基金项目:国家自然科学基金(No.22275150)

作者简介:陈颖(1998-),女,硕士研究生。E-mail:chenying05250318@163.com

通信作者:沈金朋(1982-),男,博士,副教授。E-mail:sjp0388@163.com

裴重华(1968-),男,博导,教授。E-mail: peichonghua@swust.edu.cn

(1.西南科技大学 材料与化学学院,四川 绵阳 621010; 2.西南科技大学 国防科技学院,四川 绵阳 621010; 3.西南科技大学 环境友好能源国家重点实验室,四川 绵阳 621010; 4.中国工程物理研究院化工材料研究所,四川 绵阳 621900)

(1.School of Materials and Chemistry, Southwest University of Science and Technology, Mianyang Sichuan 621010, China; 2.School of National Defense Science and Technology, Southwest University of Science and Technology, Mianyang Sichuan 621010, China; 3.State Key Laboratory of Environment-friendly Energy Materials, Southwest University of Science and Technology, Mianyang Sichuan 621010, China; 4.Institute of Chemical Materials, China Academy of Engineering Physics, Mianyang Sichuan 621900, China)

additive manufacturing; gallium-based liquid metal; GLM; micron aluminum powder; fluoropolymer; 3D printing; burning

DOI: 10.14077/j.issn.1007-7812.202311023

受原子堆砌方式、化学键能的限制,传统的由C、H、O、N四种元素组成的炸药能量密度提高的空间有限,其极限密度仅为2.3g/cm3,体积能量密度最高仅为12.6kJ/cm3,爆轰性能提高潜能只能达到30%[1,2]。因此,亟待研发满足未来武器使用的高能量密度含能材料。

近年出现了由两种或多种非炸药类固体物质所组成的亚稳态反应性材料(nano Al-氟聚物[3]、nano Al-CuO[4]、nano Al-Fe2O3[5]等)。由于氧化组分和还原组分处于纳米尺度,克服了固相化学反应传质距离大的动力学缺陷,具有高绝热温度、高能量密度、高反应速度和低传质距离等特点[6,7],广泛应用于微型含能器件、火箭推进剂和绿色火工药剂等领域[8]。其中,由于氟聚物中氟元素(F)具有极强的电负性,Al-氟聚物反应体积能量密度可达33kJ/cm3。氟聚物中的F可以对Al2O3起到活化作用,在一定程度上抵消Al2O3氧化层导致的点火延迟现象,进一步提高其燃烧速率[9]。马里兰大学H. Wang等[10]利用墨水直写技术制备了nano Al/PVDF(偏二氟乙烯的聚合物)、nano Al/Viton(六氟丙烯和偏二氟乙烯的二元共聚物)和nano Al/THV(四氟乙烯、六氟丙烯和偏二氟乙烯的三元共聚物)3种不同Nano Al-氟聚物反应性材料,并系统对比了3种材料的机械性能、点火性能及燃烧特性。发现氟聚物中F含量越高,Al-氟聚物的火焰温度越高; 且氟聚物中H含量越高,燃烧过程中主要产生HF,HF能够与Al2O3壳层反应,促进预点火反应发生,降低反应活化能,使Al-氟聚物的点火温度和活化能越低。普渡大学Diane N. Collard等[11]研究了3种改变Al/PVDF反应速率的方法,包括:选择不同粒径的铝燃料、调整材料的化学计量比及将燃料颗粒从微米级改变为纳米级,发现调节Al颗粒粒径和化学计量比可以使燃速在17~40mm/s范围内变化。南京理工大学Y. Li等[12]对比了原始nano-Al粉末、nano-Al粉末和PVDF的物理混合物以及电喷雾法制备PVDF活化的nano-Al复合反应性材料,研究发现PVDF在复合体系中起氧化剂的作用,即使以机械混合的方式将少量PVDF加入到nano-Al粉中也能显著改善点火和燃烧性能。

但是nano-Al粉易被氧化而降低活性铝含量,其能量密度便难以保证,从而进一步阻碍铝与氟聚物之间的相互作用,将导致Al-氟聚物反应材料体系的非活性铝粉的质量增加[13]。且nano-Al混合时存在易团聚且不易被润湿[14]、在Al-氟聚物反应体系中燃烧不稳定等问题[14,15]。微米铝粉活性铝含量高,但是反应速度慢且不易反应完全,美国普渡大学Diane N. Collard等[11]研究了3种改变Al/PVDF反应速率的方法,发现纯micro-Al和PVDF具有最低的燃烧速率。

