作者简介:张世潇(1995-),男,硕士研究生,从事爆轰与起爆机理研究。E-mail:18811105786@163.com 通信作者:仝毅(1962-),男,教授,从事爆轰学与爆炸冲击动力学研究。E-mail: tongyi@bit.edu.cn

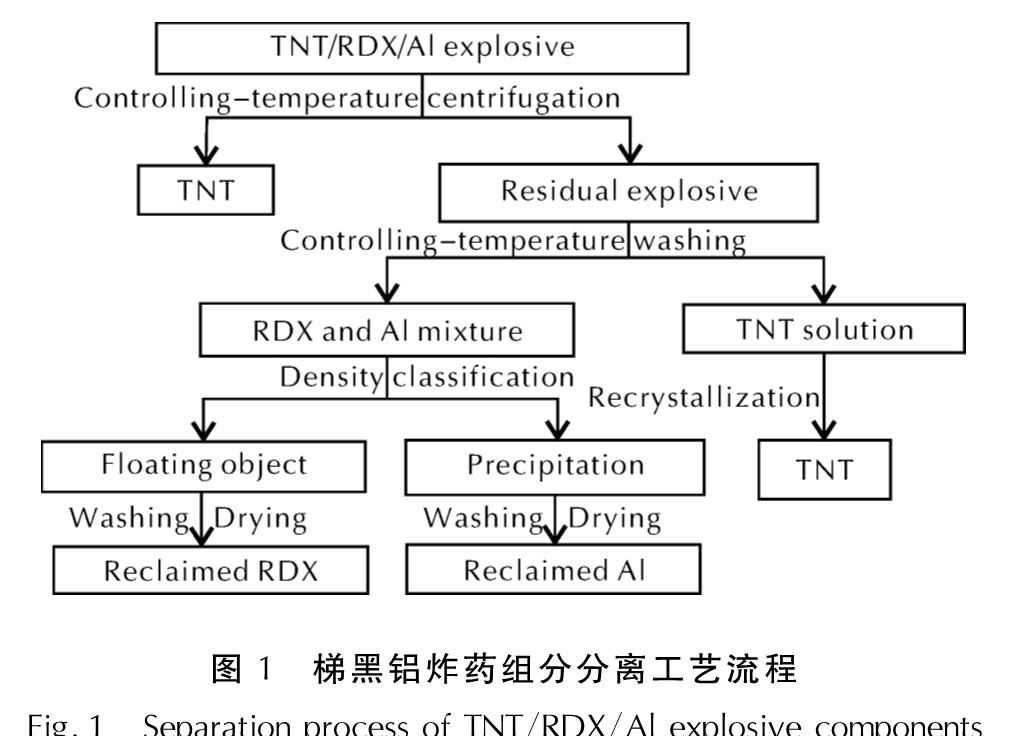

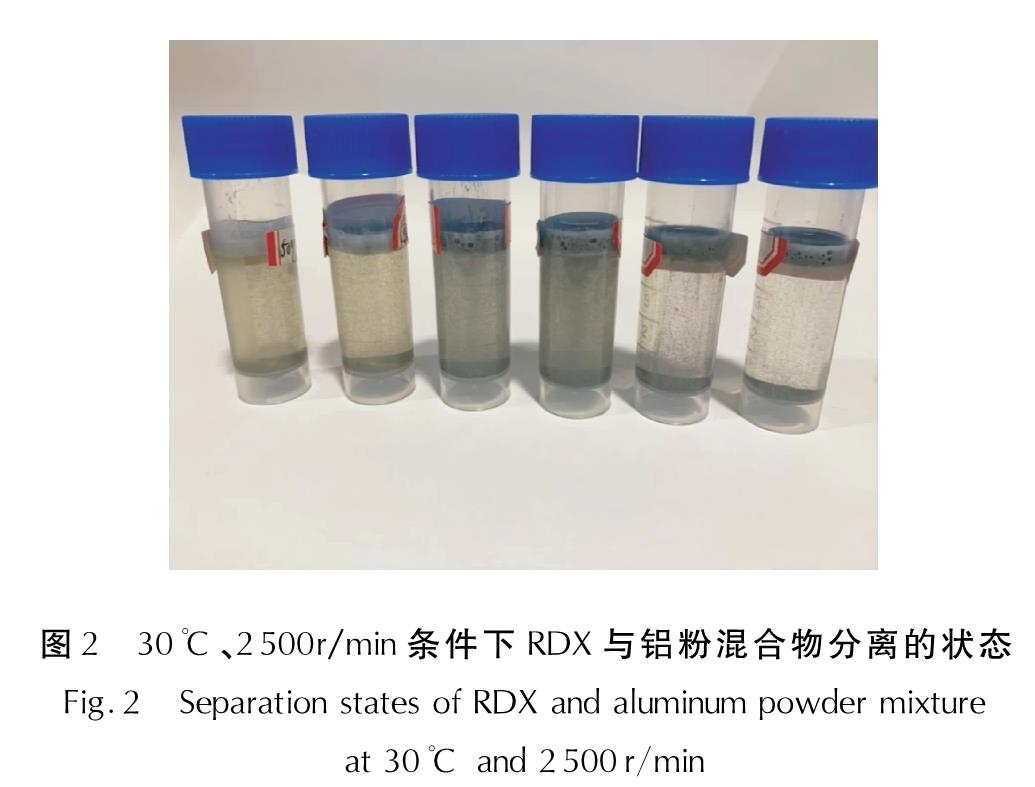

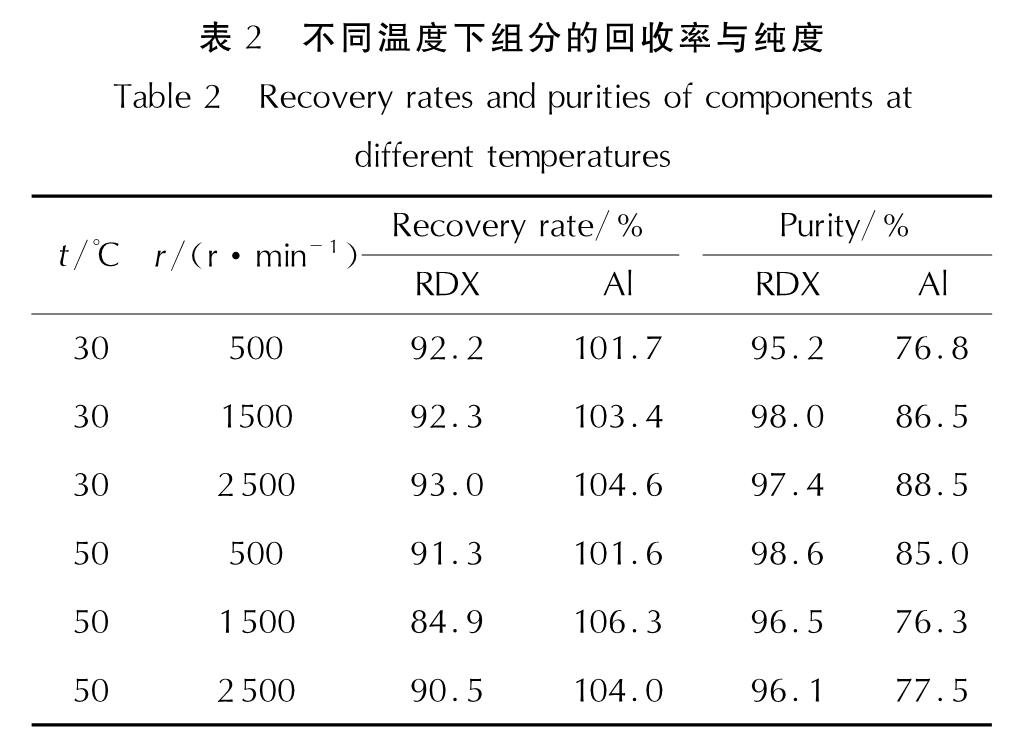

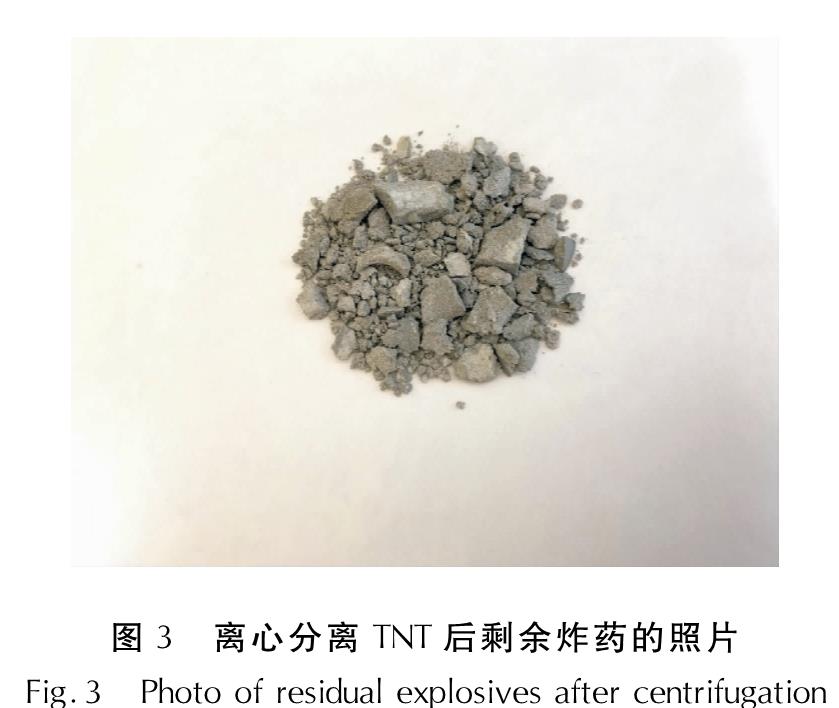

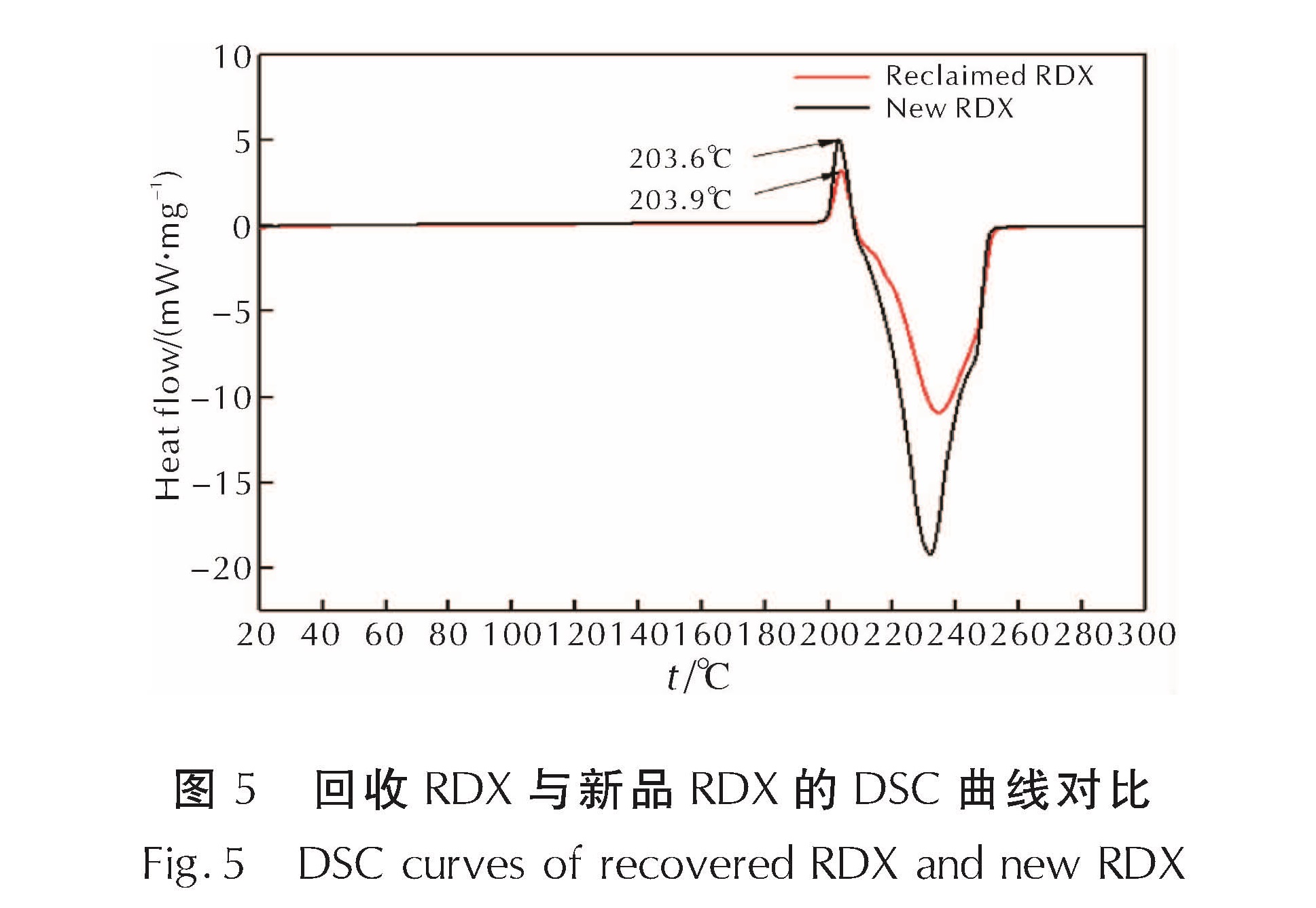

为了研究分离回收废旧梯黑铝炸药中各成分的高效低成本的物理方法,采用控温离心和控温水洗结晶,回收梯黑铝炸药中的TNT组分; 再根据RDX与铝粉的密度差异,使用密度分级法,分离RDX与铝粉, 优化了分离条件,对回收物质进行DSC和XRD表征,并测试其撞击感度。