作者简介:高霞(1988-),女,博士研究生,从事含能材料应用研究。E-mail:18630658732@163.com 通信作者:罗观(1972-),男,研究员,从事含能材料应用研究。E-mail:luoguan@caep.com

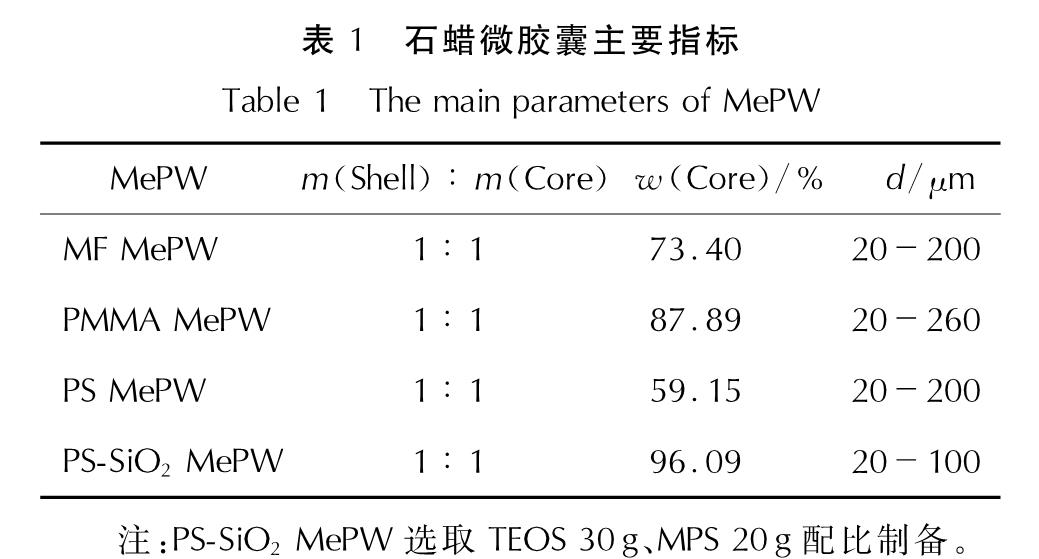

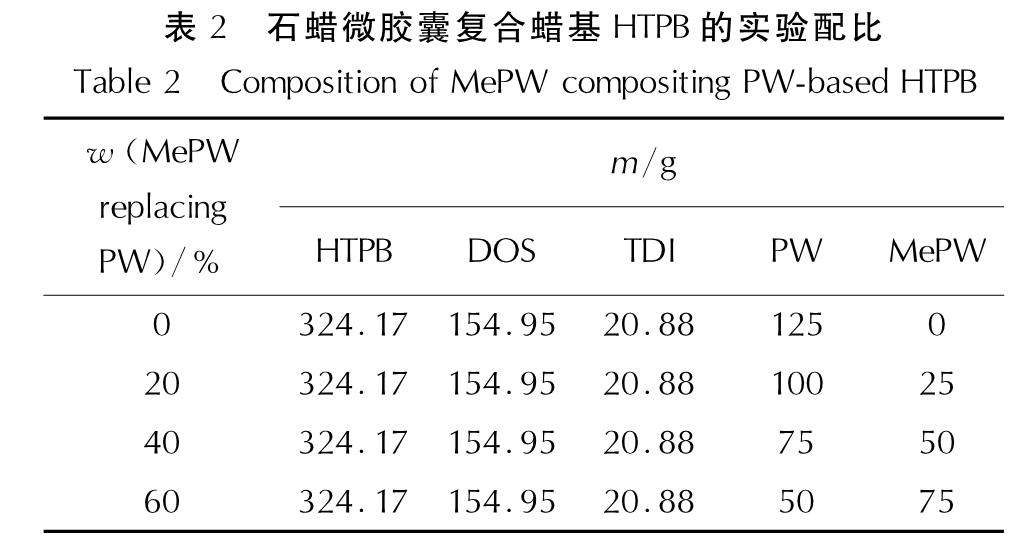

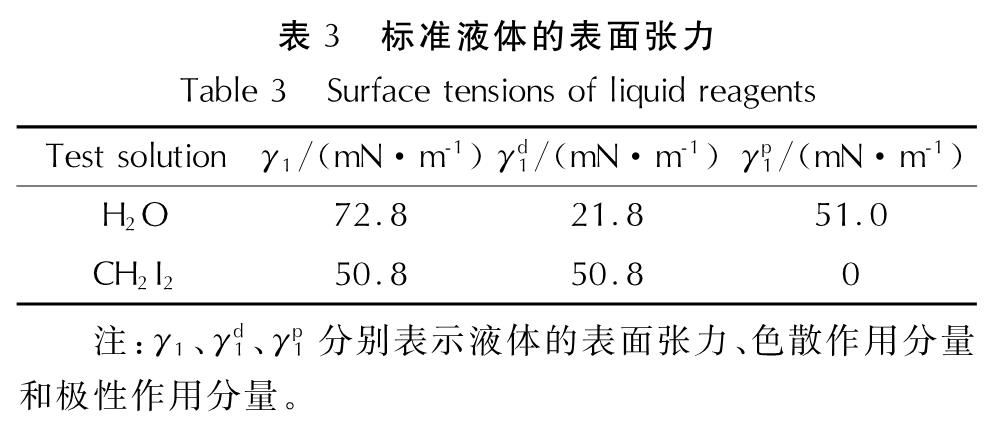

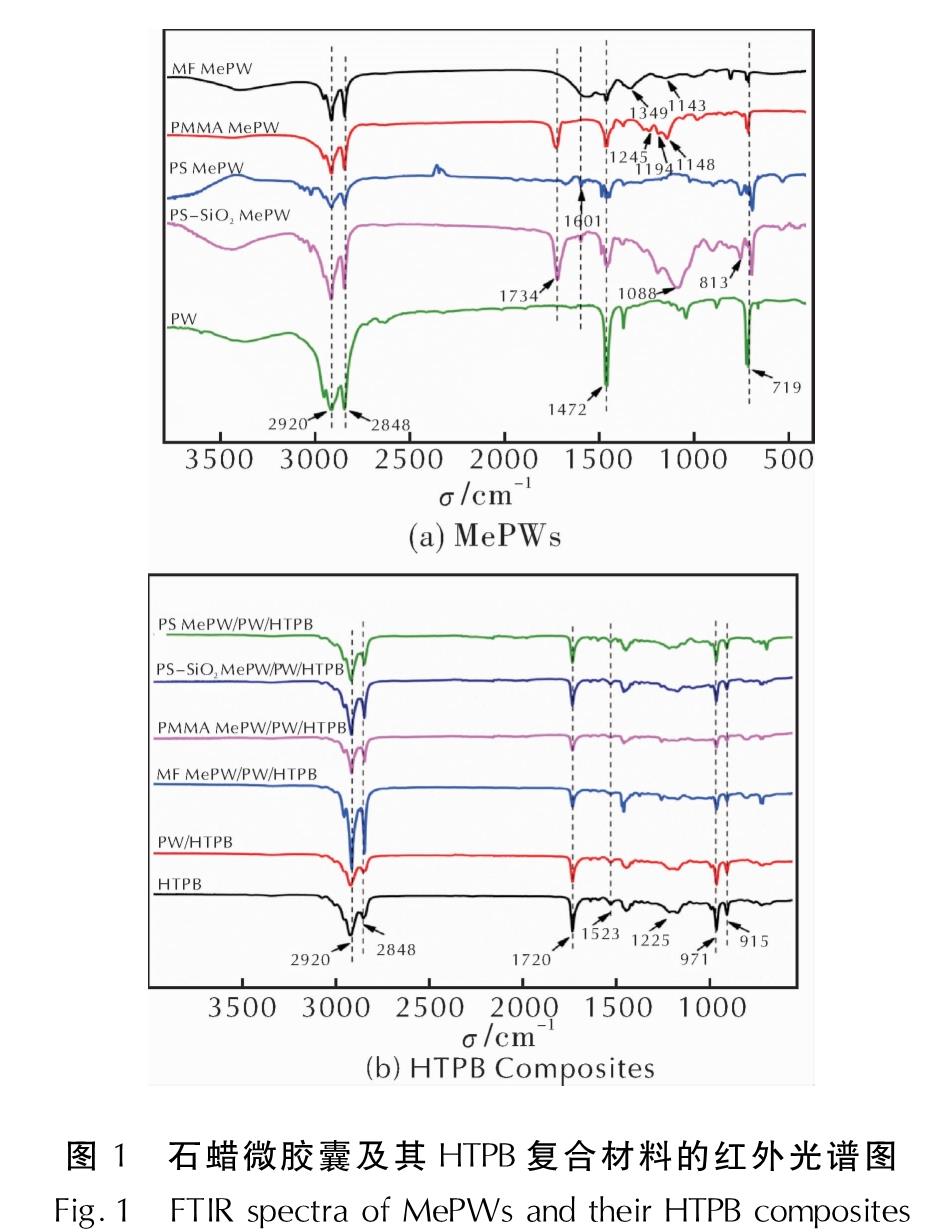

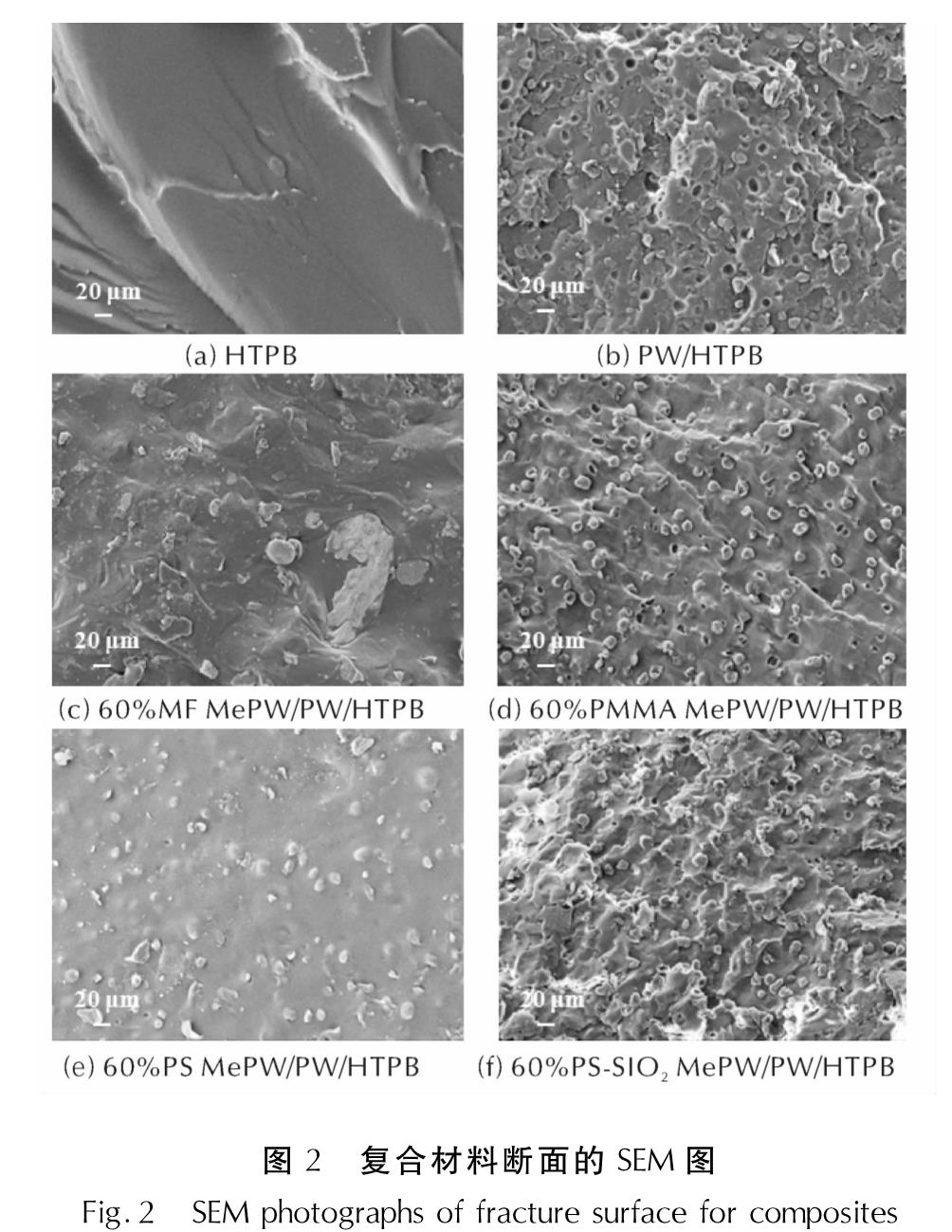

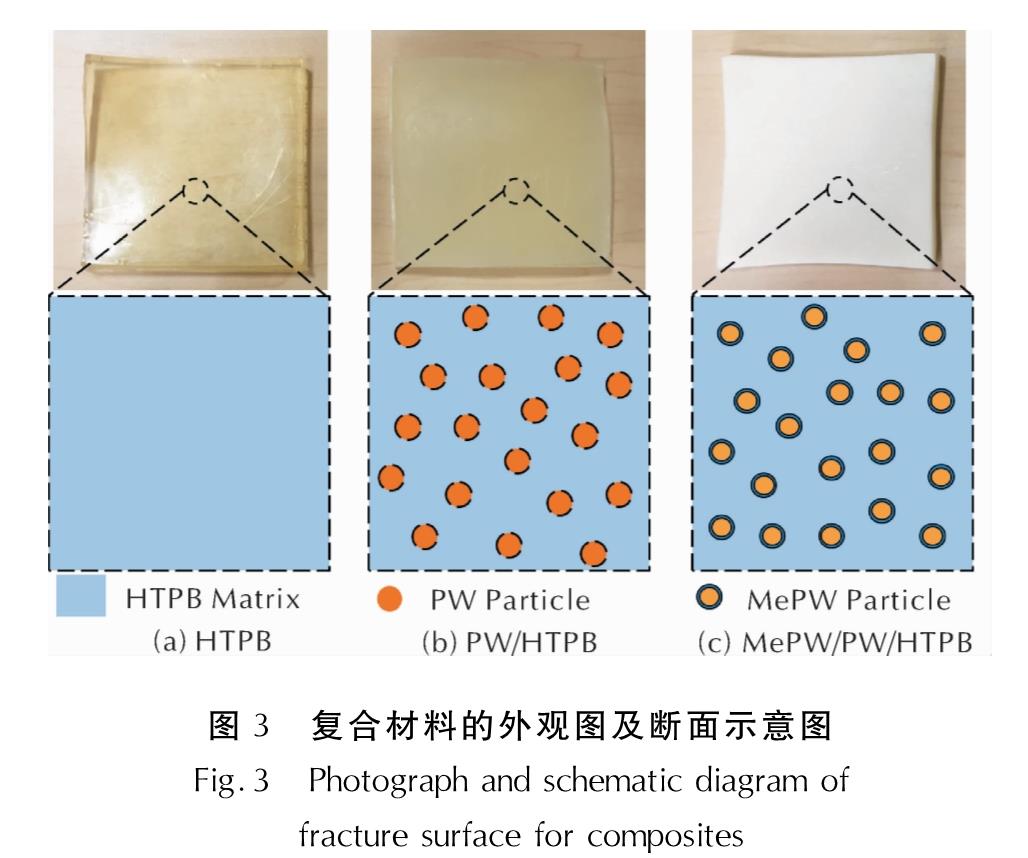