如何进一步改善Al-氟聚物反应体系的燃烧和力学性能是亚稳态反应性材料研究领域的挑战。2006年俄罗斯科学院M. V. Trenikhin等[16]研发了一种Ga-In液态金属改性微米铝合金,其能与水发生剧烈反应,主要原因是Ga-In液态金属进入铝颗粒晶格,使其发生从塑性到脆性断裂。2021年西南科技大学陈安等[17]利用液态金属GLM与Micro-Al作用制备了GLM-Al,其活性Al含量为91%,能量输出性能明显改善。当和高氯酸铵用至固体推进剂时,燃烧压力比液态金属改性前增加36.4%,热释放增加1kJ/g,且改性后凝聚相产物粒度明显减小[18]。主要原因是镓基液态金属破坏铝表面完整的钝化层,使铝颗粒中的铝核更易与氧化剂发生反应,从而促进铝基高能复合材料体系中的传质过程。

另外,传统装药存在材料消耗大、不易于制造复杂结构和表面、制造精度低、均质性低、过程繁杂以及生产效率低等缺点[19]。3D打印技术具有安全可靠、一致性好、易实现复杂结构装药成型等优点。本研究制备了25μm的液态金属改性微米Al粉,并通过3D打印制备了GLM-Al-氟聚合物复合反应性材料,研究了其结构和性能。

Al粉,粒径为25μm,成都科隆化工有限公司; 镓(Ga),铟(In),锡(Sn),纯度99.9%,阿拉丁生化科技股份有限公司; 氟聚物,阿拉丁生化科技股份有限公司; 正己烷,N,N-二甲基甲酰胺,分析纯(纯度≥99.9%),成都科隆化工有限公司。

将镓、铟、锡按照质量比68:22:10混合,70℃水浴加热搅拌1h得到液态金属,并用1mol/L NaOH同时超声洗净液体金属表面的氧化层。将制备好的镓基液态金属在手套箱中存放,防止氧化。

首先,称量1g原料Al粉及质量分数为1%、3%、5%、7%的GLM加入到15mL正己烷中。混合物使用磁力和超声(功率为100%)交替搅拌反应24h(超声3次,每次10min)。反应完成后,将其置于60℃真空干燥箱干燥12h,得到液体金属改性铝,分别记为1%GLM-Al、3%GLM-Al、5%GLM-Al、7%GLM-Al。

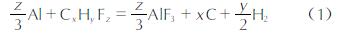

将2.9g氟聚物(偏二氟乙烯和三氟氯乙烯摩尔比为1:1共聚物)完全溶于20mL DMF中,使用机械搅拌12h,形成胶体溶液。Al-氟聚物通过化学计量计算,计算基于方程式(1)[10],其中Al质量分数为23.53%。随后分别加入当量比为2.0、2.5、3.0、3.5、4.0、5.0的GLM-Al,继续机械搅拌12h,得到均匀稳定的墨水。

使用3D打印机进行打印,使用0.84mm内径的喷嘴和80℃的基底加热台。图1是Al-氟聚物3D打印过程的示意图。打印路径为12cm×12cm,平台移动速度1mm/s,样品挤出速度0.08mL/min,打印层高0.3mm。随后将打印样品置于60℃真空干燥箱干燥24h,待测。

形貌表征:使用Ultra-55型(德国蔡司仪器有限公司)场发射扫描电子显微镜,对喷金后改性前后的铝粉和Al-氟橡胶的横截面进行微观形貌分析; 并对3%GLM-Al的元素分布进行分析。使用ESCALAB Xi+型(赛默飞世尔科技公司)X射线光电子能谱对3%GLM-Al表面的价态进行分析。

比表面积表征:使用BELSORP MaxII型(日本麦奇克拜尔公司)BET全自动比表面积分析仪,在77K液氮条件下,对原料Al、GLM-Al样品进行氮气吸脱附测试。

XRD表征:采用ULTIM Max 65型(英国牛津仪器公司)X射线衍射仪对改性前后Al粉及其热氧化产物的晶型进行表征,使用Cu靶Kα射线,测试波长λ=1.5406Å,扫描范围为5°~80°,工作电压和电流分别为40kV和40mA。通过与标准数据库比对,确定材料的物相组分和晶型。热氧化产物通过多次DSC-TG测试收集获得。

热分解性能:使用STA449F5型(德国耐驰仪器制造有限公司)热重-差式扫描量热分析仪对改性前后铝粉的热分解性能进行试验,氧气气氛(99.99%),样品量3mg,温度范围35~1200℃,升温速率10K/min。

流变性能:使用HR-10型流变仪(美国TA公司)测试Al-氟聚物墨水的流变性,剪切速率0.1~1001/s,剪切应变 0.01%~100%,流变仪底座温度设定为20℃/80℃,加载间隙1000.0μm。

燃烧测试:使用Plantomv 12.0,UX50型(日本活图隆公司)高速摄影仪,拍摄频率2000fps(1~3μm)/1000fps(25μm)(FPS:帧数/秒),在空气气氛中进行测试。点火装置:直流电源加热器,电压7.5V,加热金属为Cr20-Ni80合金电热丝(丝径0.4mm,长度3cm,电阻8.674Ω/m,熔点1200℃)。

