作者简介:仝志珂(1999-),男,硕士研究生。E-mail:Victor_Tong895@qq.com 通信作者:李永祥(1964-),男,教授。E-mail:liyongxiang@nuc.edu.cn

(1.中北大学 化学与化工学院,山西 太原 030051; 2.湖北东方化工有限公司,湖北 襄阳 441400; 3.山西江阳化工有限公司,山西 太原 030051)

(1.School of Chemistry and Chemical Engineering, North University of China, Taiyuan 030051, China; 2.Hubei Dongfang Chemical Co., Ltd, Xiangyang Hubei 441400, China; 3.Shanxi Jiangyang Chemical Co., Ltd., Taiyuan 030051, China)

organic chemistry; melt-cast carrier explosive; 3-nitropyrazole; hydrothermal method; thermal rearrangement; nitrogen heterocyclic compounds

DOI: 10.14077/j.issn.1007-7812.202304016

备注

作者简介:仝志珂(1999-),男,硕士研究生。E-mail:Victor_Tong895@qq.com 通信作者:李永祥(1964-),男,教授。E-mail:liyongxiang@nuc.edu.cn

引言

熔铸炸药是一类在熔化后的液相载体炸药(如TNT)中加入固相高能主炸药(如RDX、HMX等),再固化成型的混合炸药,这类炸药在军用混合炸药中能占到90%[1]。2,4,6-三硝基甲苯(TNT)作为传统的熔铸炸药载体存在渗油、收缩和膨胀等缺点,且污染物会对环境造成严重威胁[2-3]。因此寻找新的可替代TNT的熔铸炸药载体成为现在的热点。

氮杂环化合物具有能量高、密度高且更易达到氧平衡等特点[4],已经成为近年来含能化合物的研究热点。3-硝基吡唑(3-NP)作为典型的氮杂环化合物,是合成3,4-二硝基吡唑(DNP)等新型熔铸炸药载体的重要中间产物。Jassen等[5]在1973年首次通过3-NP硝化得到DNP后,拉开了人们以吡唑为原料合成出N-硝基吡唑(N-NP)、然后N-NP热重排得到3-NP再硝化得到DNP的三步法研究的序幕。

国内合成3-NP的方法主要是首先通过将吡唑硝化得到N-硝基吡唑(N-NP),然后将N-NP在苯甲醚、苯甲腈、正辛醇等高沸点有机溶剂中重排得到3-NP[5-7]。但是由于原料N-NP易升华以及这些高沸点溶剂存在毒性大、价格昂贵、反应时间较长、得率较低以及在重排反应过程中有副产物生成等问题,因此寻找合适的重排方法成为含能材料研究者的首要关注点。

水热法是通过使用高温、高压水溶液将平时难溶或不溶的物质溶解和重结晶,已被广泛应用于材料制备、化学反应和处理领域[8]。2015年刘威等[9]以吡唑为原材料,经过发烟硝酸和酸酐体系硝化后直接将反应液转移至水热釜中,在170℃下高压反应3h,一锅两步法合成了3-NP,得率为46.2%。此方法中发烟硝酸和酸酐体系在水热釜中存在着极大的安全隐患同时得率极低。2022年藤依依等[10]通过将N-NP和1,2-二氯乙烷投入高压釜中,在180℃下高压反应4.5h后加入适量正己烷分散,除去溶剂,干燥得到3-NP,得率为95%。该方法中1,2-二氯乙烷属于2B类致癌物且后处理较为麻烦。

本研究采用水热釜作为反应容器,二甲苯作为热重排溶剂,取代原工艺中的苯甲腈、苯甲醚、正辛醇、1,2-二氯乙烷等有机溶剂。通过一系列单因素实验探索出较佳的工艺条件,N-NP在该条件下可直接重排得到粗品纯度大于99%的3-NP。