结果 表明,在密度为2.0g/cm3的溴化锌溶液中,控温30℃、离心转速2500r/min等条件下,回收RDX和铝粉回收率分别为67.6%和86.5%,纯度分别为77.2%和94.6%; 回收的RDX热安定性良好,存在少量铝粉和TNT与RDX的共熔物,且基本没有独立存在的TNT组分,其撞击感度为90%; 回收铝粉中含有微量氧化铝粉和炸药成分; 两种回收物组分中均不含溴化锌。该物理方法可有效实现废旧梯黑铝炸药各组分的高效绿色回收。

In order to study the efficient and low-cost physical method of separating and recycling the components of TNT/RDX/Al explosive, the component of TNT was recovered by controlling-temperature centrifugation and controlling-temperature washing and recrystallization, and the RDX and aluminum powder were separated by density classification according to the different densities between RDX and aluminum powder. The separation conditions were optimized. The recovered materials were characterized by DSC and XRD, and their impact sensitivities were tested. The results show that the recovery rates of RDX and aluminum powder were 67.6% and 86.5%,with the purities of 77.2% and 94.6%, respectively under the condition of zinc bromide solution(density of 2.0g/cm3), reaction temperature 30℃ and centrifugal speed 2500r/min. The recovered RDX has good thermal stability, containing a small amount of aluminum powder and TNT-RDX eutectic, and basically there is no independent TNT, and its impact sensitivity is 90%. The recovered aluminum powder contains trace amounts of alumina powder and explosive components. There is no zinc bromide in either of the recovered components. This physical method adopted can effectively realize the efficient and green recovery of various components from waste TNT/RDX/Al explosive.