基金项目:国家自然科学基金(No.21875184)

作者简介:张建侃(1992-),男,硕士,助理研究员。E-mail:zjk30120@zju.edu.com

通信作者:赵凤起(1963-),男,博士,博导,研究员。E-mail:zhaofqi@163.com

(西安近代化学研究所 燃烧与爆炸技术重点实验室,陕西 西安 710065)

(Science and Technology of Combustion and Explosion Laboratory, Xi'an Modern Chemistry Research Institute, Xi'an 710065, China)

solid propellant; Al-based alloy fuel; burning; metal fuel; aluminum; burning rate

DOI: 10.14077/j.issn.1007-7812.202203029

固体推进剂利用燃烧化学反应释放出的能量推动火箭武器的前进,是固体导弹发动机的动力源,其能量水平和燃烧性能与武器系统的作战使用效能密切相关。金属燃料的添加是提高推进剂能量水平的主要途径之一。金属燃料具有很高的质量热值和体积热值,其氧化反应的热值可达到TNT爆热的6~10倍; 同时,金属燃料的加入会降低推进剂配方的氧平衡,一定程度上降低燃气平均相对分子质量。因此,向推进剂配方中引入金属燃料可以提高配方能量、增加爆热和改善做功能力。另一方面,金属燃料的添加还会改变推进剂的燃烧性能,金属燃料的相变热对推进剂燃烧表面产生惰性热稀释[1],金属燃料燃烧释能对燃面进行热反馈[2],或金属燃料以单质或氧化态形式影响推进剂燃烧化学反应,上述因素会造成推进剂燃烧区物理化学环境的变化,从而导致推进剂的燃速发生改变。

金属燃料的理化性质由其微观结构和宏观形态决定,单质金属具有特定的元素组成和晶体结构,仅仅通过粒度分布和形貌等宏观形态的改变,对金属燃料性能调控的效果有限。近年来,武器装备技术的发展对固体推进剂的性能提出了多样化的要求,新型金属燃料的研发可以为获得更高能量密度、更高燃烧效率或更高燃速的推进剂奠定基础,从而满足不同应用背景的固体推进剂的性能需求。

合金燃料是将其他金属或非金属元素引入单质金属燃料中形成的多元金属燃料,其相组成可能是单相,也可能是包括固溶体合金和金属间化合物等多相的复合物,可以通过改变合金元素种类和添加量、制备工艺及参数,调控其相组成和相空间分布,使合金燃料具有可调的相变点、密度以及化学性质,进而在一定范围内优化合金燃料的点火和燃烧性能,例如铝基合金燃料取代铝粉后,可以改善铝粉点火延迟时间高的问题。合金燃料组成和理化性质多样化的特点,为固体推进剂的材料选择和性能调控提供了新的维度,是一种具有应用潜力的新型金属燃料。

本研究对几种不同类型铝基合金燃料的燃烧特性进行了系统梳理,分析比较了合金元素类型和相组成对其燃烧性能的影响规律,并从能量提升和燃速调控两方面综述了合金燃料在固体推进剂中的应用研究现状。

固体推进剂的燃烧由黏合剂、氧化剂和金属燃料等单一组分的燃烧及其相互作用组成[3],金属燃料在推进剂组分及其分解产物提供的化学环境中发生点火燃烧的同时,为氧化剂和黏合剂骨架的分解、氧化反应提供热环境以及催化作用[4]。因此,金属燃料的燃烧是推进剂燃烧反应的重要一环,其本征特性与推进剂性能密切相关。

铝元素是铝基合金燃料的重要成分,铝粉的α-Al相和Al2O3氧化膜也是多种铝基合金燃料的主要相组成,为了比较铝粉和铝基合金燃料的理化特征和燃烧特性,本节从铝粉的点火和燃烧出发,具体介绍了铝粉和铝基合金燃料的研究概况,分析了合金元素的添加对铝基合金燃料燃烧特性的影响,并总结不同类型合金燃料提高燃烧效率的机制和途径。