1 实 验

1.1 试剂与仪器N-硝基吡唑(N-NP),自制; 冰乙酸(CH3COOH),西陇科学股份有限公司; 溴苯、二甲苯、邻二氯苯,上海阿拉丁生化科技股份有限公司。

25mL水热合成反应釜; FZG-15型真空干燥箱,南京铭瑞科技有限公司; FL2200-2型高效液相色谱仪,江苏福立分析仪器有限公司; M-565型熔点仪,印度 BUCHI公司; NICOLET 5700型傅里叶红外光谱仪,美国尼高力仪器公司。

1.2 3-硝基吡唑的合成以N-NP为原料,3-NP合成路线如图1所示。

取1.0g N-NP加入到25mL的水热釜中,然后加入3mL二甲苯,密闭水热釜并放置油浴烘箱中,升温至180℃,保温反应3h,反应完成后自然冷却至室温,打开密闭水热釜将反应液过滤后可直接获得浅白色3-NP,得率为100%。熔点175.3~176.1℃(文献[11]报道174~175℃),纯度(HPLC:乙腈与0.1%乙酸水体积比为35:65)99.76%

IR(KBr,cm-1):3142(N—H),1554、1209(C—NO2)。

2 结果与讨论

3 结 论

(1)通过使用密闭的水热釜避免了N-硝基吡唑的升华现象,使得重排得率达到100%。

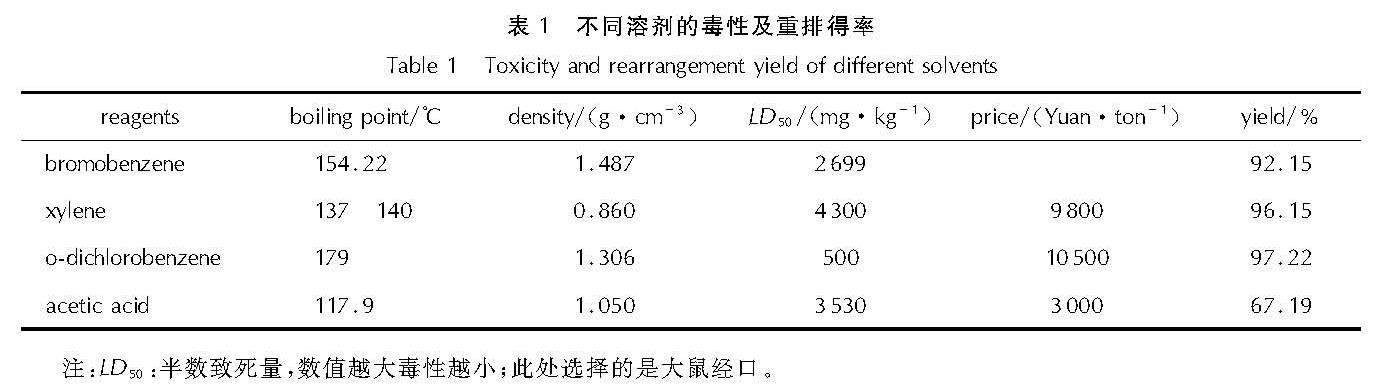

(2)在几种备选的重排溶剂中通过毒性、固液比等因素确定了二甲苯为较佳的重排溶剂。

(3)通过对反应温度、时间、填充度及计算压力的研究,最终确定二甲苯水热法较佳的反应条件为:在固液比为1g N-NP: 3mL二甲苯,填充度为15%,理论压力在6.130MPa左右,反应温度为180℃下保温3h时,3-NP重排得率为100%。

(4)水热法合成3-硝基吡唑虽然有较高得率,但是当放大到工业化高压反应设备中得率有可能会降低,且高压反应在工业生产中具有一定的风险。文中展示的水热釜内压力计算与实际压力可能存在偏差,还需使用带压力显示的反应釜进行进一步实验对比。

2.1 重排机理N-硝基吡唑的热重排过程在二甲苯中进行,其热重排机制是一个两步的过程,包含两个转变状态和一个中间体,即硝基的[1,5]σ重排和中间体3H-吡唑的快速重排,重排机理如图2所示。

