作者简介:莫洪昌(1981-),男,高级工程师,从事高分子材料合成研究。E-mail:hongchangmo@163.com 通信作者:卢先明(1970-),男,研究员,从事高分子材料合成研究。E-mail:luxianming1220@126.com

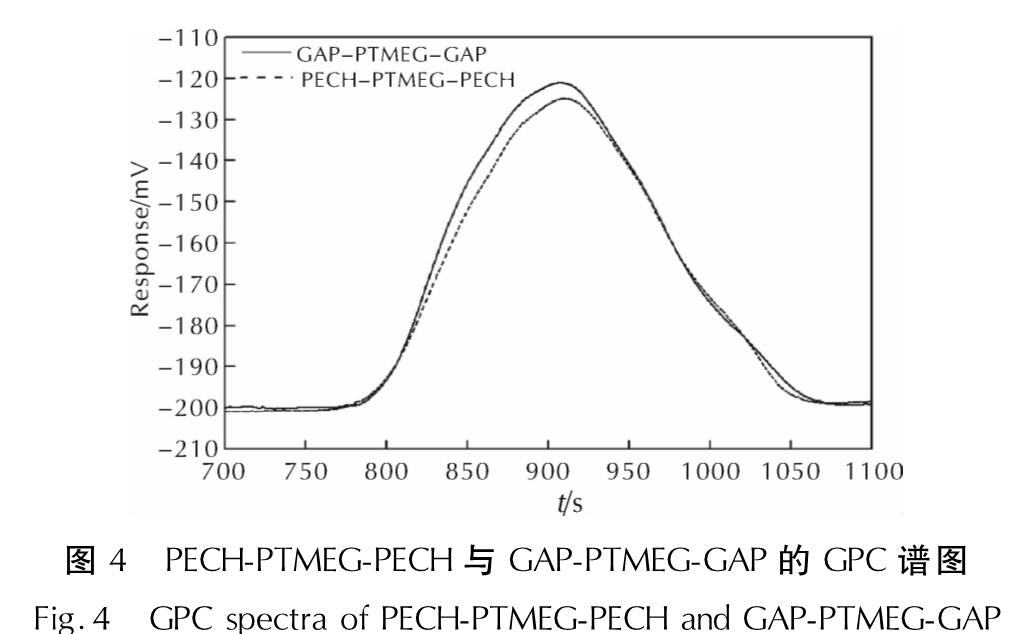

为了发展新型含能黏合剂,以聚四氢呋喃醚二醇(PTMEG)为引发剂,三氟化硼·乙醚络合物为催化剂,环氧氯丙烷(ECH)为单体,通过阳离子开环聚合反应,制备出端羟基聚环氧氯丙烷-聚四氢呋喃-聚环氧氯丙烷(PECH-PTMEG-PECH),PECH-PTMEG-PECH经过叠氮化反应得到端羟基聚叠氮缩水甘油醚-聚四氢呋喃-聚叠氮缩水甘油醚(GAP-PTMEG-GAP)。通过红外光谱、核磁共振氢谱、碳谱、凝胶渗透色谱和差示扫描量热法对共聚醚的结构及性能进行了表征。结果 表明,PECH/PTMEG链段比与投料比基本吻合,共聚醚的相对分子质量可控、分布较窄,叠氮化时间为28h,共聚醚的玻璃化转变温度为-58.6℃,黏度为3.5Pa·s,热分解峰温为256.6℃,与丁二酸二丙炔酯在60℃固化后得到的聚三唑弹性体具有较好的力学性能,拉伸强度(δm)最大为1.04MPa,断裂伸长率(εb)最大为73%,优于GAP基聚三唑弹性体。

In order to develop new energetic binders,triblock copolyether PECH-PTMEG-PECH was synthesized by the cationic ring-opening polymerization of epichlorohydrin,using polytetrahydrofunan ether glycol(PTMEG)as macroinitiator, boron-trifuoride ethylether complex (BF3·OEt2)as the catalyst, then GAP-PTMEG-GAP was prepared by the azidation of PECH-PTMEG-PECH.The copolyether was characterized by IR,1H NMR,13C NMR,GPC and DSC. The results show that the enchained ratio of PTMEG and PECH in the copolyethers is same with the calculated feed ratio, the relative molecular mass is controllable and relative molecular mass distribution is relatively narrow, the time of azidation is 28h, the glass transition temperature of copolyether is-58.6℃, the viscosity of copolyether is 3.5Pa·s, the decomposition peak temperature of copolyether is 256.6℃, the mechanical properties of polytriazole film cured by bis-propargyl-succinate(BPS)are 1.04MPa for tensile strength and 73% for elongation at break at room temperature, and its mechanical properties are better than GAP based polytriazole elastomer.