力学性能:使用DR-507A型万能拉伸仪(东莞市东日仪器有限公司)对Al-氟橡胶3D打印样品的拉伸力学性能进行表征。样条长度2cm,拉伸速度10mm/s。

图2为不同液态金属改性Al的SEM图,结果表明,原料Al粉为粗糙的球型,而1%GLM-Al表面光滑完整但仍为球形。随着液态金属含量增加,Al颗粒逐渐开裂,出现爆米花状形状,如图2(c)所示; 7%GLM改性铝粉碎裂为5~10μm颗粒,见图2(e)。

原因是由于Ga和Al都属于IIIA族元素,很容易形成固溶体,当镓润湿铝的表面后,镓原子会自发扩散并沿着Al晶界分布,并且当大量原子相互扩散时会出现细小的裂纹,再经过磁力搅拌和超声促使GLM-Al颗粒进一步碎裂[16]。

对3%GLM-Al进行EDS mapping测试(见图 3),结果表明,Ga、In和Sn元素均匀地分布在Al颗粒表面。裂缝处Al元素较多,几乎没有O元素,表明Al和液态金属的相互作用可以抑制Al表面Al2O3壳的形成[20],且液态金属的脆化作用已将Al颗粒表面的Al2O3破坏。

利用X射线光电子能谱进一步对3%GLM-Al表面的价态进行分析,结果见图4。图4(a)表明GLM-Al样品含有Ga、In、Sn、Al和O。因为Al和液态金属易氧化故仍可以检测到氧元素。图4(b)中,GLM-Al的Al 2p光谱分裂成两个峰,这两个峰分别位于72.2和74.5eV,表明存在Al和Al2O3[20]。图4(c)显示了与Ga和Ga2O3[21]对应一致的Ga 2p两个不同的峰(Ga 2p3/2和Ga3+2p3/2)。图4(d)显示了GLM-Al的In 3d光谱,观察到4个峰(In 3d3/2、In3+d3/2、In3dX5/2和In3+3d5/2),这是由于自旋轨道耦合和In氧化。图4(e)显示了GLM-Al的Sn 3d光谱,类似于上述In 3d。以上结果表明分布在Al颗粒表面的Ga-In-Sn液态金属及其氧化物和铝及其氧化物在Al颗粒表面形成了一个复合氧化层。

实验测得1%GLM-Al、3%GLM-Al、5%GLM-Al和7%GLM-Al的比表面积分别为0.98、3.48、2.86、2.03m2/g,表明随着液态金属含量的增加,由于Al颗粒出现爆米花的形状转变,比表面积先逐渐增大, 3%GLM-Al的比表面积达到最大值3.48m2/g,是原料Al(0.18m2/g)比表面积的19.3倍,继续增加液态金属含量,GLM-Al的比表面积逐渐减少,这与图2中Al粉的SEM结果相一致。

通过DSC-TG研究了液态金属含量对GLM-Al热氧化性能的影响,结果如图5和表1所示。

由图5和表1可知,GLM-Al在热氧化过程中有一个吸热峰和一个放热峰。其中,660℃吸热峰是原料Al粉或GLM-Al熔化吸热产生,且液态金属改性后吸热量明显降低,说明液态金属破坏了Al表面的Al2O3壳进入其内部,使吸热量降低,熔点也降低。液态金属质量分数为1%、3%、5%和7%的GLM-Al放热峰分别为992.3、1008.9、1003.9和1000.1℃,明显低于原料Al放热峰温度(1039.2℃)。而且改性后热氧化放热量明显增加,当液态金属质量分数从1%增加到7%时,放热量先增加后减小。当液态金属质量分数为3%时,放热量最高为6181J/g,氧化增重为42.92%,均为原料Al的3.5倍(1785J/g,12.31%)。主要原因是液态金属破坏了Al的Al2O3壳(图2)和比表面积明显增大(图3),导致Al热氧化反应更加充分。

图6为原料Al和3% GLM-Al及其热氧化反应产物的XRD图。GLM-Al的XRD图谱中,只观察到In和Al的特征衍射峰,表明GLM中的Ga和In在与原料Al混合过程中发生了分离。Ga和Al同属于IIIA族元素,因此它们很容易形成固溶体[22],但In和Sn在Al中的固体溶解度几乎为零。所以,当GLM接触Al时,会发生相分离,Ga会进入Al颗粒内部而In和Sn则会停留在颗粒表面[18]。与原料Al的氧化产物相比,GLM-Al氧化产物的Al2O3衍射峰强度大大增加,Al衍射峰强度大大降低,表明GLM-Al的氧化更加完全。所以选择3%GLM-Al作为燃料加入到F2311中进行后续实验是最佳选择。