在整个反应过程中,硝基和相邻碳原子上的氢原子是主要的反应基团。硝基是从反应物到中间体过程的主要变体。在重排最初,硝基的迁移伴随着本体的扭动,使得过渡态硝基平面几乎垂直于吡唑环平面,随后硝基从中间产物到产物阶段不再有明显的变化。从中间阶段到产物阶段的变化主要是由氢原子的迁移和硝基平面与吡唑环平面夹角的变化引起。在过渡态中,氢原子几乎在碳原子与相邻氮原子连线的平分线上导致其不再是碳原子独有的。在氢原子迁移的过程中,硝基平面与吡唑环平面的夹角逐渐减小,而吡唑环角N(1)—N(2)—C(3)和C(4)—C(5)—N(1)呈增大趋势,C(5)—N(1)—N(2)、N(2)—C(3)—C(4)和C(3)—C(4)—C(5)呈下降趋势。

2.2 重排溶剂的选择及固液比对得率的影响2.2.1 重排溶剂的选择本研究选择一种环保溶剂来取代原高沸点溶剂作为热重排溶剂以及通过水热法提高得率,减少后处理步骤。

溶剂选择的基本原则:性质稳定,溶剂不与原料发生化学反应; 毒性较低; 价格便宜; 后处理方便,易除去。据此筛选出符合条件的几种不同溶剂,通过水热法在相同反应温度、时间及料比下,不同溶剂的毒性及重排得率比较如表1所示。

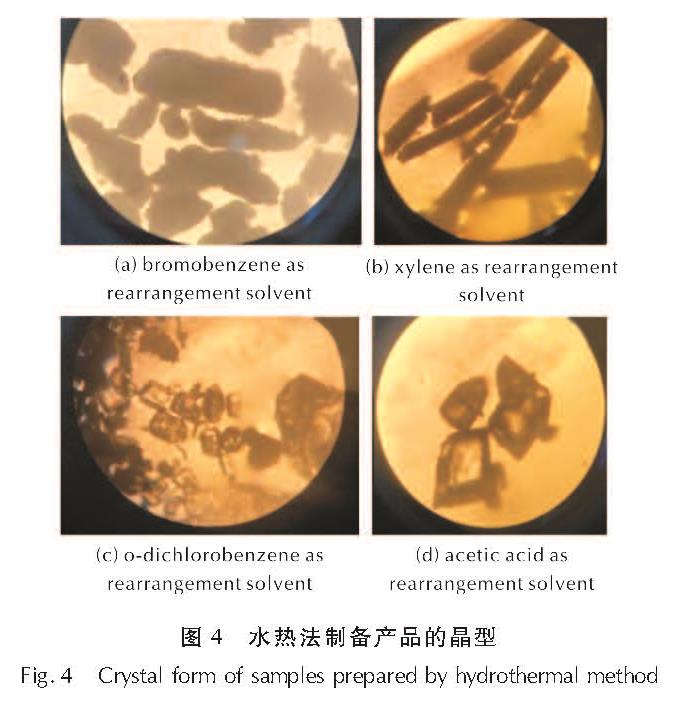

由表1可知,在相同的反应条件下,溴苯、二甲苯、邻二氯苯和乙酸作为重排溶剂3-NP的得率分别为92.15%、96.15%、97.22%和67.19%; 其中乙酸作为重排溶剂的表现不佳,其他3种溶剂得率相差不大。经过溶剂毒性的对比,二甲苯相比于溴苯及邻二氯苯毒性最小。

2.2.2 固液比对得率的影响文献[5]报道的N-NP与苯甲腈的固液比为1g:10mL,3-NP得率为92%,文献[10]报道的N-NP与1,2-二氯乙烷的固液比为1g:10mL,3-NP得率为95%,而本研究中选择不同溶剂的固液比均在1g:5mL以下,极大减少了溶剂用量。不同溶剂固液比对反应得率的影响如表2所示。

