作者简介:陈坤(1995-),男,硕士,从事炸药爆炸能量输出特性研究。E-mail:chenkunen@163.com 通信作者:王伯良(1964-),男,博士,教授,从事爆炸理论及其应用研究。E-mail:boliangwang@163.com

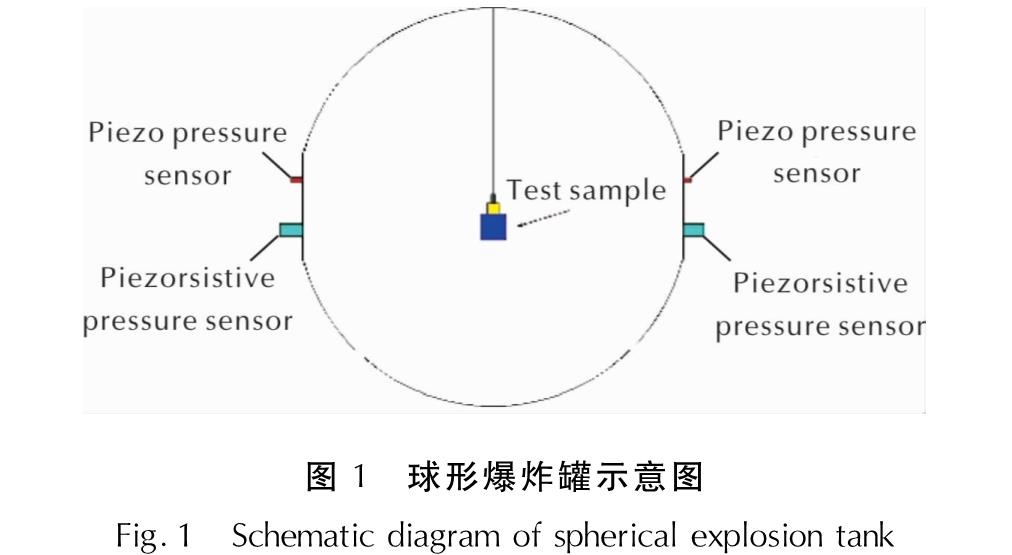

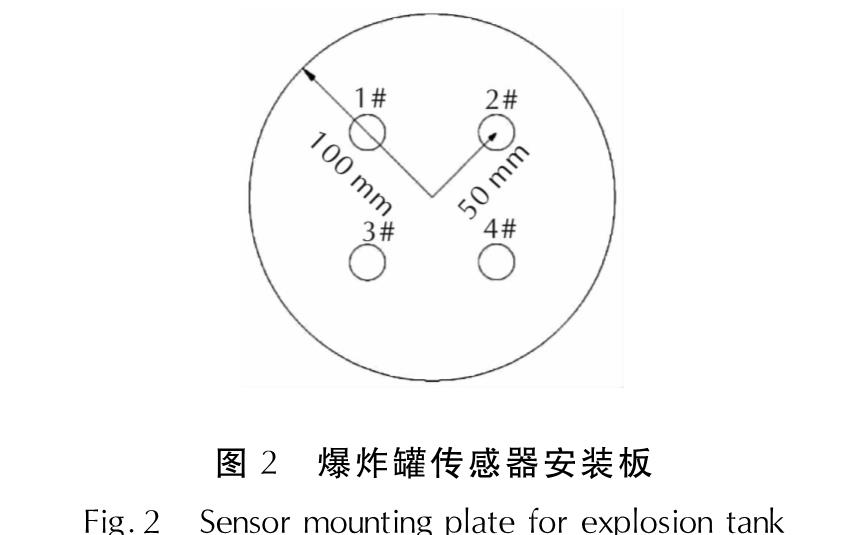

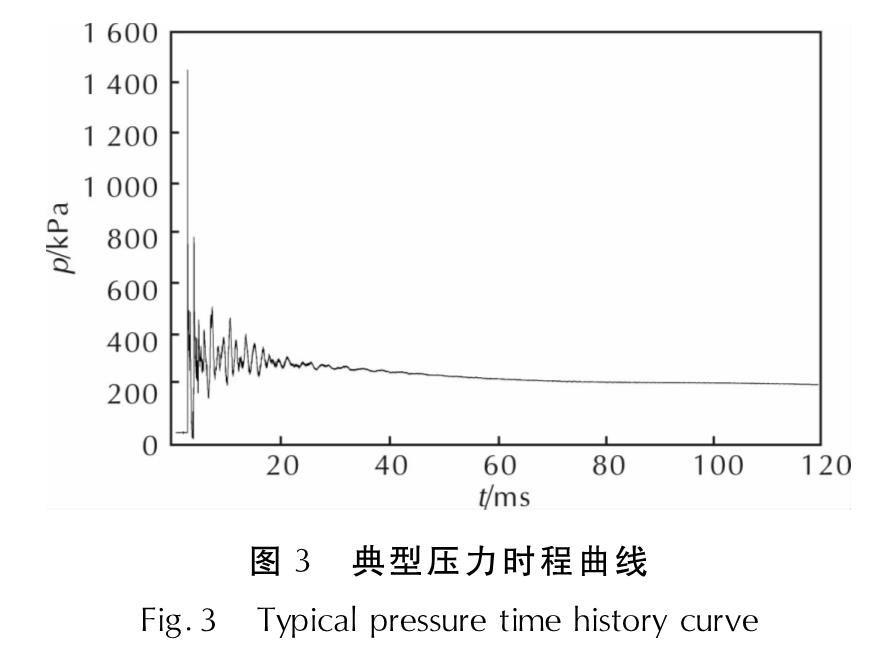

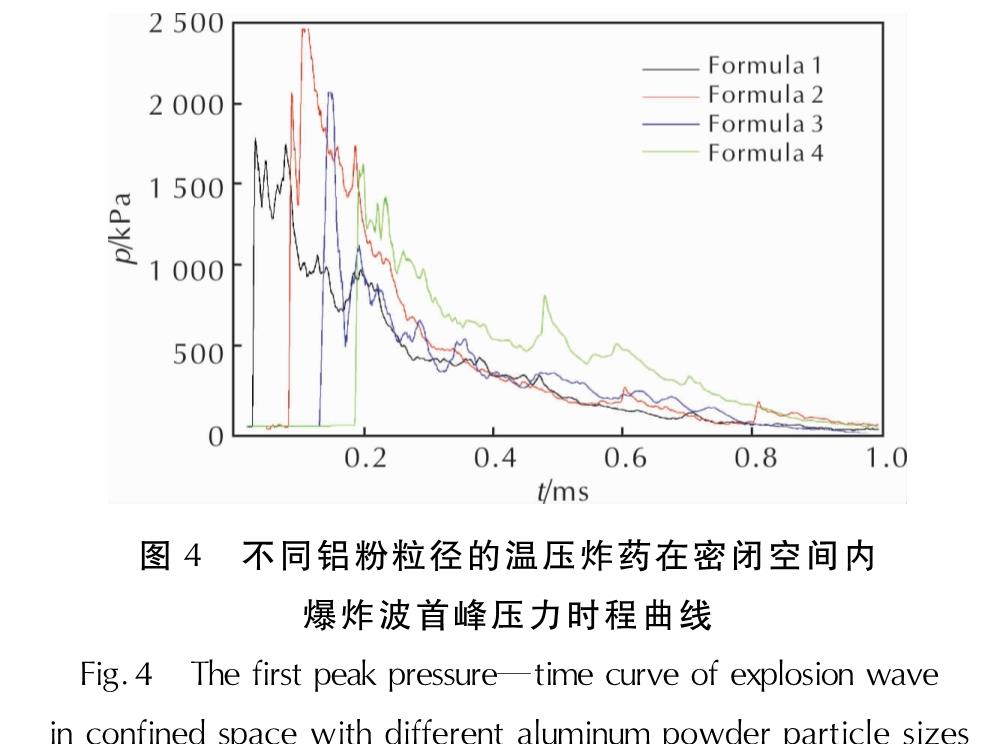

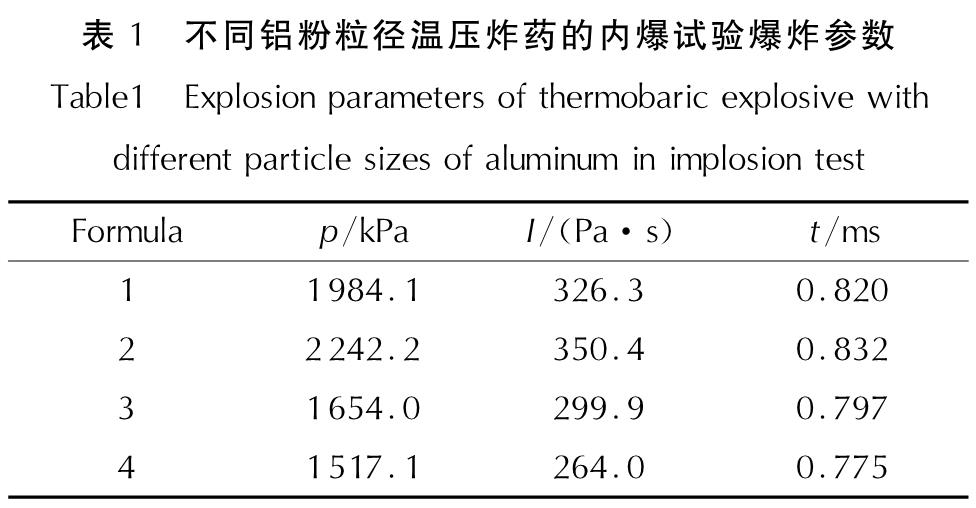

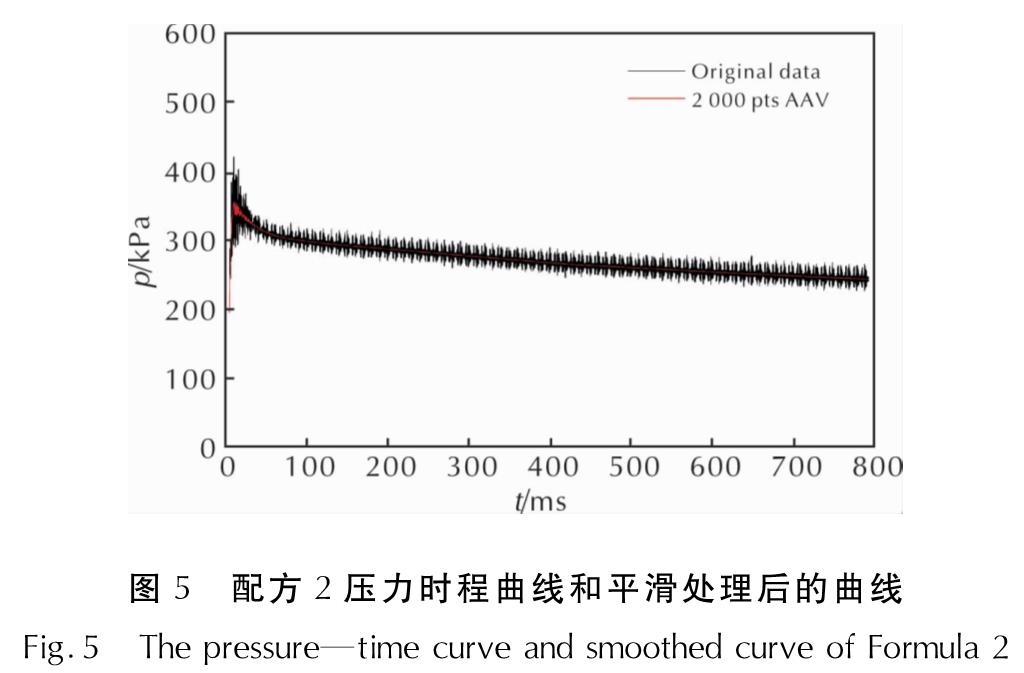

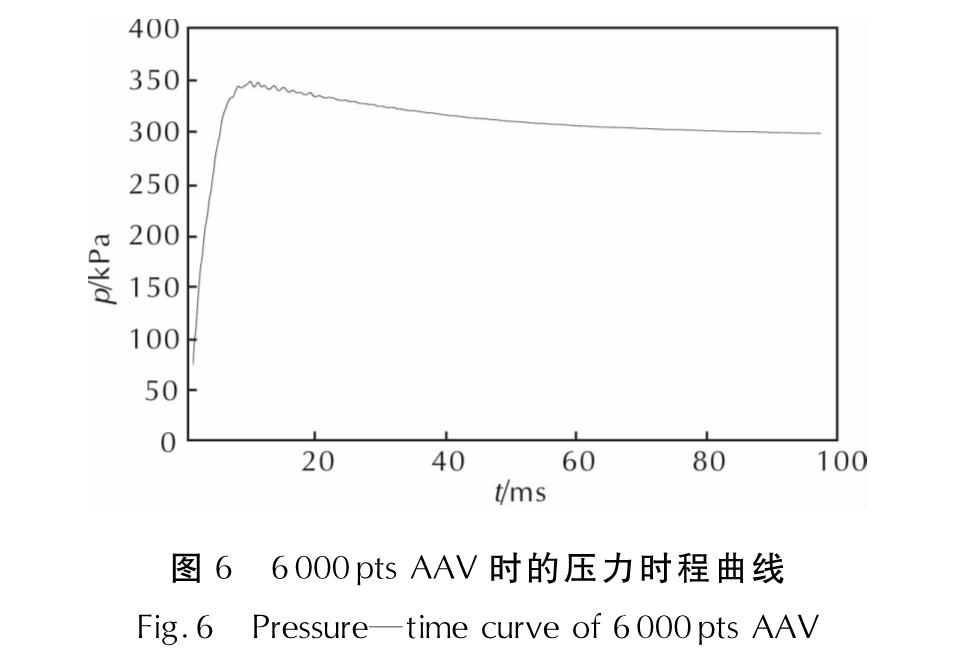

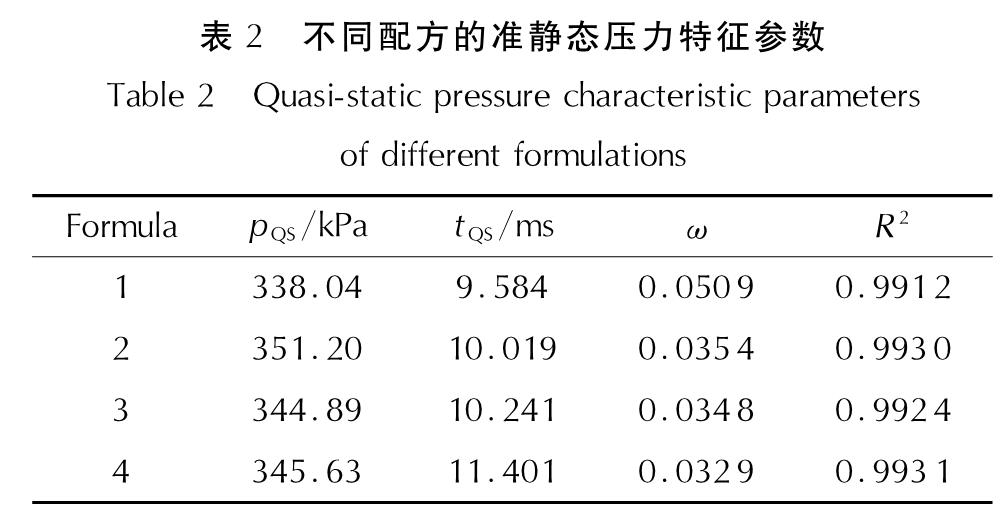

为研究铝粉粒径对HMX基温压炸药在密闭空间爆炸参数的影响,对铝粉中位径(D50)分别为2.7μm(配方1)、5.4μm(配方2)、23.8μm(配方3)和96.9μm(配方4)的HMX基温压炸药在球形爆炸罐进行了内爆试验,利用压力测试系统测得了爆炸后的反射波压力曲线,根据反射波超压峰值、冲量、准静态压力、准静态压力上升时间和压力衰减系数5个特征参数分析爆炸能量输出特性。