铝粉具有较高的体积热值和质量热值、耗氧量低、产物抑制不稳定燃烧和制取成本低等优势,是目前固体推进剂中应用最广泛的金属燃料; 然而其点火性能差、燃烧效率低和铝凝团加剧烧蚀等缺点限制了推进剂性能的进一步提升。铝粉燃烧效率偏低是由多方面因素导致的,由于铝具有较高的反应活性,在室温下就会形成一层无定型氧化膜,随着温度升高,无定型氧化膜最终转变为致密的α-Al2O3,阻碍了铝粉与氧化剂之间的反应,导致了铝粉点火温度高和点火延迟时间高[5]; 进一步地,由于铝粉的点火温度高于推进剂的燃面温度和铝的熔点,在含铝固体推进剂燃烧过程中,铝粉首先在燃面上发生熔融和团聚,随着燃面的退移,团聚铝颗粒逸出到燃烧区并发生点火[6],在此过程中,活性铝被团聚物包裹导致的不完全燃烧[7]、铝颗粒团聚长大造成的二相流损失[8]是造成推进剂能量性能降低的重要原因。此外,金属燃料在燃烧室中停留时间有限,铝粉较高的点火延迟会减少其反应时间,进一步降低能量释放的完全性和燃烧效率。

研究已经证实,铝粉的点火性能提升往往伴随着团聚程度的减轻和燃烧效率的提升[9-10]。点火的发生需要突破氧化层对氧化的阻碍作用,研究人员通过扩散反应机理解释了铝粉与不同氧化剂反应时[11]、铝粉不同氧化层厚度时[12]氧化剂迁移速率不同导致的点火燃烧性能差异,通过熔散反应机理[13-14]解释了高升温速率下纳米铝极高的燃烧速率[15]。虽然上述机理受限于适用范围,但相关研究对应的实验均证实了铝核的熔点、蒸气压及氧化膜厚度、结构、晶型等物化性质与铝粉的点火、燃烧性能密切相关。

针对铝粉的点火和燃烧性能提升的需求,国内外对纳米化、片状化和多孔化等宏观形态的改性方式开展了大量研究。俄罗斯和美国先后使用电爆炸法制备的纳米铝粉具有更低的点火延迟和点火温度[16-17],片状化铝粉具有比纳米铝更低的点火温度和更高的反应活性[18],多孔铝粉可以降低点火延迟从而减小团聚物尺寸[10]。然而,纳米铝粉和片状铝粉在活性提升的同时也伴随着活性铝含量的降低、在药浆中难以分散、流变性差[19-20]、推进剂成型后力学性能降低[21-22]等问题,多孔铝则会导致推进剂密度的下降。包覆和表面改性在一定程度上改善纳米铝粉的氧化以及分散性、流变性问题,但是包覆或改性材料的加入会造成活性铝含量的降低; 片状铝粉在气流中的聚集使其燃烧性能下降,燃烧完全程度和火焰传播速度均低于球形铝粉[23]。

合金化是除粒度与形貌控制以外对铝粉燃料进行活化的另一种有效方法。铝的合金化可以降低空化压力,使氧化壳的破裂和熔散反应更容易发生,从而改善燃料的点火性能[13]。根据燃烧波温度判断的固体推进剂燃面上的暗区温度可达1500℃,发光火焰区可达到的温度为2000℃以上[24],根据金属燃料在燃面上是否发生气化,可将金属单质分为低沸点金属(沸点低于1500℃,Low-Boiling point Metal, MLB)和高沸点金属; 根据金属燃料在发光火焰区是否熔化,可将金属单质分为高沸点低熔点金属(沸点高于1500℃且熔点低于2000℃)和高沸点高熔点金属(熔点高于2000℃),文中分别将其简称为低熔点金属(Low-Melting point Metal, MLM)和高熔点金属(High-Melting point Metal, MHM)(见表1)。3类金属在铝基合金燃料的燃烧过程中作用机制有明显区别,以下分别对Al-MLB合金、Al-MLM合金和Al-MHM合金3类铝基合金的研究现状进行介绍。

将低沸点的金属与铝形成合金燃料,一方面金属在燃烧过程中发生气相氧化,阻碍氧化膜的形成; 另一方面如Li和Mg等低沸点金属的氧化物致密度低,孔隙率较高[25],即使形成氧化物壳层也难以阻碍氧化剂的传输与燃烧反应的深入,因此具有比铝更低的点火温度和更快的燃烧速率; 此外Zn或Bi的氧化物可以降低含能化合物热分解的活化能[26-27],可以赋予铝基合金燃料一定的催化活性。

