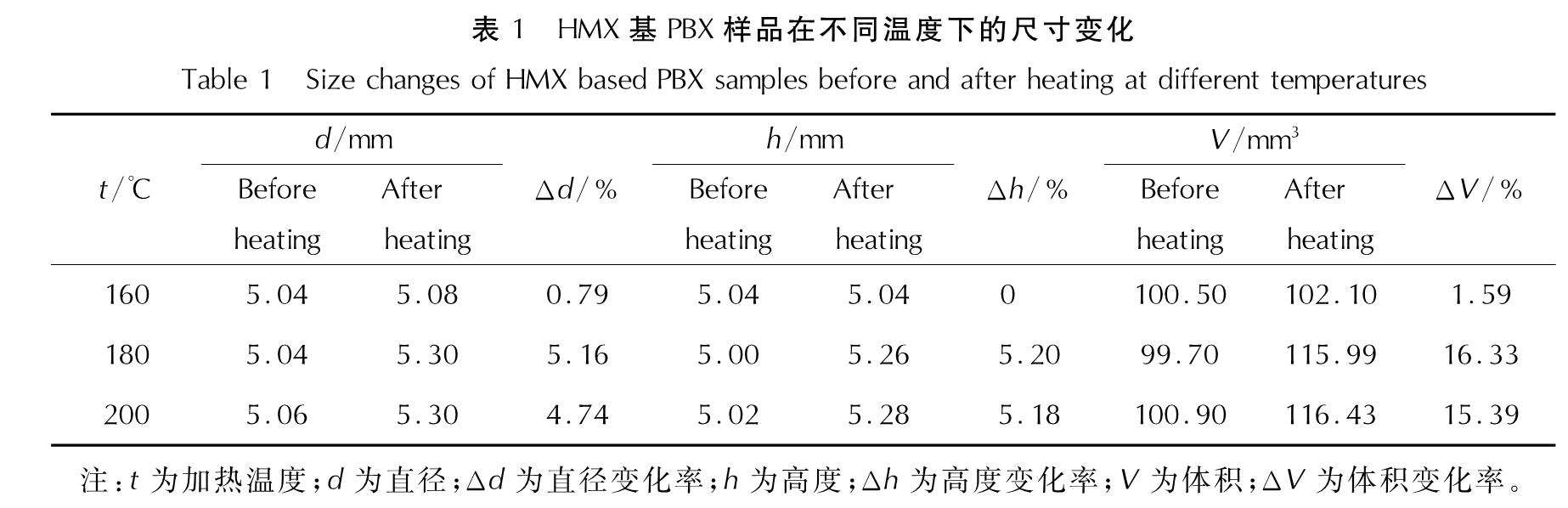

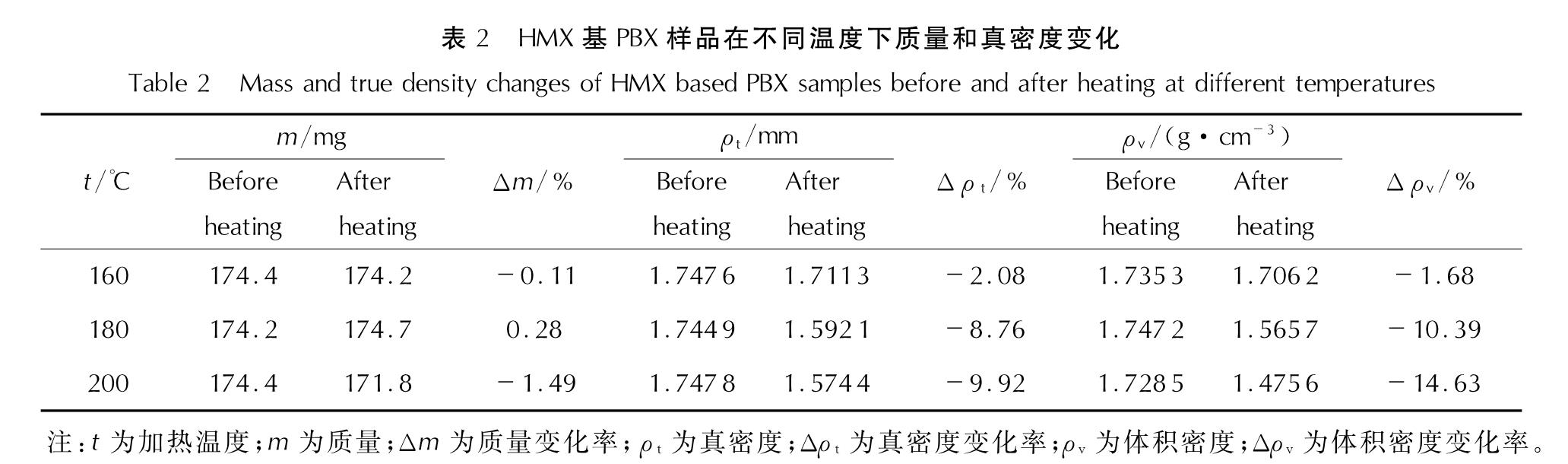

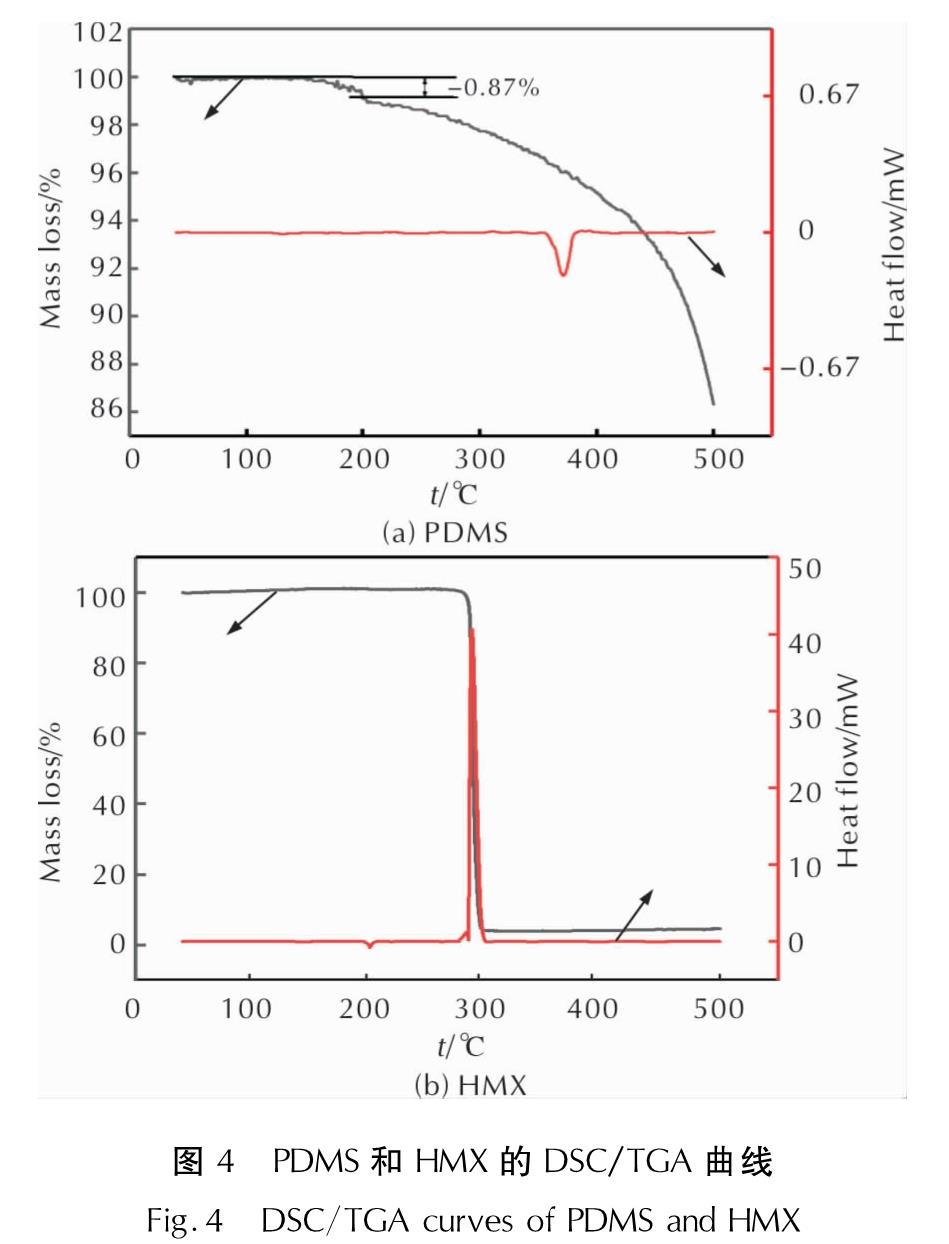

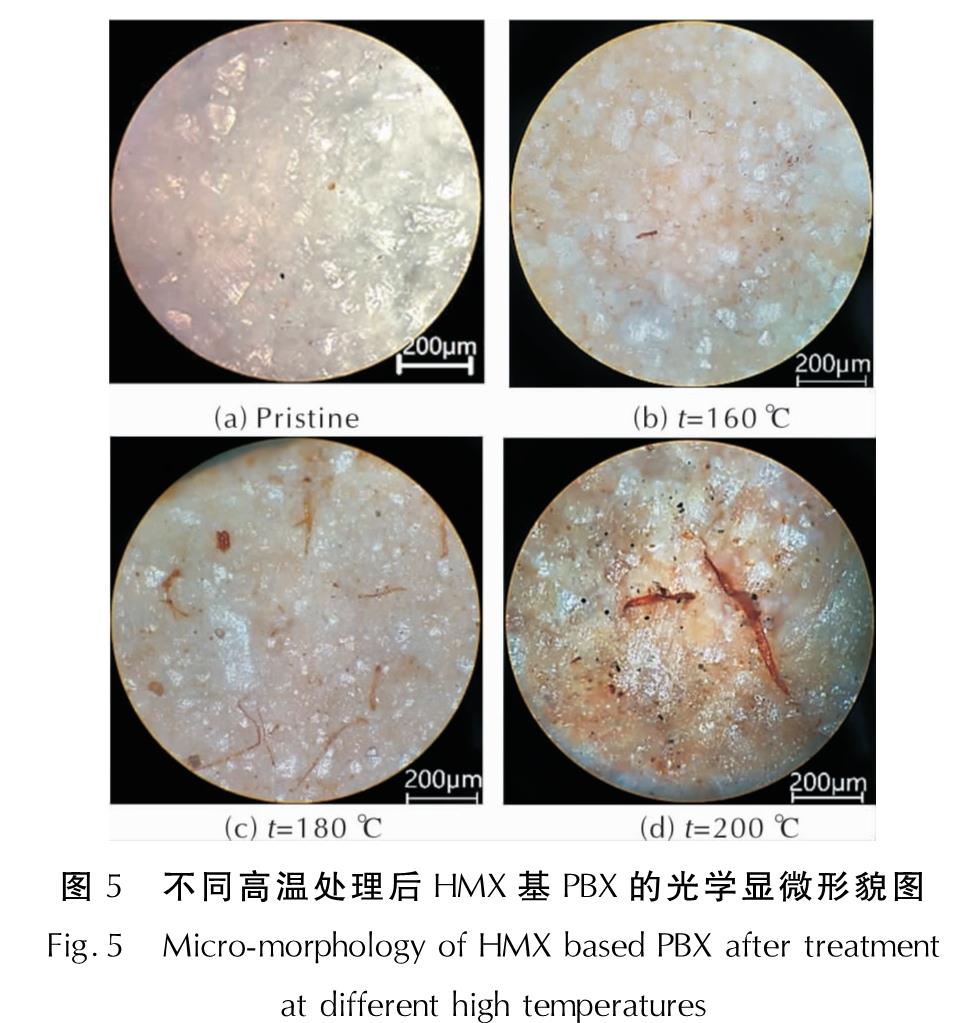

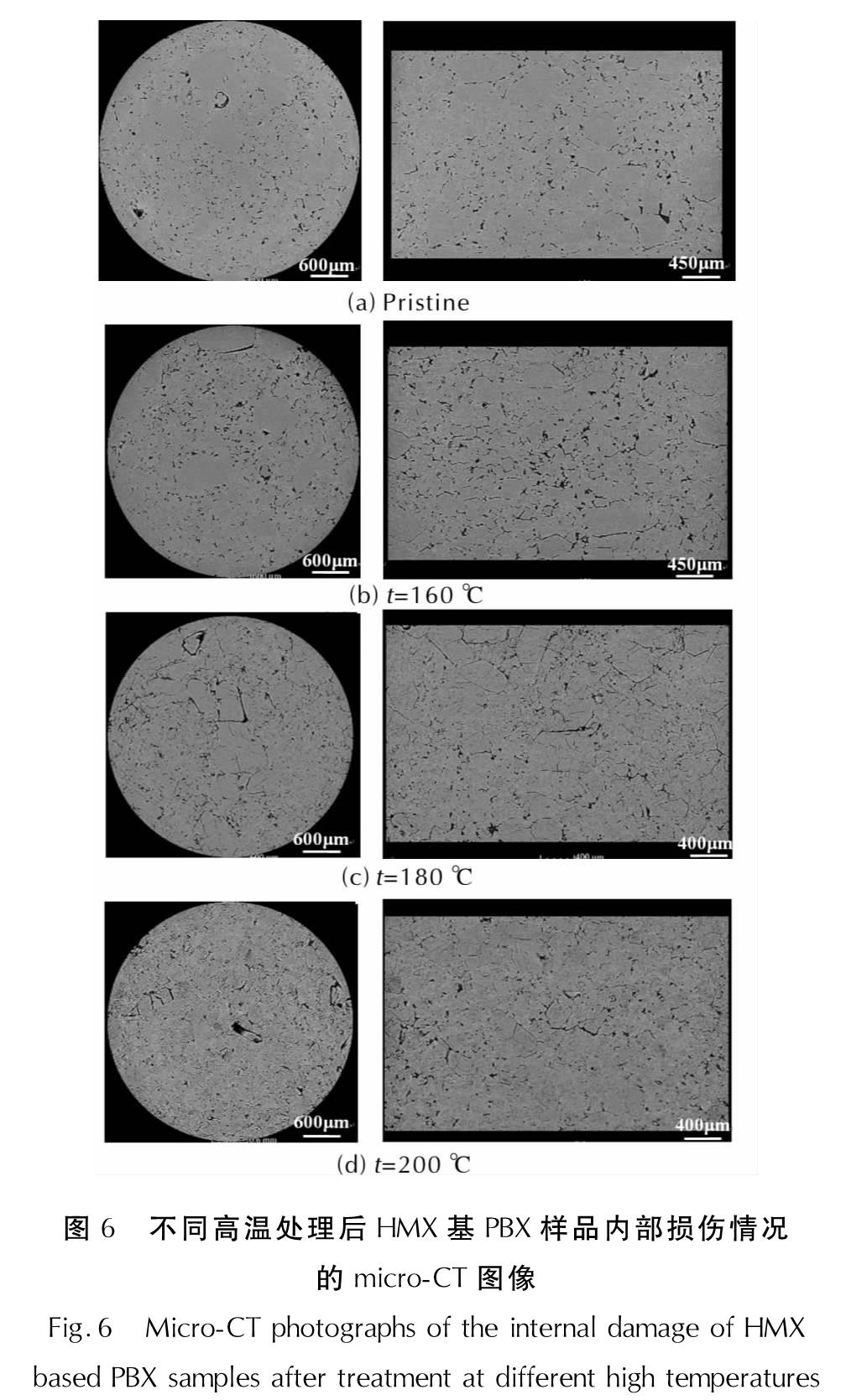

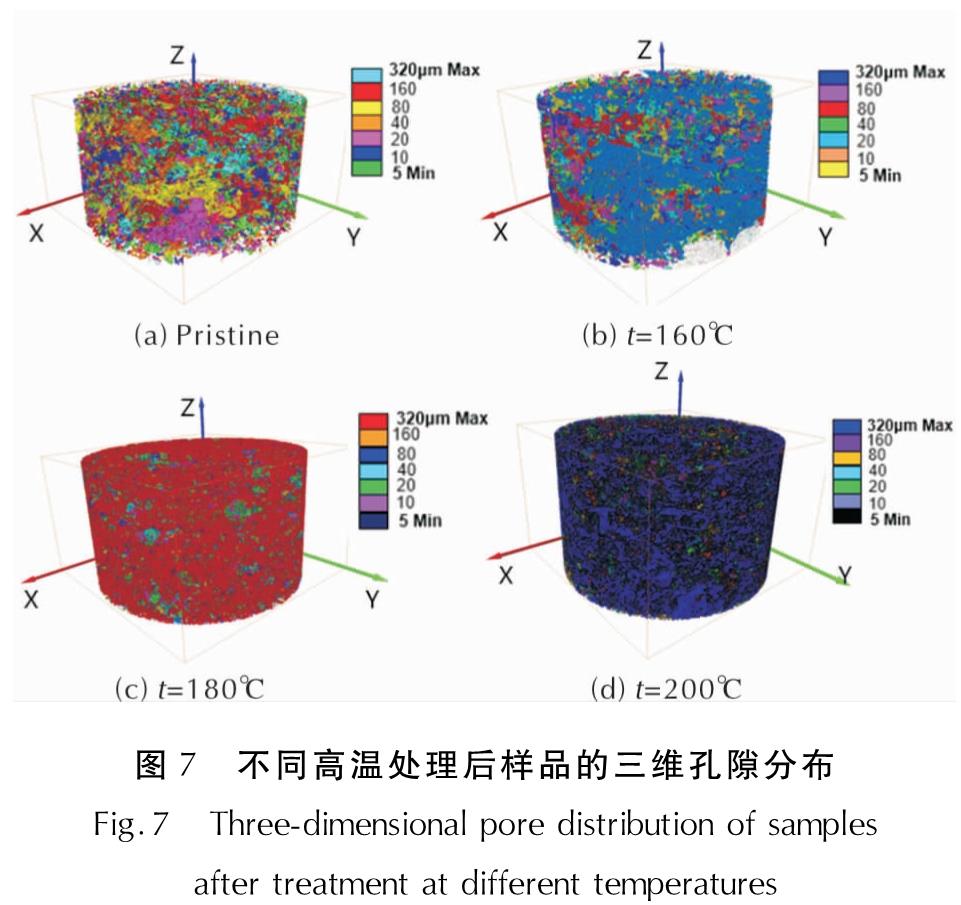

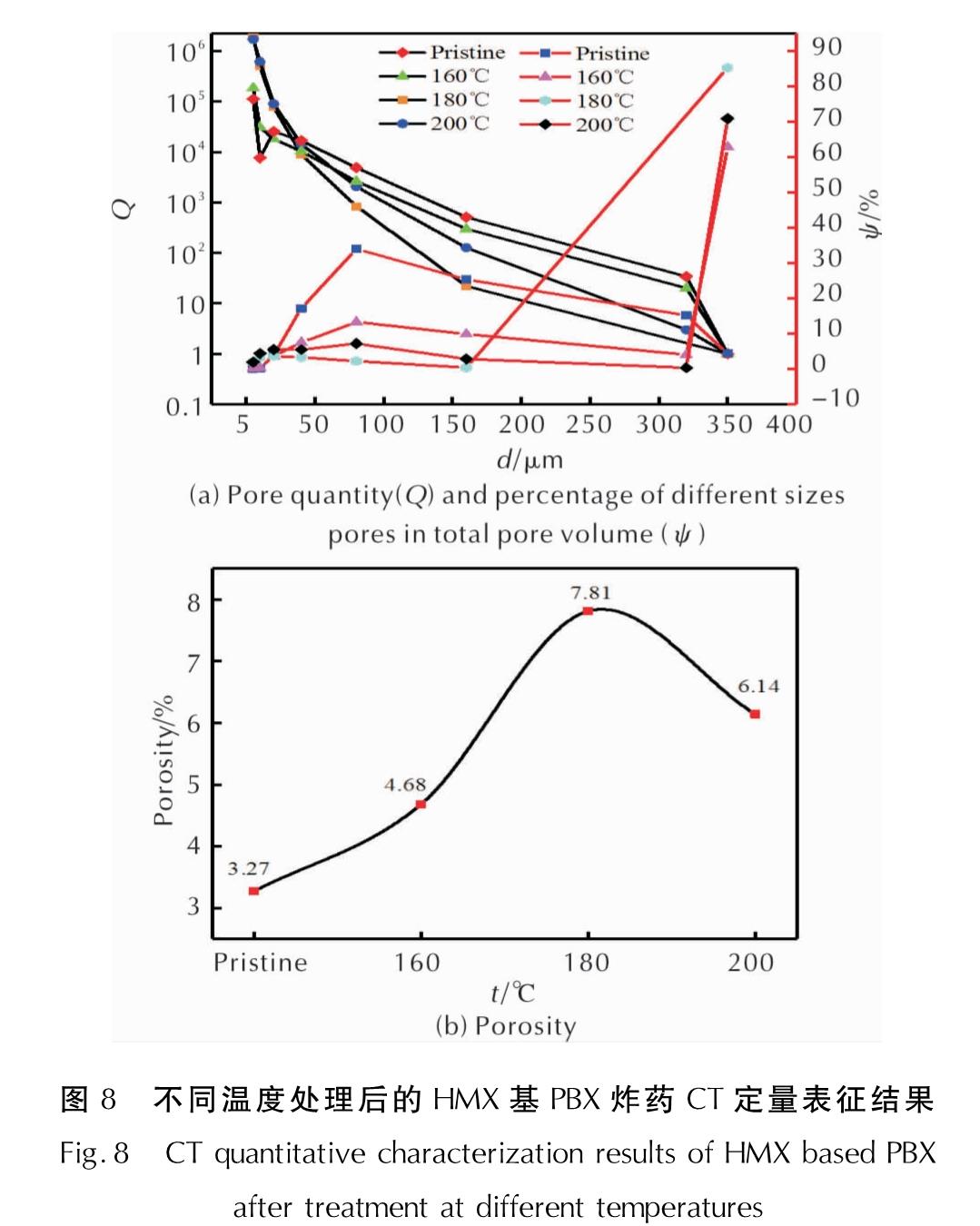

