作者简介:郭双锋(1983-),男,高级工程师,从事火炸药技术研究。E-mail:gsf588325@163.com 通信作者:董军(1982-),男,高级工程师,从事高能炸药及装药技术研究。E-mail:94180853@qq.com !![Massive Preparation and Characterization of Superfine PETN by Mechanical Ball Milling Method] G

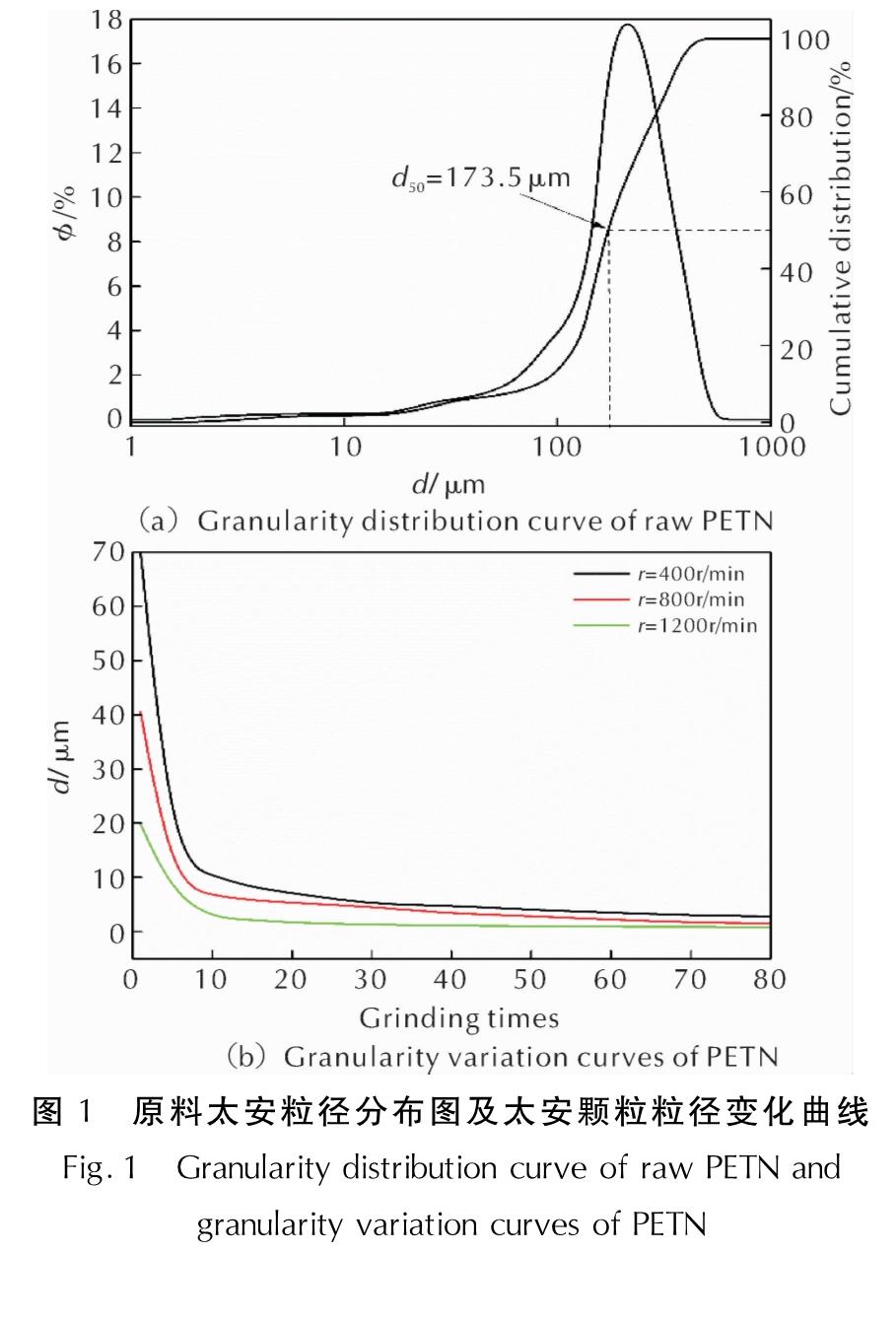

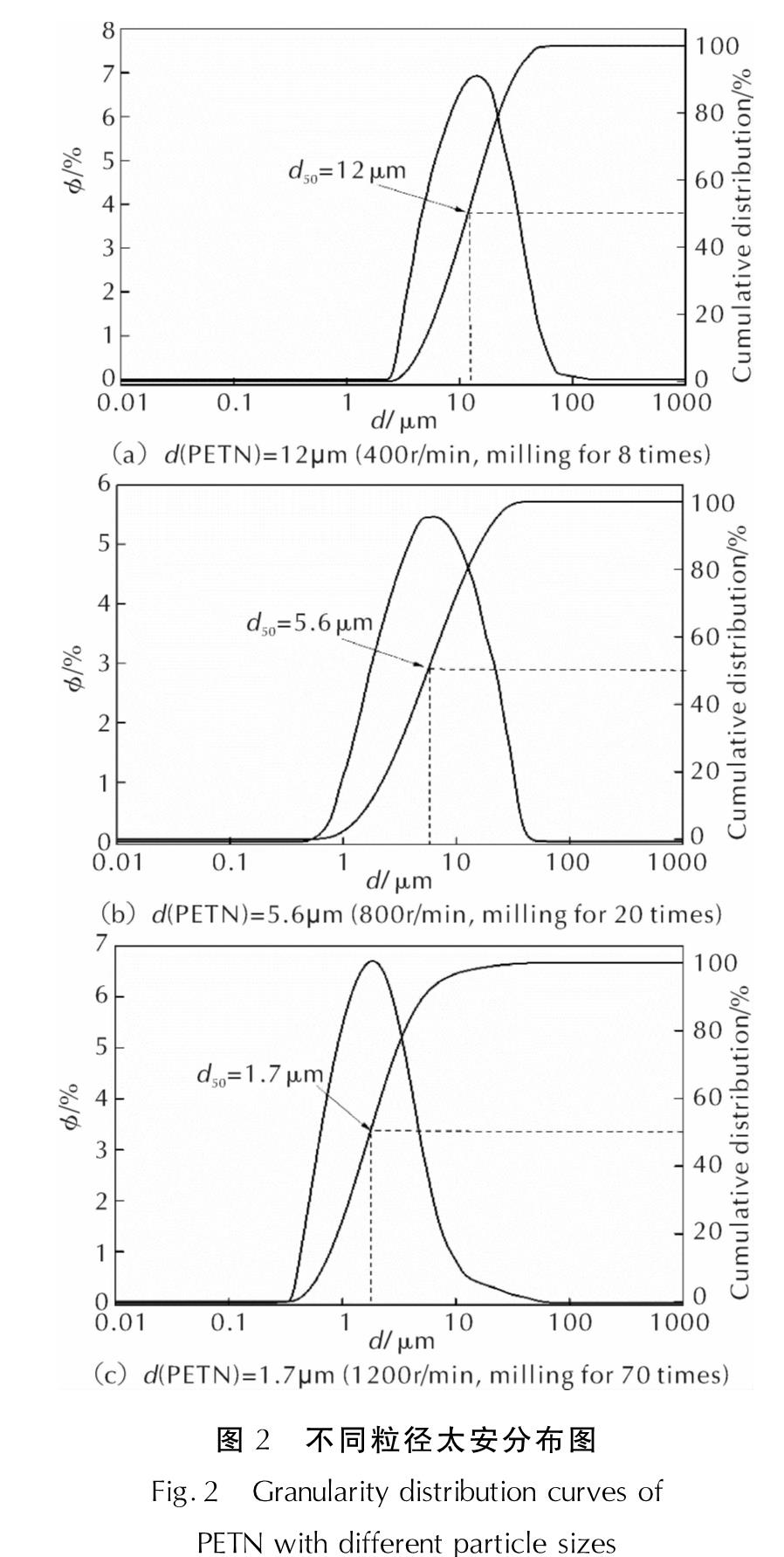

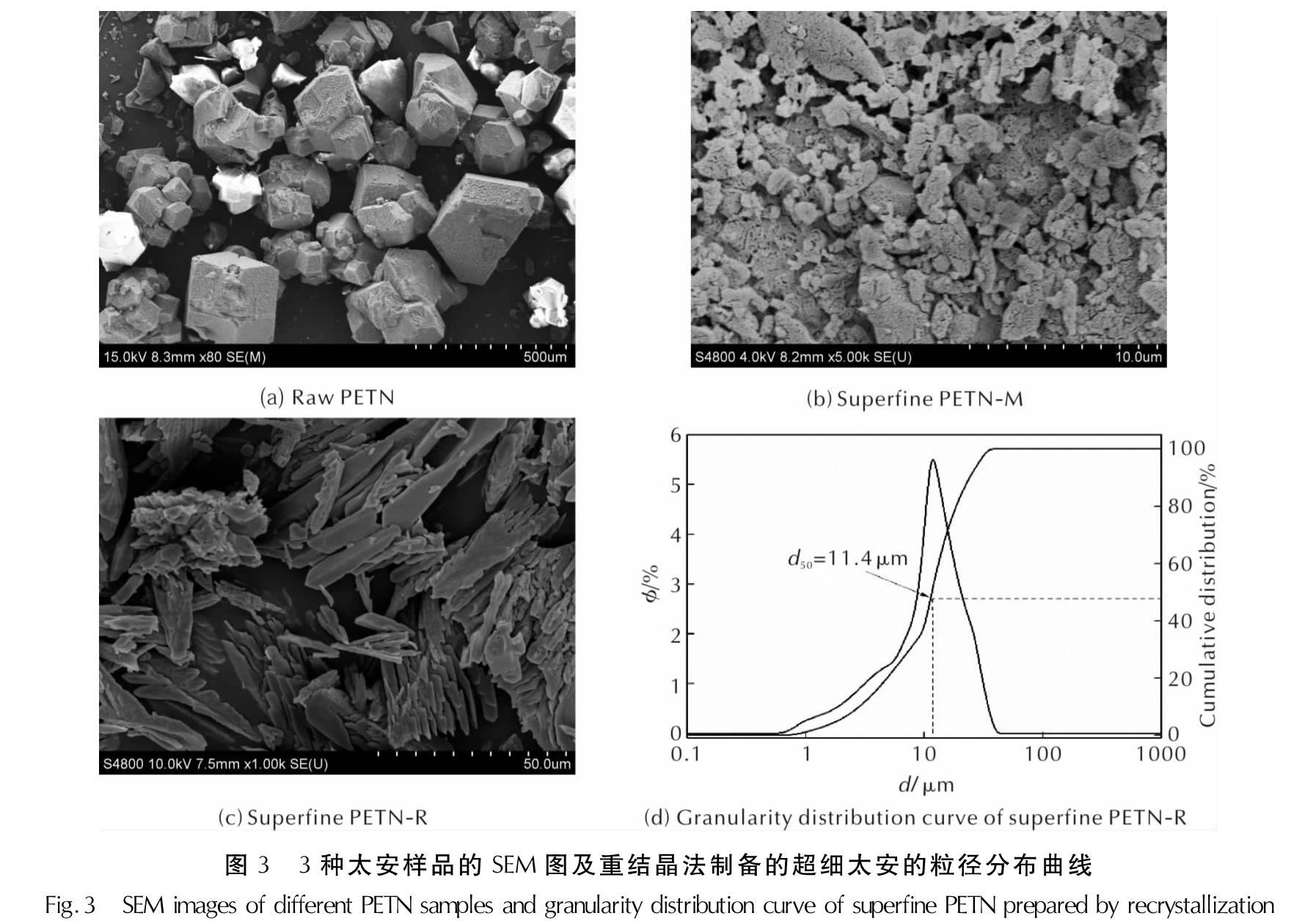

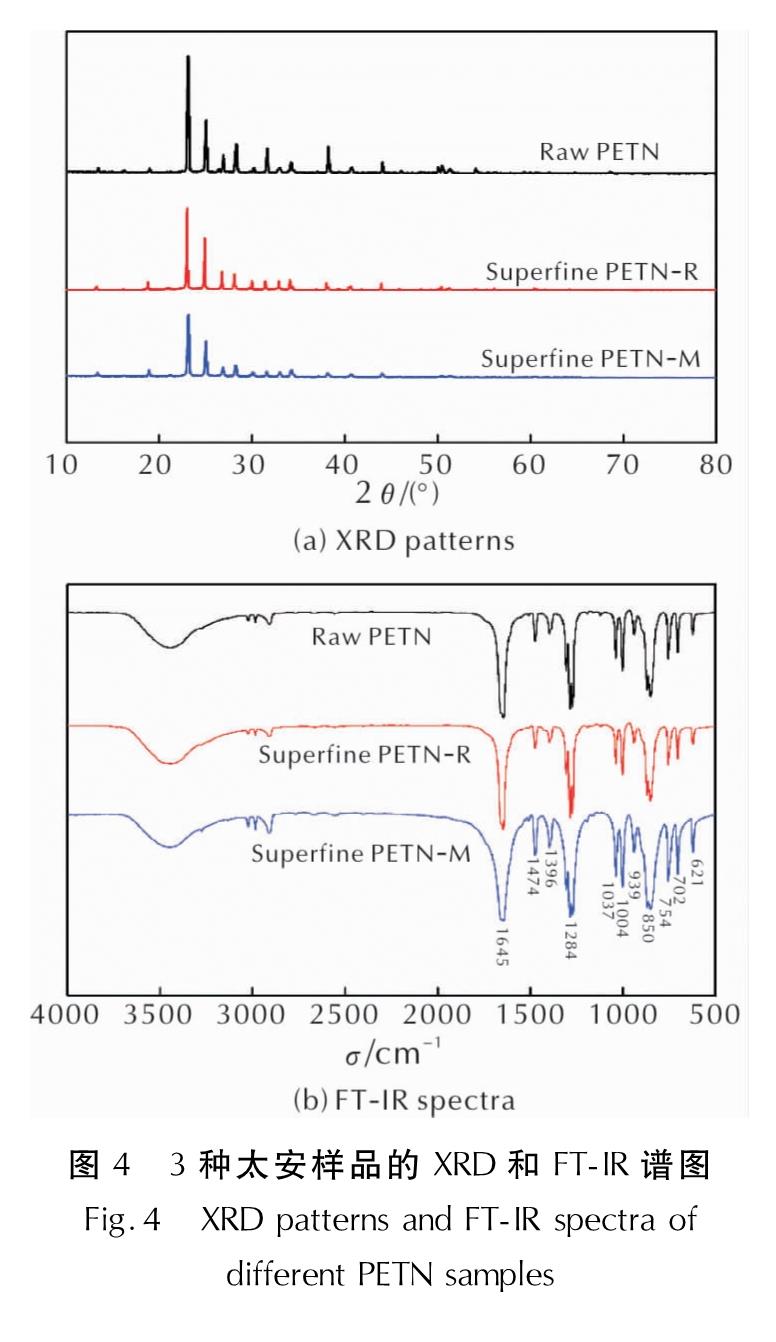

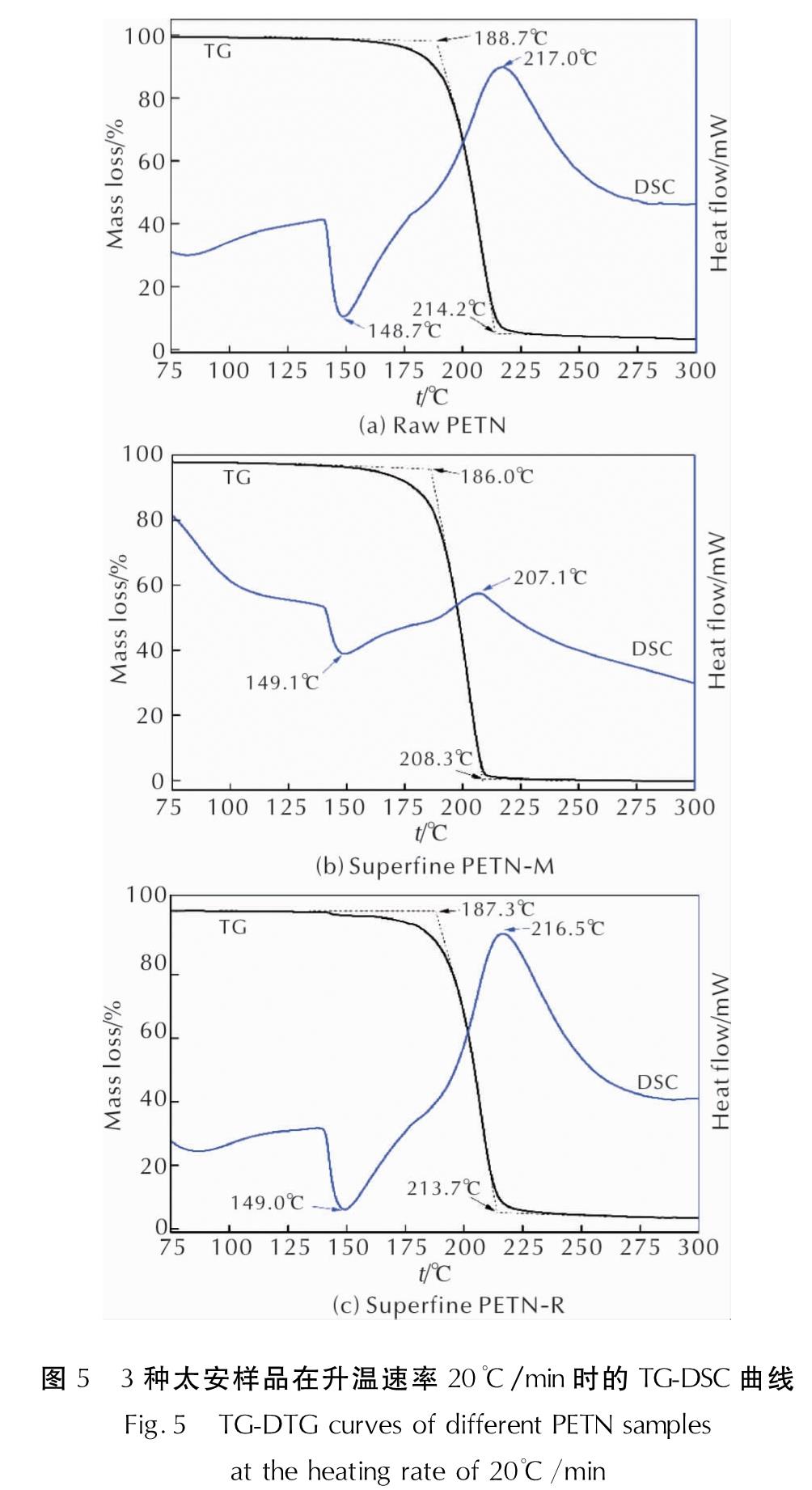

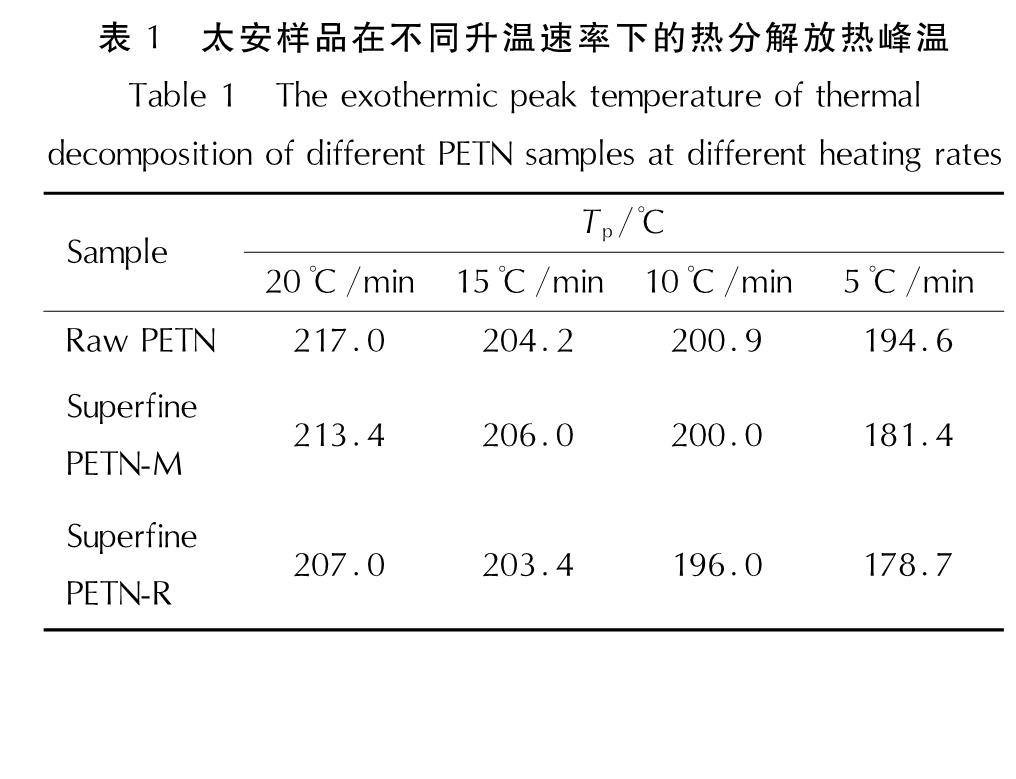