图7是改性前后20℃和80℃Al-氟聚物黏度随剪切速率的关系图。此处的Al-氟聚物当量比均为3.5。20℃时,将黏度变化分为两个区域,区域Ⅰ(0.1~20s-1)是低剪切速率区,在该区域,改性前后Al-氟聚物墨水黏度随着剪切速率增加均急剧降低,被认为是典型的非牛顿流体。由于这种剪切变稀特性,使墨水可以顺利通过3D打印针头。区域Ⅱ(>20s-1)即高剪切速率区,也称为牛顿区,墨水黏度下降且基本保持不变,利于墨水稳定挤出。在0.1~100s-1剪切速率范围内,GLM-Al-氟聚物墨水黏度均略高于原料Al-氟聚物。80℃时,黏度变化可以分为3个区域,区域Ⅰ'(0.1~1.6s-1)墨水黏度几乎不随剪切速率变化,区域Ⅰ″(1.6~20s-1)此时墨水黏度随着剪切速率增加缓慢降低,而剪切速率继续增加到区域Ⅱ(>20s-1)时墨水黏度几乎不随剪切速率变化。

图8是改性前后Al-氟聚物复合反应性材料3D打印样品的宏观和微观形貌结果。

由图8(a)可知,宏观上样品形貌规则,粗细均匀,尺寸10cm×0.1cm×0.4cm。图8(b)为GLM-Al-氟聚物横截面微观结构,结果显示横截面无裂纹,层间无界面。

进一步放大,如图8(c)所示,爆米花状的GLM-Al颗粒均匀分布在氟聚物基体中,并且结合紧密,说明F2311作为黏结剂可以有效防止裂纹产生,在保证Al颗粒高负载的同时又具有很好的黏结紧密性,其粒径与图2(c)结果一致。图8(d)为原料Al-氟聚物横截面SEM图,进一步说明仅经过机械搅拌并不会使原料Al的Al2O3壳破裂。

不同当量比和液态金属含量的GLM-Al-氟聚物的燃烧过程和结果如图9和表2所示。

由于3%液态金属改性的GLM-Al热氧化放热量最大(见表1),所以首先研究了3%液态金属改性时不同当量比的Al-氟聚物燃烧过程。由表2结果表明:当量比为2.0时,GLM-Al-氟聚物可以点燃但不能持续燃烧。当量比为2.5~5.0时,均持续燃烧,燃速先增加后减小; 当量比为3.5时,燃速最大为6.0mm/s。但是火焰面积随当量比增加而增加,且当量比为5.0时,火焰面积最大为16.6cm2,这是因为当量比为5.0时,Al粉堆积最多,Al粉传质距离最短,所以火焰面积大,但由于氧化剂不足,导致燃烧速度降低。

进一步研究了当量比3.5时,改性前和液态金属质量分数从1%增加到7%时燃速和最大火焰面积的变化规律,结果表明未改性的原料Al-氟聚物不能点燃,液态金属改性后Al-氟聚物的燃烧性能改善明显,1%GLM-Al-氟聚物可以点燃,但不能持续燃烧,3%~7%GLM-Al-氟聚物均可以持续燃烧,而且燃速增加,但是火焰面积减小。这是因为在原料Al和液态金属机械混合过程中,Al表面的氧化壳被破坏并出现了爆米花状的形状转变,导致Al颗粒和氟聚物的接触面积增大且活性Al容易释放出来。而且Al和液态金属的相互作用可以抑制Al表面Al2O3壳的形成,改善体系的能量释放。

(1)通过镓基液态金属改性制备了一种反应性增加的液态金属改性微米铝粉。与原料Al粉相比,液态金属改性后GLM-Al的热氧化反应更加完全,且随着液态金属含量的增加,热氧化放热量呈现先增加后减小的趋势。液态金属质量分数为3%时,GLM-Al热氧化放热量最大,为6181J/g,是原料Al粉的3.5倍。

(2)3D打印获得的GLM-Al-氟聚物复合含能材料燃烧性能显著改善。未改性的原料Al-氟聚物不能被点燃,液态金属改性后可以点燃且可以持续燃烧,在液态金属质量分数为3%、当量比为3.5时,燃烧速度最大为6.0mm/s; 火焰面积随当量比增加而增大,且当量比为5.0时,火焰面积最大为16.6cm2。

(3)铝粉通过液态金属改性后提高了GLM-Al-氟聚物复合含能材料的拉伸力学性能。随着液态金属含量增加,当量比为3.5时,GLM-Al-氟聚物抗拉强度和断裂伸长率均先增加后减小, 3%GLM-Al-氟聚物的抗拉强度和断裂伸长率均最大,分别为1.73MPa、11486%,是原料Al-氟聚物的1.5倍和1.3倍。