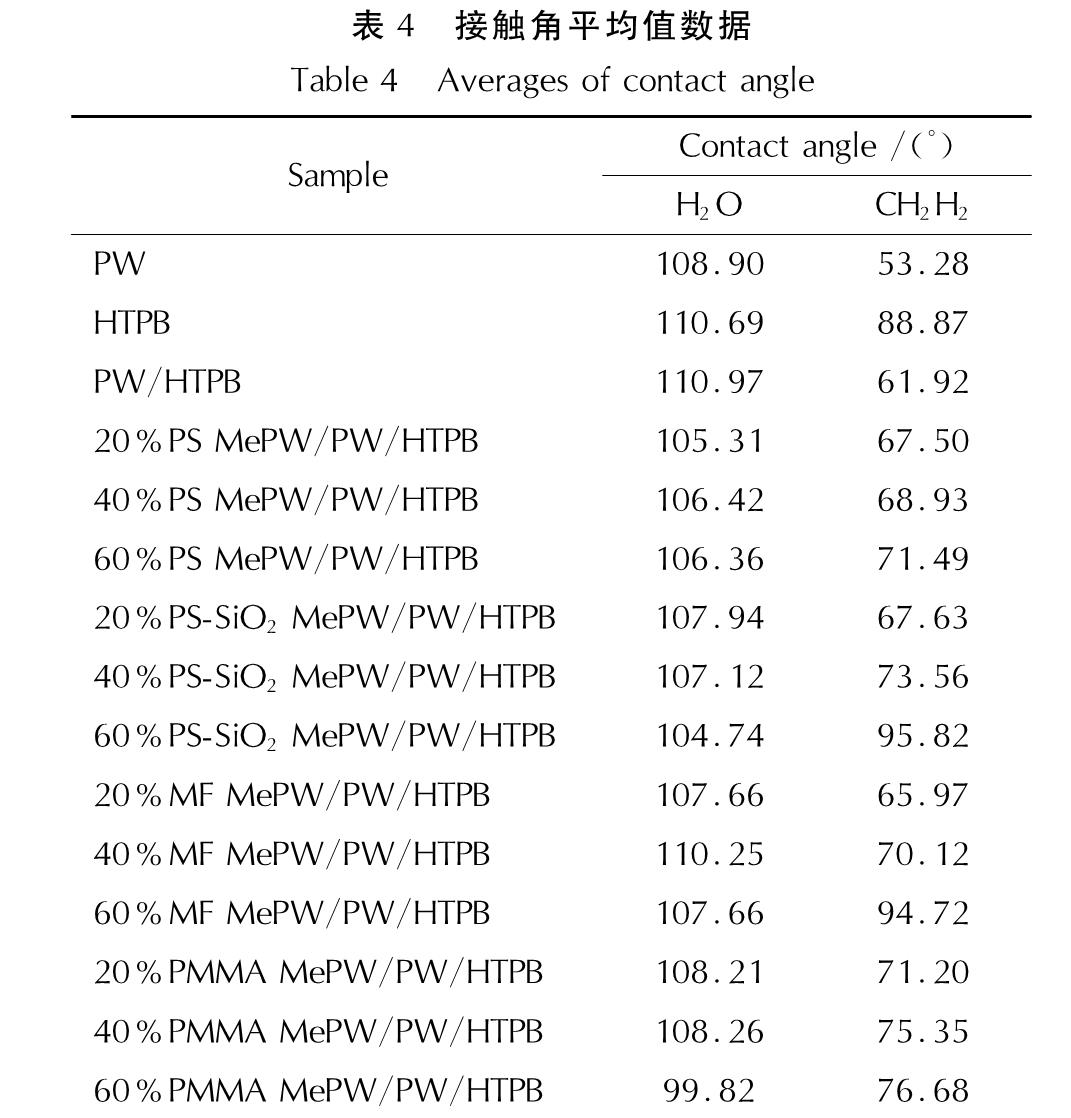

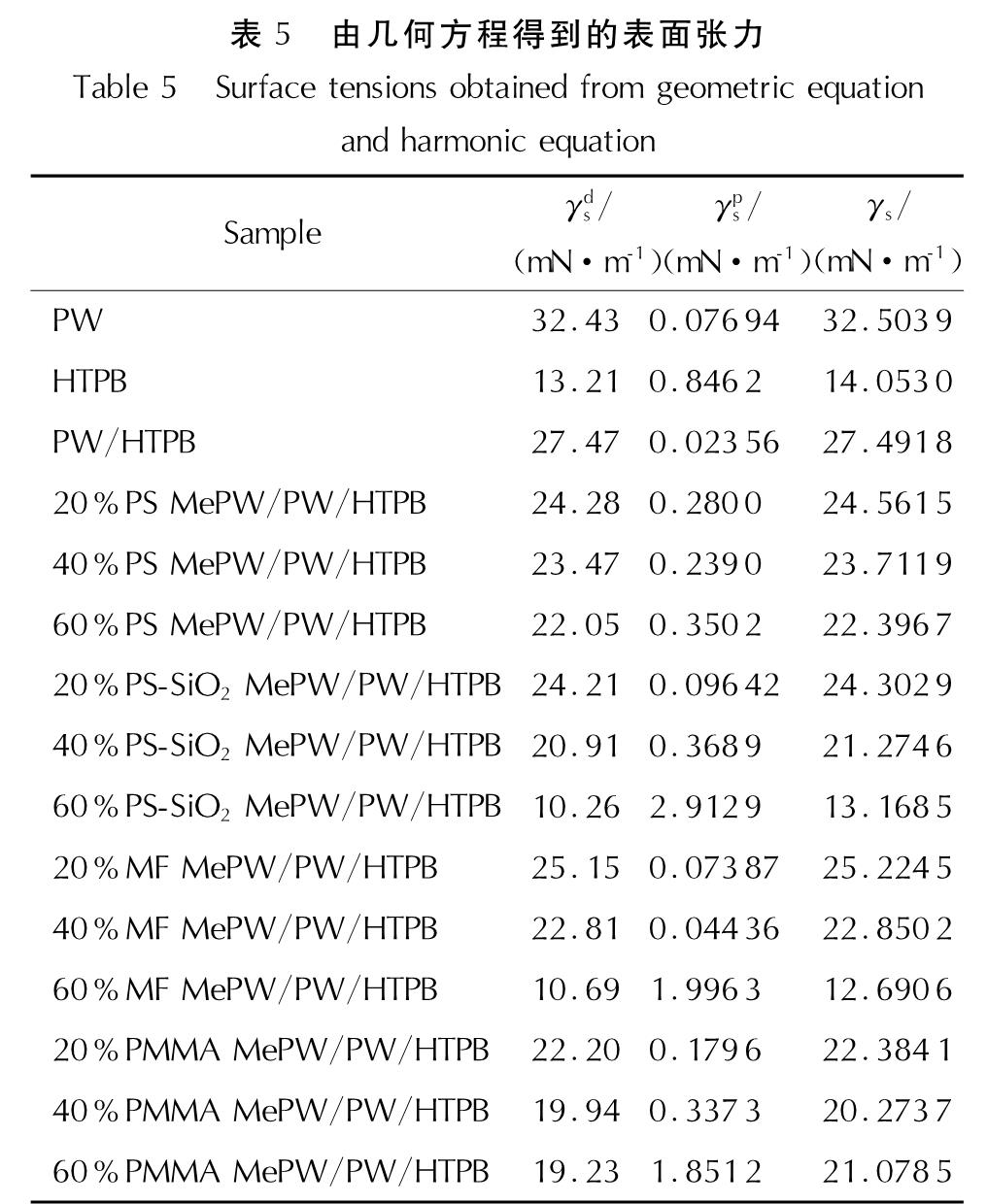

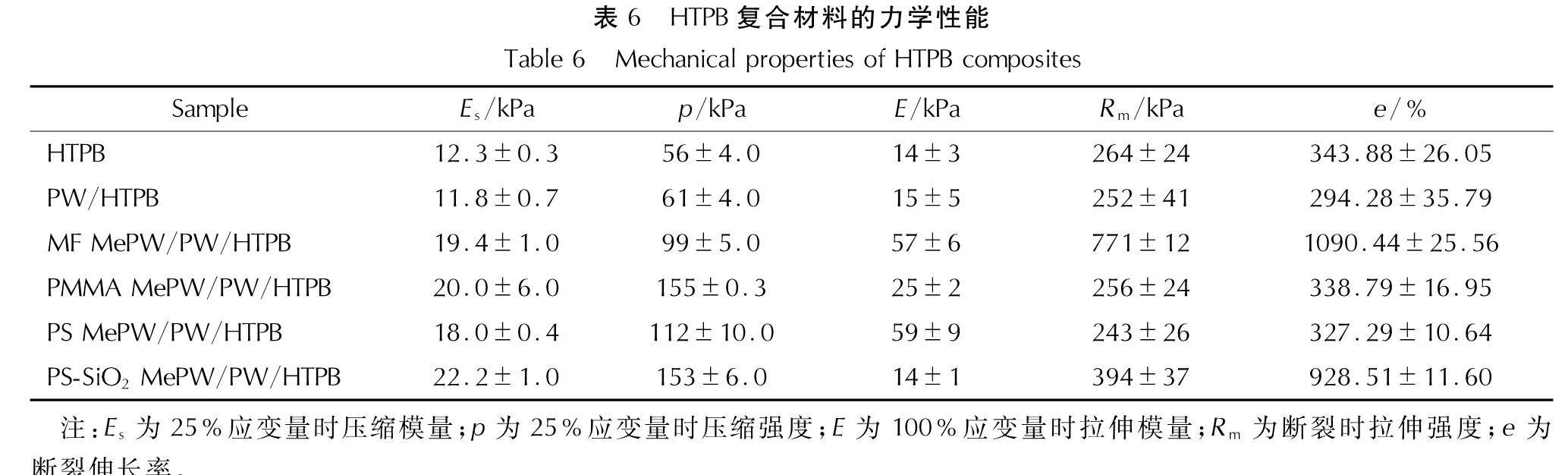

为了解决聚合物黏结炸药(PBX)中小分子石蜡钝感剂力学性能差、与高分子黏结剂相容性不佳等问题,基于不同壁材石蜡微胶囊(MePW)的合成,采用浇注成型的方法,制备其与石蜡、端羟基聚丁二烯型聚氨酯(HTPB)的复合材料; 研究了该复合材料的化学组成、脆断面形貌、表面和界面热力学性质、力学性能,以及它们之间的关系。结果 表明,加入MePW可以有效减少石蜡从HTPB基体脆断面脱离,以MF MePW和PS MePW改善效果最佳。