作者简介:王书记(1992-),男,博士研究生。E-mail:3120195142@bit.edu.cn

通信作者:郭学永(1975-),男,研究员。E-mail:nust@bit.edu.cn

(1.北京理工大学 爆炸科学与技术国家重点实验室,北京 100081; 2.重庆红宇精密工业有限责任公司,重庆 402760)

(1.State Key Laboratory of Explosion Science and Technology, Beijing Institute of Technology, Beijing 100081, China; 2.Chongqing Hongyu Precision Industrial Co. Ltd., Chongqing 402760, China)

physical chemistry; HATO; TKX-50; solubility; recrystallization; thermal stability; mechanical sensitivity

DOI: 10.14077/j.issn.1007-7812.202303010

1,1'-二羟基-5,5'-联四唑二羟胺盐(HATO,又称TKX-50)自2012年由Fischer团队[1]首次报道合成以来,便因其“高能量、低感度”的特性成为近年来最具应用前景的新型含能材料之一,引起国内外众多研究者的关注。通过EXPLO5.05软件计算得到HATO的爆速为9698m/s、爆压为42.4GPa、撞击感度为20J、摩擦感度为120N,爆炸性能接近CL-20,撞击感度显著低于RDX,在火炸药领域具有巨大的应用潜力[2-3]。

单质炸药的种类不仅影响混合炸药的爆炸性能,其粒度、形貌、晶体缺陷更是直接影响混合炸药体系的安全性、成型性及力学性能[4-6]。直接合成得到的HATO晶体纯度较低且形貌极不规则,限制了其在混合炸药中的应用[7-8]。因此,通过晶体改性处理,制备形状规则、球形或类球形、表面光滑、流散性好的高品质HATO晶体,对提升其在含能材料领域中的应用具有重要意义。

国外关于HATO的研究主要集中在合成工艺[9]、热安定性[10-12]、爆炸性能[13-14]等方面,而关于HATO晶体改性的研究却鲜有报道。国内针对HATO晶体改性已开展大量研究[15]。任晓婷等[16]通过MS软件对HATO的晶体形态及结晶习性进行了模拟,并选择分子结构中含有富电子芳环的离子型表面活性剂制备出晶体形貌明显改善的HATO晶体; 米向超等[17]采用4种不同重结晶方法对HATO结晶过程进行研究,获得基本为片状的HATO晶体; 米登峰等[18]采用冷却结晶结合超声辅助法研究了不同工艺参数对HATO晶体形貌的影响,在丙酮与DMSO混合溶剂中制备出类球形HATO晶体; 周畅[19]研究了不同添加剂对HATO形貌的影响,得到了几组形貌较好的结晶体系; 李丹[20]、许鑫[21]、马凤利[22]等测量了HATO在不同溶剂体系中的溶解度,通过优选重结晶溶剂体系,制备出不同形貌的HATO晶体。但还是存在HATO晶体粒度较小、粒径分布不均,晶体球形度低,仍有较多的棱角,且工艺相对复杂,所用溶剂不易处理等问题。

本研究采用降温重结晶的方法,在优选的溶剂体系中,通过结晶工艺参数控制制备出高品质HATO晶体,并对其性能进行表征。探究了溶剂种类、降温速率、搅拌速率对HATO晶体形貌的影响。同时本实验方法具有溶剂体系无毒、结晶过程简单可控、工艺放大可行等优点。获得的高品质HATO晶体对于降低混合炸药感度、提升装药的不敏感性具有重要意义。

HATO,西安近代化学研究所; 蒸馏水,实验室自制; 甲酸、乙酸、乙醇、乙酸乙酯,均为分析纯,北京市通广精细化工公司; F2603型氟橡胶、Estane5702,中蓝晨光化工研究设计院有限公司; 顺式1,4-聚丁二烯橡胶(BR),工业级,锦州石化股份有限公司; 三元乙丙橡胶(EPDM),工业级,中国石油天然气股份有限公司吉林石化分公司。

SYP型超级恒温水浴,巩义市予华仪器有限责任公司; AL104型电子天平,梅特勒-托利多仪器有限公司; Hitachi S-4700型扫描电子显微镜,日本日立公司; Bruker 400MHZ Advance核磁共振仪、Bruker Smart APEXCCD X射线衍射仪,德国布鲁克公司; Mastersizer 2000激光粒度分析仪,英国马尔文仪器有限公司; ZBL-B型撞击感度仪、BM-B型摩擦感度仪,西安近代化学研究所。

将过量的HATO加入到不同溶剂中,在20℃下搅拌12h,以确保固液平衡。停止搅拌,静置1h以上,然后过滤、烘干、称量,通过公式计算出HATO在不同溶剂中的溶解度。控制溶剂种类、降温速率、搅拌速率,制备得到高品质HATO晶体。