结果 表明,随着铝粉粒径的增加,反射波超压和冲量呈先增加后减少的趋势; 配方2的反射波超压和冲量最大,分别比配方1高13%和7.4%,比配方3高35.6%和16.8%,比配方4高47.8%和32.7%; 配方2的准静态压力PQS最高,分别比配方1高3.9%,比配方3高1.8%,比配方4高1.6%; 准静态压力上升时间长短依次为:配方1<配方2<配方3<配方4; 压力衰减系数大小依次为:配方1>配方2>配方3>配方4。表明铝粉粒径对反射波压力和准静态压力影响较大。

To study the effect of aluminum particle size on the explosion parameters of HMX-based thermobaric explosive in confined space, the explosion test was carried out for the HMX-based thermobaric explosive with aluminum particle median diameters(D50)of 2.7μm(Formula 1), 5.4μm(Formula 2), 23.8μm(Formula 3)and 96.9μm(Formula 4). The reflected wave overpressure curve was measured in a spherical explosion tank device by a pressure test system. The explosion energy releasing characteristics was analyzed according to five characteristic parameters of reflected wave overpressure peak, impulse, quasi-static pressure, rise time of quasi-static pressure and pressure decay coefficient. The results show that with increasing the particle size of aluminum powder, the reflected wave overpressure and impulse increase at first and then decrease. The overpressure and impulse of the reflection wave are the largest for Formula 2, which are 13% and 7.4% higher than those of Formula 1, 35.6% and 16.8% higher than those of Formula 3, 47.8% and 32.7% higher than those of Formula 4, respectively; When the particle size of aluminum powder is 5.4μm, the quasi-static pressure pQS is the highest, 3.9% higher than that of Formula 1, 1.8% higher than that of Formula 3 and 1.6% higher than that of Formula 4 respectively; the rising time of quasi-static pressure decreases as Formula 1 < Formula 2 < Formula 3 < Formula 4, and the decreasing coefficient of pressure increases as Formula 1>Formula 2>Formula 3>Formula 4,showing that the particle size of aluminum powder has great influence on the reflected wave pressure and quasi-static pressure.