(1)Al-Li合金

虽然Li的化学性质非常活泼,但是Al-Li合金锂含量较低时,锂会以固溶的形式溶解在铝的内部,不会改变铝本身的相结构和致密氧化膜的形成,具有较高的抗氧化能力; 而锂含量的增加会导致Al-Li中间合金相的析出,提高对于水、氧的敏感性[28]。

Terry等[29]将Al-Li合金作为绿色推进剂的燃料进行了探索,利用Li的高反应性对推进剂尾气中的Cl-进行吸附,可以降低排气尾流中HCl含量及其对发射平台和臭氧层的破坏程度,以及减少不利于制导和隐蔽的二次烟的形成,但未对推进剂的组分相容性、存储性能和安全性进行说明。此外,研究人员还观察发现Al-Li合金在推进剂燃烧表面的微爆(Microexplosions)和分散沸腾现象(Dispersive boiling)(见图1),该现象可以有效避免Al-Li合金在燃面上的团聚并提高燃烧效率[30]。Jiao等[31]采用离心雾化法获得了不同Li含量的Al-Li合金,研究合金的微观结构发现颗粒内部由于制备过程中的高速降温形成了均匀的枝晶结构,颗粒表面则由α-Al/Al-Li金属间化合物组成的网状结构和填充在内的α-Al板片组成,网状结构中Al和Li之间较大的沸点差异使Al-Li合金具有微爆燃烧特性和更高的热氧化放热率,同时可以显著提高与高氯酸钾的反应活性和点火性能。

(2)Al-Mg合金

Mg的质量热值比Al低约20%,单位质量耗氧量比Al低约25%,在与单位质量的氧元素反应时,Mg的放热量甚至高于Al,可以提升推进剂的理论爆热,使Al-Mg合金成为了固体推进剂中最重要的活性合金燃料之一。

Dreizin团队的Shoshin、Umbrajkar和Schoenitz等[32-36]系统研究了Al-Mg机械化合金的微观结构及其对点火和燃烧性能的影响,并探索了Al-Mg合金燃烧的可能机理。研究人员通过机械合金化法制备了Mg质量分数为10%~50%的Al-Mg合金,主要由Mg溶解在α-Al相的固溶体和γ-Al12Mg17相组成,其中的亚稳相在退火过程中形成β相和新的γ相[32],氧化过程具有比Al更低的反应温度[33]。当Mg质量分数仅为10%时,合金燃料的点火温度就从纯铝的2300K降低到了1170K,随着Mg质量分数的增大,点火温度持续下降,但是合金的密度也有所降低; 当Mg质量分数达到30%时,合金燃料悬浮颗粒的火焰传播速率比纯铝高3倍,并且其火焰温度和火焰强度均高于原料Al粉,出现了明显的爆炸式点火(Explosive ignition)。此外,Al-Mg合金的燃烧效率亦高于纯铝,其燃烧产物中只含有铝与镁的氧化物和氮氧化物,而纯铝粉燃烧后仍有未反应的单质铝[34]。除机械化合金外,熔炼-气雾化也是一种铝基合金燃料的重要制备方法,相对于平衡凝固过程,气雾化具有较高的冷却速度,更容易形成亚稳相合金。通过熔炼-雾化法制备Al-Mg合金时,随着Mg质量分数的提高,Al-Mg合金的相组成由α-Al向β-Al3Mg2和γ-Al12Mg17转变,同时热氧化温度提前、氧化反应速率和反应热增加; Mg质量分数提升至50%时具有最低的点火延迟时间,而且燃烧模式由微爆向气相燃烧转变[37](见图2和图3)。

图2 Al-Mg合金在推进剂燃面的微爆现象

Fig.2 Microscopic images of microexplosion of Al-Mg alloy on the burning surface of the propellant

Feng等[38]开展了Al-Mg气雾化合金在预混平面火焰燃烧器中的燃烧行为和性能研究。研究人员观测到了微爆过程的3种典型现象:根据火焰光谱分析,微爆发生后,合金颗粒周围的气态火焰为镁蒸汽火焰,镁蒸汽均匀地向各个方向突破氧化膜向外喷射时,出现典型的微爆现象; 镁蒸汽从合金颗粒表面径向喷射或切向喷射时,合金颗粒改变其轨迹或旋转的现象分别称为金属蒸汽喷发(Metal vapor erupting)和合金粒子旋转(Alloy particle rotating)(见图4)。