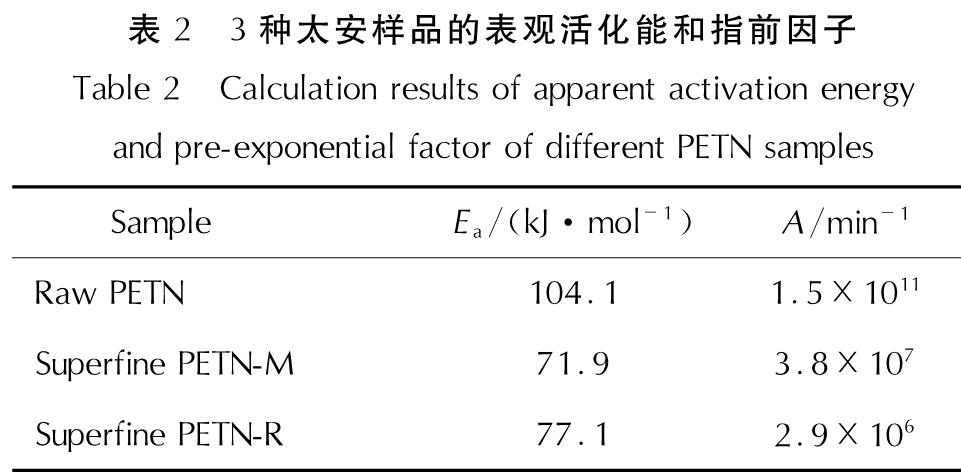

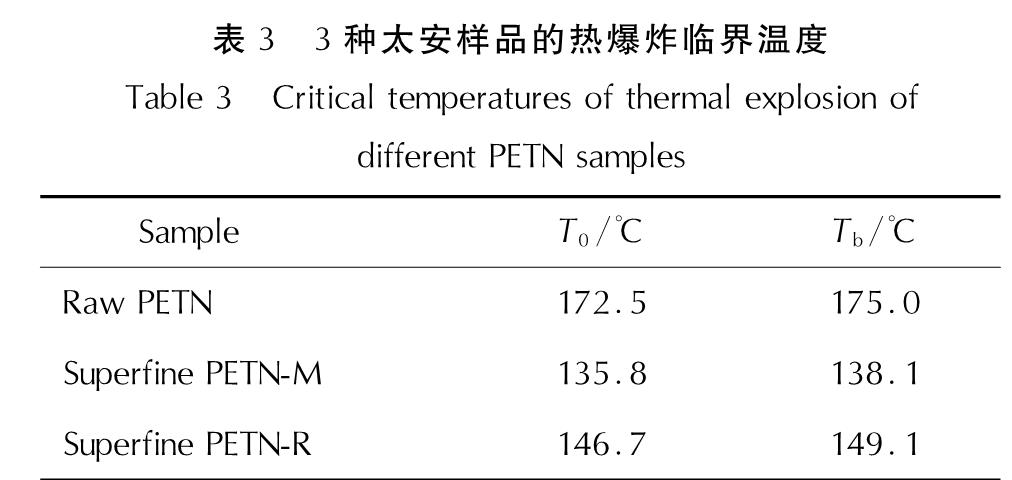

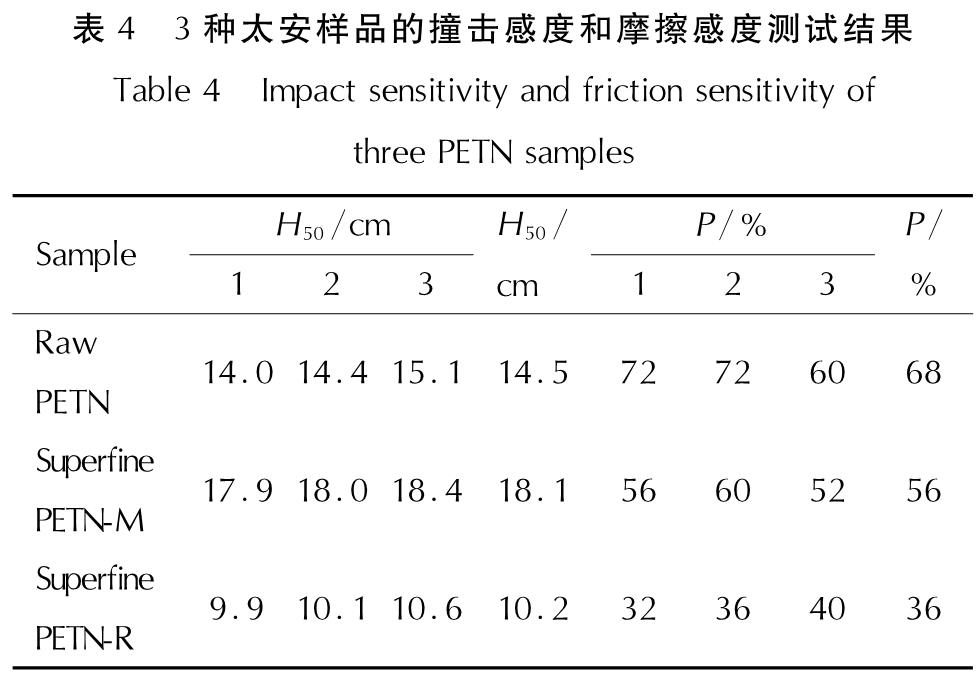

为实现超细季戊四醇四硝酸酯(太安)的批量化和绿色制备,采用机械粉碎法,配合真空冷冻干燥技术,成功获得分散性良好、粒径在1~20μm分段可控的超细太安粉体; 作为对比,同时也采用溶剂-非溶剂重结晶法得到超细太安颗粒; 通过扫描电镜(SEM)、X射线衍射法(XRD)和傅里叶红外光谱(FTIR)表征样品的形貌结构,采用热重与差示扫描量热同步热分析仪(TG-DSC)研究样品的热分解性能,结合机械感度测试评价样品的安全性能。结果 表明,与原料太安相比较,机械粉碎法制备的超细太安颗粒粒径在1μm左右,棱角大大减少,部分颗粒偏类球形,而重结晶法制备的超细太安颗粒平均粒径约11.4μm,呈片层状结构; 