由表2可以看出,当固液比为1:1、1:2时二甲苯和邻二氯苯作为重排溶剂时3-NP得率相对于溴苯和乙酸较好,但是当固液比为1:3、1:4、1:5时溴苯、二甲苯、邻二氯苯作为重排溶剂的得率均可达到100%。综合毒性、固液比最终认为二甲苯为较佳重排溶剂。

以上结果表明:以二甲苯重排溶剂在水热法中固液比(N-NP(g):二甲苯(mL))≥1:3时3-NP得率均达到100%。相比于已报道的文献[5,10],本研究大大节约了溶剂成本。

从理论上分析高压反应不仅可以加快分子的传质和碰撞从而加快反应速率,而且还会改变热力学的化学平衡。该反应为[1,5]σ重排反应,反应体系中只有单一物质N-硝基吡唑,反应机理是吡唑环中N—NO2的—NO2是不稳定基团,发生了—NO2的吡唑环分子内的迁移,未有外来反应原料导致的副产物形成,N-硝基吡唑完全转化为3-硝基吡唑。

2.3 反应温度对3-硝基吡唑得率的影响用二甲苯作为重排溶剂,在反应时间为3h时,反应温度对3-硝基吡唑得率的影响如表3所示。

表3结果表明:反应时间为3h,反应温度低于180℃时,温度不能提供足够的能量来支撑热重排反应,故反应温度降低,得率也明显下降。当反应温度为190℃时重排得率与180℃时相同,因此较佳的反应温度为180℃。

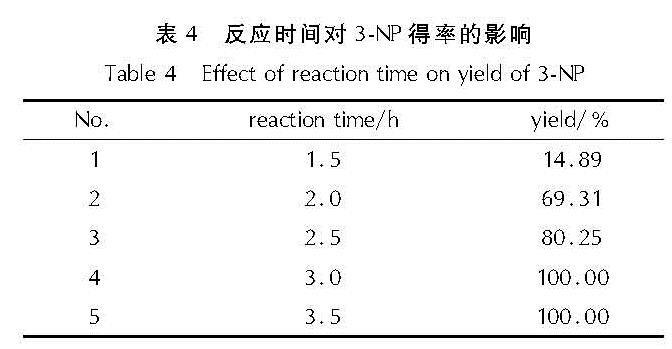

2.4 反应时间对3-硝基吡唑得率的影响用二甲苯作为重排溶剂,在反应温度为180℃时,反应时间对3-硝基吡唑得率的影响如表4所示。

表4结果表明,减少反应时间并不能得到较好的反应得率,较佳反应时间为3h。

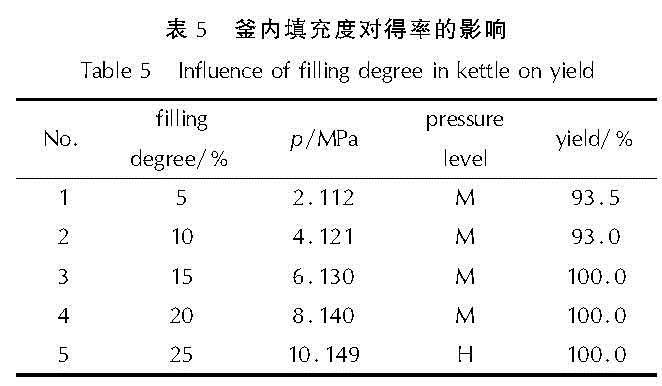

2.5 水热釜填充度及压力对3-NP得率的影响2.5.1 水热釜内压力计算[14]

填充度是指反应物占密闭反应釜空间体积的百分数。填充度是一个重要因素[15]。本研究采用理想气体方程与水热釜填充度、溶剂密度和反应温度对水热釜内的压力进行计算。水热釜结构见图3,水热釜高度为117mm,直径为57mm; 聚四氟乙烯内胆直径为40mm; 下垫片为27mm; 内胆体积为25mL。