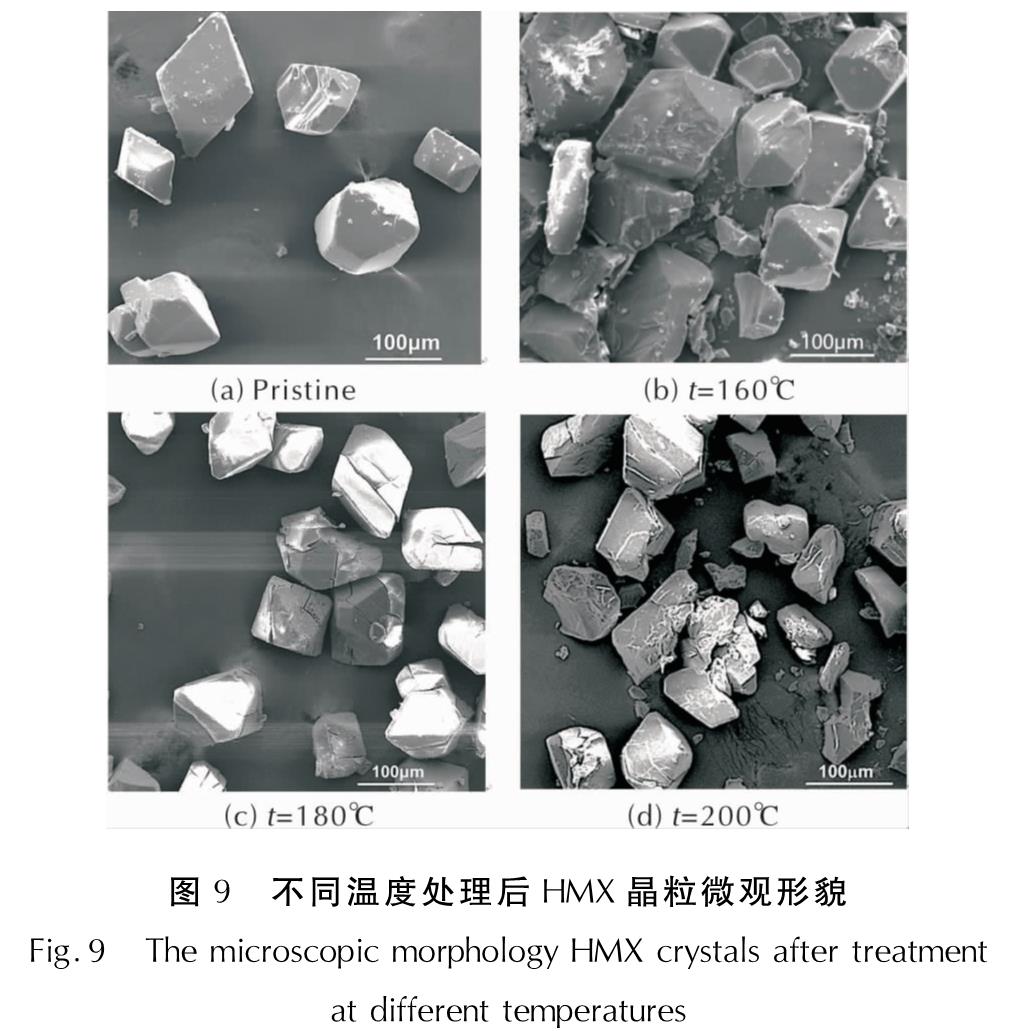

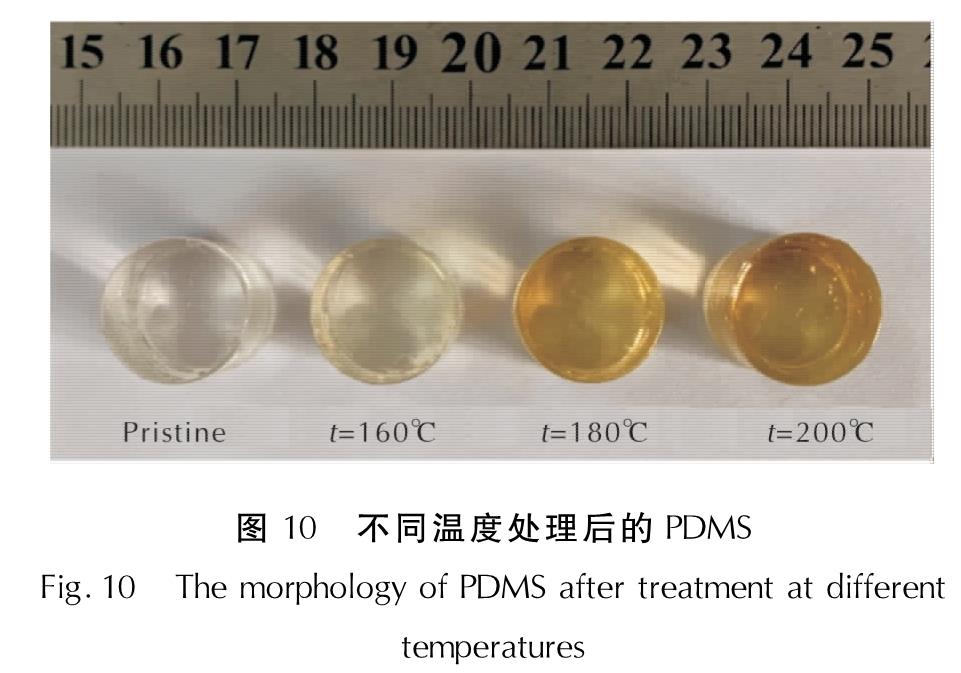

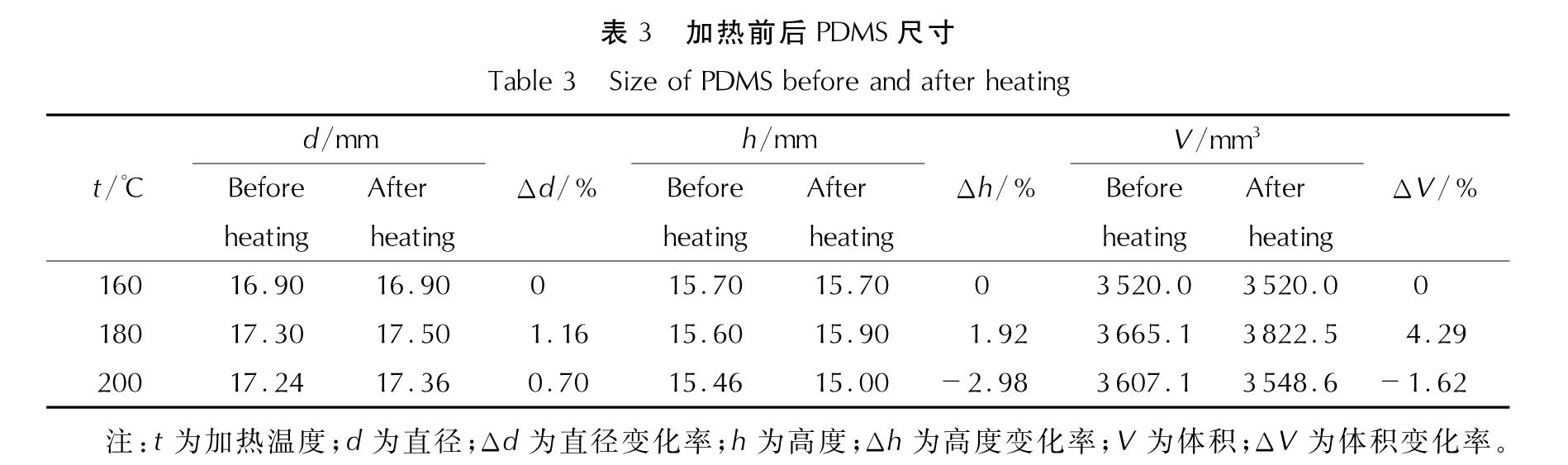

为研究环四亚甲基四硝胺(HMX)基高聚物黏结炸药(PBX)在高强度热载荷(室温~200℃,10h)作用下的热损伤行为,使用微米计算机断层扫描技术(micro-CT)定量表征了试验前后HMX基PBX的内部微米级孔隙变化,结合样品尺寸、质量、真密度和微观形貌的变化分析了热载荷对HMX基PBX的损伤情况。