两种方法得到的太安晶型及分子结构均未发生改变,但放热峰温明显提前,活化能由104.1kJ/mol分别降至71.9kJ/mol和77.1kJ/mol,热爆炸临界温度由175.0℃分别降至138.1℃和149.1℃,热稳定性有所下降; 机械粉碎法制备的超细太安撞击感度下降24.8%,摩擦感度下降17.6%,而重结晶法得到的超细太安撞击感度增加29.7%,摩擦感度降低47.1%。采用机械粉碎法可实现超细太安的批量化、粒径可控、低成本及绿色制备。

In order to achieve massive and green preparation of superfine pentaerythritol tetranitrate(PETN), mechanical ball-milling method and vacuum freeze drying technique were applied and superfine PETN powders with good dispersity and controllable particle sizes between 1-20μm were successfully prepared. At the same time, another kind of superfine PETN particles were produced through solvent/non-solvent recrystallization method as a comparison. The morphology and structure of the two kinds of superfine PETN samples were characterized by SEM, XRD and FTIR. The thermal decomposition characteristics were analyzed by a TG-DSC simultaneous thermal analyzer, and the impact sensitivity and friction sensitivity were tested. The results showed that the particle size of superfine PETN with greatly reduced edges prepared by mechanical ballmilling method was about 1μm, and some of the particles were spherical, while the average particle size of superfine PETN with flake-like structure prepared by recrystallization was about 11.4μm. Besides, the crystal and molecular structures of both two kinds of superfine PETN had no change compared with raw PETN. The thermal decomposition temperatures of superfine PETN prepared by two kinds of methods were shifted to lower temperatures. The activation energies were decreased from 104.1kJ/mol to 71.9kJ/mol and 77.1kJ/mol, respectively, and the critical temperatures of thermal explosion were reduced from 175.0℃ to 138.1℃ and 149.1℃, respectively, indicating that the thermal stabilities were decreased. The mechanical sensitivity tests revealed that the impact sensitivity of superfine PETN prepared by mechanical ball-milling method had a decrease of 24.8% and friction sensitivity had a decrease of 17.6%. While the impact sensitivity of superfine PETN prepared by recrystallization had an increase of 29.7% and friction sensitivity had a decrease of 47.1%. The massive, low-cost and green preparation of superfine PETN with controllable particle sizes can be realized by mechanical ballmilling method.