采用扫描电子显微镜对高品质HATO进行形貌分析,测试条件为:加速电压5.0kV,发射电流4.0μA。

采用红外光谱仪对高品质HATO进行结构表征。测试条件为:KBr压片,测试范围400~4000cm-1。

采用核磁共振仪对高品质HATO进行结构分析,测试条件为:内参比样氘代二甲基亚砜、硝基甲烷,共振频率400MHz。

采用激光粒度仪对重结晶后HATO粒度分布进行测试,测试条件为:无水乙醇作为分散剂。

采用差示扫描量热仪测试高品质HATO的热分解性能,测试条件为:升温速率10K/min,N2气氛,样品质量2.0mg。

依据GJB 772A-97《炸药试验方法》规定测试高品质HATO的性能参数。特性落高试验条件为:10kg落锤,50mg药量; 爆炸百分数测试条件为:10kg落锤,25cm落高,50mg药量; 摩擦感度测试条件为:90°摆角,20mg药量,3.92MPa表压; 爆速测试条件为:Φ40mm×40mm药柱,压药密度达理论密度95%。

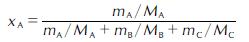

溶质的摩尔分数溶解度xA可采用下式计算,每组实验重复3次,取平均值。

式中:xA为摩尔分数; mA、mB、mC分别为溶质A、溶剂B和溶剂C的质量; MA、MB、MC分别为溶质和两种溶剂的分子量。

利用静态平衡法,在298.15 ~333.15K温度范围内,分别测试了HATO在4种纯溶剂(水、甲酸、乙酸、乙醇)及3种混合溶剂(水-甲酸,水-乙酸,水-乙醇)中的溶解度,不同溶剂体系中的溶解度曲线如图1和图2所示。

由图1可以看出,HATO在水、甲酸、乙酸和乙醇中的溶解度随温度的升高而增加。可以推断,HATO的溶解是一个吸热过程,温度的升高有利于向吸热方向的溶解平衡。在298.15~333.15K温度范围内,HATO在4种溶剂中的溶解度大小顺序为:甲酸>水>乙酸>乙醇。从溶解度对温度的依赖关系可知,采用冷却结晶法设计HATO的结晶过程,是一个更好的选择。

图2 HATO分别在水-甲酸、水-乙酸和水-乙醇混合体系中的溶解度

Fig.2 Solubility of HATO in ater-formic acid,water-acetic acid and water-ethanol

由图2可以看出,HATO的溶解度随温度的升高而增加。在水-甲酸混合溶剂中,HATO的溶解度随水的初始质量分数的增加而单调降低; 在水-乙酸和水-乙醇混合溶剂中,HATO的溶解度随水的初始质量分数的增加而单调增加。

选择水作为HATO结晶控制的溶剂,分别以甲酸、乙酸、乙醇作为副溶剂,与水形成二元混合溶剂,在一定温度下,将适量的HATO完全溶解,采用程序降温的方式研究重结晶工艺。研究过程中,以晶体球形度和粒度作为目标函数,以二元溶剂混合比例、降温速率、搅拌速率作为工艺影响因素,实验研究各因素对目标函数的影响规律。

HATO在溶剂中的溶解度越大,对其重结晶影响则越显著。溶剂体系中不同的溶剂分子与HATO晶体中各晶面的作用力不同,最终影响HATO的晶体形貌。在初温为60℃,自然降温的条件下,分别采用甲酸、乙酸、乙醇与水质量比均为1:9的混合溶液及纯水为溶剂,重结晶后得到的HATO晶体的显微镜照片如图3所示。

由图3(a)可以看出,以纯水为溶剂,重结晶得到的HATO晶体呈不规则片状结构,棱角较多; 由图3(b)可以看出,以水-甲酸混合溶液为溶剂,重结晶制得的HATO晶体呈棱柱状,且孪晶严重,粒径约为150μm; 由图3(c)可以看出,以水-乙酸混合溶液为溶剂,重结晶制得的HATO晶体呈长条薄片状,粒度不均匀; 由图3(d)可以看出,以水-乙醇混合溶液为溶剂,重结晶制得的HATO晶体结构呈类球形,棱角显著减少,粒径约为150μm。表明水-乙醇混合溶液体系更有助于HATO晶体的球形化生长,实验结果与仿真计算结果一致。

搅拌速率过低,细小的晶体容易形成聚晶。搅拌速率增加,有利于消除各晶面上过饱和度的差别,使晶形趋于球形; 搅拌速率过高则会使晶体碎裂,导致颗粒不规整。

在以水与乙醇( 质量比为9:1)的混合溶液为溶剂、自然冷却的条件下,搅拌速率分别为40、60、80、100、200、300r/min时,制得HATO样品,其偏光显微镜照片如图4所示。

实验研究发现,搅拌速率在0~100r/min区间内时,随着搅拌速率的提高,HATO晶体的粒度增大,d50由40r/min时的78μm增至100r/min时的325μm; 当搅拌速率大于100r/min时,随着搅拌速率的提高,HATO粒度减少,当搅拌速率为200r/min和300r/min时,样品的d50分别为140μm和130μm; 说明搅拌强度起主要作用,搅拌强度越大,碎裂的晶体越多,晶体粒度越小。