本研究水热釜中的反应液为二甲苯且反应过程中不会生成气体,因此,在水热过程中仅依靠二甲苯蒸汽产生的压力对反应过程施压。

已知二甲苯密度ρ为0.86g/cm3,纯度C1为99%,二甲苯的摩尔质量M为106.17,标准大气压状态下(P0=0.1MPa,T0=273.15K),水热釜内胆溶剂V为25mL,加入反应液量与整个内胆的比例为填充度参数,用φ1 表示。

其中二甲苯添加的比例K为1,物质的量为n1,釜中初始的气体体积V0为5mL,加热生成蒸气的物质的量为n'0。

根据化学关系式可得n1值:

加热前混合理想气体方程:

p0V0=n0RT0(2)

加热后,釜内温度逐渐升高,最终达到180℃时,绝对温度为T1,混合理想气体方程为:

p1V0=n'0RT1(3)

n'0=n0+n1(4)

式中:V0为内衬里气体的体积,L; P1为升温后釜内压力; R为理想气体常数,8.314J/(mol·K); n'0、n0为反应前后内衬里气体的物质的量,mol。

联合公式(1)~(4)可得到釜内压力P1的计算公式:

2.5.2 水热釜填充度及压力对反应得率的影响

2.5.2 水热釜填充度及压力对反应得率的影响根据《压力管道设计单位资格认证与管理办法》可知压力的分布情况:压力范围在0.1≤P<1.6MPa为低压; 压力范围在1.6≤P<10MPa为中压; 压力范围在10≤P<100MPa为高压; 压力≥100MPa时为超高压。采用公式(5)计算得到水热釜的压力和水热釜填充度对反应得率的影响,结果见表5。

由表5可知,当填充度为5%和10%时釜内理论压力为2.112MPa和4.121MPa,同时3-NP得率较低为93.5%和93.0%; 当填充度为20%和25%时釜内理论压力为8.140MPa和10.149MPa,同时3-NP得率为99.7%和100%; 当填充度为15%时釜内理论压力为6.130MPa,同时3-NP得率为100%,从经济的角度来讨论,当填充度为15%时釜内压力属于中压级别,同时3-NP得率较好。

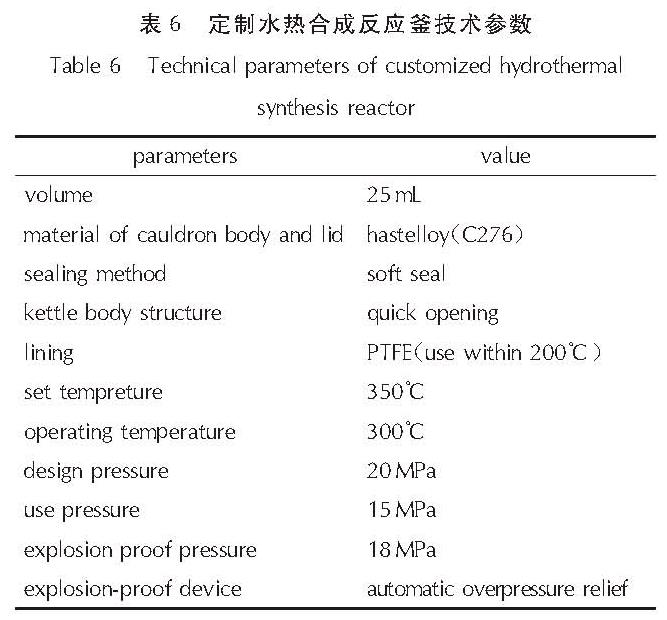

2.6 水热法合成的安全问题及分析高压不仅可以加快分子的传质和碰撞从而加快反应速率,而且还会改变热力学的化学平衡,因此保持一定的压力是有必要的。水热合成是一类特殊的合成技术,有诸多因素影响实验的安全和合成。在实验中既要保证反应物处于液相传质的反应状态,又要防止由于过大的填充度导致过高的压力从而引起爆炸[16-19]。本研究开展的热重排反应为液相反应且未有气体产物生成,它的重排工艺参数均符合所定制的水热合成反应釜的温度和压力参数,定制水热合成反应釜技术参数如表6所示。

由表3和表5计算可知,本研究所使用最高温度(190℃)和压力(10.149MPa),均小于表6中定制设备的使用温度和压力,并通过多次工艺优化实验均未发生安全问题。因此本研究采用水热反应开展研究是安全的。

- [1] 王亲会. 一种新型熔铸炸药研究[J]. 含能材料, 2004, 12(1): 46-47.