结果 表明,在160℃时,样品体积、质量和真密度无显著变化; 经过180℃处理后,样品发生了不可逆的体积膨胀,质量未发生变化,真密度降低8.76%; 200℃处理后,由于质量降低、体积膨胀,样品表面出现孔隙和裂纹导致样品真密度降低9.92%; 根据细观观测和统计计算,样品孔隙率随试验温度升高呈现先升高后降低的趋势,在180℃时最高为7.81%,200℃时又呈现下降趋势; 180℃时HMX晶粒发生相变,产生的大量微裂纹和颗粒之间脱粘增大了PBX的孔隙率; 200℃时,HMX颗粒细化填充部分空隙,导致孔隙率较180℃时降低,但黏结剂未发生熔化,对孔隙率的变化影响不大。

To study the thermal damage behavior of cyclotetramethylenete-tranitramine(HMX)based polymer bonded explosive(PBX)undergoing high-intensity thermal insult(room temperature to 200℃, 10h), micron-scale computed tomography(micro-CT)was used to quantitatively characterize the changes of the micron-scale porosity of HMX based PBX before and after heating. Combined with the changes of sample size, mass, true density and micro-morphology, the thermal damage of HMX based PBX was analyzed.The results show that the sample volume, mass and true density do not change obviously at 160℃. The volume expansion of the sample is observed to be irreversible after treatment at 180℃, and the true density decreases by 8.75%. However, the mass does not change. After treatment at 200℃, the true density reduces up to 9.92% due to the decrease of mass, volume expansion, thermo-induced porosity and cracks on the surface of samples. According to the microscopic observation and statistical calculation, the porosity of the sample increases first and then decreases with the increase of the test temperature. The maximum porosity is 7.81% at 180℃ and then decreases at 200℃. Herein, it is considered that a large number of cracks and debonding between HMX grains caused by phase transformation at 180℃, which makes the porosity of PBX increase. Then the refinement of the grains fills a part of the voids resulting in a recovery of porosity at 200℃. However, the change of porosity is not affected by binder since no melting occured.