与PW/HTPB相比,加入MePW后使材料表面张力(γs)最高降低了14.8012mN/m(60%MF MePW/PW/HTPB),明显提高石蜡与HTPB间的相容性; 同时力学性能显著增强,其压缩模量、压缩强度、拉伸模量、拉伸强度和断裂伸长率最高分别提高了10.4kPa(PS-SiO2 MePW)、94kPa(PMMA MePW/PW/HTPB)、44 kPa(MF MePW/PW/HTPB)、519kPa(MF MePW/PW/HTPB)和796.16%(MF MePW/PW/HTPB)。由此可见,4种壁材MePW中,MF MePW对PW/HTPB的改性效果最显著,最有利于其在PBX体系的应用。

To solve the problem of poor mechanical properties and it has the bad compatibility with the micromoieacule paraffin wax(PW)as desensitizer of the polymer binder in polymer bonded explosive(PBX), the composites of MePW, PW and hydroxyl-terminated polybutadiene(HTPB)were prepared by cast molding method, based on the synthesis of MePW with different shells. The chemical composition, fracture surface morphology, thermodynamics properties of surface and interface, mechanical properties of these composites and the relationship among them were investigated. The results indicated that the addition of MePW could effectively reduce the divorce of PW from the fracture surface of HTPB matrix, and the best composites were MF MePW and PS MePW. Compared with PW/HTPB, the surface tension(γs)of the material decreased by 14.8012mN/m(60%MF MePW/PW/HTPB)and the compatibility between PW and HTPB was significantly improved by adding MePW. Meanwhile, the mechanical properties were significantly enhanced. The compression modulus, compression strength, tensile modulus, tensile strength and elongation at break of the materials increased by 10.4kPa(PS-SiO2 MePW/PW/HTPB), 94kPa(PMMA MePW/PW/HTPB), 44kPa(MF MePW/PW/HTPB), 519kPa(MF MePW/PW/HTPB)and 796.16%(MF MePW/PW/HTPB), respectively. It can be seen that among the MePWs with four kinds of shell materials, MF MePW has the most significant modification effect on PW/HTPB, which has the most posibility to apply for PBX system.