- [2]王亲会.熔铸混合炸药用载体炸药评述[J].火炸药学报,2011,34(5):25-28.

- [3]张秋越,孟子晖,肖小兵, 等. 用分子烙印聚合物吸附溶液中的TNT[J].火炸药学报,2007, 30(1):64-66.

- [4]CIEZAK J A, TREVINO S F. The inelastic neutron scattering spectra of α-3-amino-5-nitro-1,2,4-2H-triazole: Experiment and DFT calculations[J]. Chemical Physics Letters, 2005, 403(4-6): 329-333.

- [5]JANSSEN J W A M, KOENERS H J, KRUSE C G, et al. Pyrazoles. XII. Preparation of 3(5)-nitropyrazoles by thermal rearrangement of N-nitropyrazoles[J]. The Journal of Organic Chemistry, 1973, 38(10): 1777-1782.

- [6]李洪丽, 熊彬, 姜俊, 等. 3-硝基吡唑及其盐类的合成与表征[J]. 火炸药学报, 2008,31(2): 102-104.

- [7]李翠屏, 孙天旭, 陈新志. 3-硝基吡唑的合成[J]. 染料与染色, 2004(3): 168-169.

- [8]施尔畏, 夏长泰, 王步国, 等. 水热法的应用与发展[J]. 无机材料学报, 1996(2): 193-206.

- [9]刘威, 李永祥, 许元刚, 等. 一锅法合成3-硝基吡唑的研究[J]. 精细化工中间体, 2015, 45(5): 60-62.

- [10]滕依依, 张松, 侯静, 等. 高效连续化制备3,4-二硝基吡唑工艺研究[J]. 化学工程, 2022, 50(4): 52-57.

- [11]HABRAKEN C L, JANSSEN J W A M. Pyrazoles. VIII. Rearrangement of N-nitropyrazoles. Formation of 3-nitropyrazoles[J]. The Journal of Organic Chemistry, 1971, 36(21): 3081-3084.

- [12]JANSSEN J W A M, HABRAKEN C L, LOUW R. On the mechanism of the thermal N-nitropyrazole rearrangement. Evidence for a [1,5] sigmatropic nitro migration[J]. The Journal of Organic Chemistry, 1976, 41(10): 1758-1762.

- [13]FENG Y, YONG-XIANG L, XIN D, et al. Theoretical study on the transition state of N-nitropyrazoles rearrangement reaction[J]. Chinese J Struct Chem, 2018, 37(4): 12.

- [14]潘慧莹, 韩兴威, 张爱黎, 等. 水热反应釜使用过程中的危险性分析及安全评价[J]. 辽宁化工, 2021, 50(12): 1915-1918.

- [15]刘小华, 孙荣林. 水热与溶剂热合成技术在无机合成中的应用[J]. 盐湖研究, 2008, 16(2): 60-65.

- [16]周晓革. 水热合成反应釜爆炸失效原因分析及对策措施研究[D]. 广州:华南理工大学, 2018.

- [17]张佳新. 钙钛矿型La1-xSrxMnO3晶体形貌调控与低填充度水热合成的研究[D]. 长春: 吉林大学, 2017.

- [18]李艳辉. 微纳米结构氧化铝粉体合成与应用研究[D]. 广州: 华南理工大学, 2014

- [19]步明升. α-FeOOH与α-LiFeO2的水热合成研究[D]. 青岛: 中国海洋大学, 2010