降温速率过快,有利于晶体球形化生长,但晶体粒径一般较小; 当降温速率过慢时,不同晶面的生长速度差别较大,得到的晶体多为片状、针状和板状等。

在水与乙醇( 质量比为9:1)的混合溶液为溶剂、搅拌速率为100r/min的条件下,分别采用快速降温(加入与混合溶剂质量相等的冰块)、中速降温(加入与混合溶剂质量相等的水)与慢速降温(室温20℃下自然冷却),制得 HATO样品,其偏光显微镜照片如图5所示。

由图5可见,快速降温时,HATO晶体细小,d50为130μm,晶体形貌不规整; 当采用中速降温时,d50为200μm,HATO晶体明显长大; 慢速降温时,d50为325μm,可以得到圆滑致密的高品质HATO晶体。

以DMSO-d6为溶剂,对HATO进行氢谱和碳谱的核磁共振表征,结果如图7所示。

由图7可知,1H NMR 谱图中的化学位移δ=9.56(8H,NH3OH); 13C NMR谱图中的化学位移δ=134.85。测试结果与文献报道结果较一致。

在升温速率10K/min下,原料HATO与高品质HATO的DSC曲线如图8所示。

由图8可知,高品质HATO的热分解峰温为247.9℃,较原料HATO的热分解峰温227.4℃提高了20.5℃。这是因为高品质HATO粒度较大,且球形度高、形貌好,晶体表面的棱角更少,在受热过程中更不容易形成热点,因此,热安定性有所提升。

高品质HATO的撞击感度为24%,较原料HATO的(42%)下降了18%; 摩擦感度为16%,较原料HATO的(36%)下降了20%。其原因是高品质HATO晶体球形度高,具有较好的流散性; 晶体形貌规整,晶体缺陷少,因而导致其机械感度显著降低。

依据相关标准对重结晶前后HATO进行测试,每组实验重复3次,结果见表1和表2。

通过对比发现,重结晶处理后的HATO各项性能均有所提升。

单质炸药在压装混合炸药中应用时往往需要进行包覆处理,以进一步降低其机械感度,同时改善药柱的成型性和力学性能。为优选出与HATO结合能力强的黏结剂材料,采用Materials Studio软件,以HATO的(0 2 0)晶面作为模拟计算对象,在Forcite模块下运用NVT系综下完成分子动力学模拟,得到HATO与几种黏结剂的内聚能密度和结合能。HATO与不同组分的平衡态结构如图9所示。

将建立好的HATO复合体系的模型进行MD模拟,采用Materials Studio软件中Forcite模块,模拟条件为PCFF力场,NVT系综,Andersen控温程序,温度298K,模拟时间为50ps,模拟步长为1fs,模拟完成后分析模型的势能和温度达到平衡稳定状态,按照上述模拟条件再次对平衡后的模型进行MD模拟,每500步保存一次轨迹文件,选取最后5ps的构象进行HATO复合体系结合能和内聚能密度的分析。通过计算得到HATO与不同材料的结合能及内聚能密度见表3。

表3 HATO与不同材料的结合能及内聚能密度

Table 3 Binding energy and cohesive energy density of HATO with different materials

由表3可知,6种不同材料与HATO的内聚能密度大小顺序为:PVDF > F2603 > Wax>BR>EPDM>Estane。由计算结果可以看出,含氟材料与HATO的内聚能密度大于非含氟材料,说明含氟黏结剂与主体炸药HATO的结合能优于非含氟高聚物黏结剂。

依据理论计算结果,选择几种常用黏结剂材料利用溶剂蒸发法分别对HATO进行包覆,并对包覆后HATO样品的感度进行了测试,不同材料包覆后的HATO样品如图 10所示。

由图 10可以看出,不同材料包覆HATO样品的效果不同。F2603包覆HATO样品无肉眼可见的HATO裸露晶体,包覆紧密,成型性好; BR与EPDM包覆HATO样品有较多肉眼可见HATO裸露晶体,包覆效果较差。

依据GJB 772A-97相关实验标准对几种包覆的HATO样品的机械感度进行了测试,测试结果见表4。

表4 不同材料包覆HATO样品感度

Table 4 Mechanical sensitivities of HATO samples after coating with different materials

由表4可以看出,不同材料包覆后HATO样品的机械感度均小于未包覆HATO样品,其中微晶蜡表现出优异的降感效果。与微晶蜡相比,F2603密度更高,且可以与混合炸药中常用金属燃料发生反应,提高混合炸药体系的成型药柱密度与能量水平,对HATO基混合炸药黏结剂体系设计具有一定的指导意义。

(1)HATO的溶解度随温度的升高而增加,在298.15~333.15K温度范围内,HATO在4种溶剂中的溶解度大小顺序为:甲酸>水>乙酸>乙醇。

(2)采用降温重结晶方法,以水与乙醇(质量比为9:1)的混合溶液为溶剂,搅拌速率为100r/min,自然降温的条件下,可制得圆滑致密的高品质HATO晶体。高品质HATO晶体形貌规整,呈类球形,热安定性和感度均优于原料HATO。

(3)MS仿真计算表明含氟材料与HATO具有更高的黏附能力,可以更好地包覆HATO晶体,实验结果与理论计算结果一致。