此外研究人员考察了燃烧环境温度、燃烧气氛氧含量和Al-Mg合金粒径对点火和燃烧时间特性的影响规律[38]。点火延迟时间、燃烧持续时间和总时间(文中定义为点火延迟时间与燃烧持续时间之和)均随颗粒直径呈线性增加。由于氧化膜对氧化剂传输和热量传递的阻隔作用,在氧化性较强的环境中,合金颗粒的点火延迟时间延长; 相反地,点火发生后,更高的氧化剂含量使Al-Mg合金燃烧温度更高,燃烧速率也更快,燃烧持续时间更短。燃烧环境温度对微爆的发生有重要影响,因此对点火延迟时间和总时间影响较大,但对燃烧持续时间影响较小。对比相同粒径Al粉点火和燃烧性能,Al-Mg合金的燃烧持续时间降低为Al粉的20%~25%,但是点火延迟时间基本没有变化。该结果与电热丝点火实验[34]以及热分析实验[33]的现象存在明显区别,说明合金燃料的点火行为受到多方面参数的影响,包括升温速率、环境压力和温度、氧化剂的组成或燃烧组织形式等,因此在不同类型的点火或燃烧实验中可能表现出不同的燃烧反应特性。

图4 燃烧过程的3种典型微爆现象

Fig.4 Three typical microexplosion phenomena for the Al-Mg alloy particles were ignited

除元素组成和燃烧条件以外,合金燃料的相组成以及制备工艺也是燃烧性能的重要影响因素。使用机械合金化方法制备的合金,其各组元在相接触的位置上形成接近原子级均匀的复合物; 随着球磨时间的延长,各组元通过晶粒细化、固态扩散或固态反应的方式形成原子间结合的固溶体合金或中间合金[39]。相对于熔炼法获得的固溶体相,机械合金化可以诱导固溶度扩展,并形成偏离平衡相图的过饱和固溶体[40]; 同时由于多数铝基金属间化合物的生成焓为负值,过饱和固溶体会在较低温度下先发生合金化反应(形成金属间化合物),伴随着大量的热量释放,利于点火和燃烧的发生。

Hatem等[35]对比研究了Al-Mg机械化合金(MA,不含中间合金相)与Al-Mg金属间化合物(Mag,只含中间合金相)的点火和燃烧性能(见图5)。

图5 (a)Al-Mg熔炼-气雾化合金和机械化合金的EDS元素分析图像;(b)Al-Mg熔炼-气雾化合金和机械化合金的点火图像

Fig.5 (a)EDS Mapping images of magnalium and mechanically activated Al-Mg;(b)Ignition images of magnalium and mechanically activated Al-Mg

研究发现Al-Mg金属间化合物的点火延迟是Al-Mg机械化合金的近5倍,同时推进剂燃烧残渣的分析表明Al-Mg机械化合金燃烧残渣比Al-Mg金属间化合物燃烧残渣粒径更小,佐证了低温合金化反应对于Al-Mg合金点火和燃烧的促进作用; 对于仅有中间合金相的含Mg铝基合金燃料而言,即使无法通过低温合金化反应促进点火燃烧,Mg蒸汽产生的应力同样有助于氧化膜的破裂和氧化反应的进行,含Mg铝基合金燃料释能特性依然优于铝粉。在恒压燃烧实验中,Al-Mg合金中的亚稳相在点火燃烧过程中首先发生合金化反应,形成中间合金Al12M16并快速放热,同时合金相转变过程中产生的裂缝造成初始微粒破碎,增大燃烧面积,使Al-Mg合金在非常窄的预热区内升至点火温度,其悬浮颗粒的火焰前端比纯铝粉火焰边缘更锐利[36],该实验证实合金化反应的放热有利于点火的发生。

(3)Al-Zn合金

西北工业大学的Ao等[41]对包括Al-Zn合金(Zn质量分数为10%)在内的铝基合金燃料进行了燃烧性能研究。研究发现Al-Zn合金可以降低铝的氧化温度和点火性能,但是在Al-AP-RDX-HTPB推进剂中燃烧时未观测到微爆现象,且团聚现象比铝更严重。研究人员认为Al-Zn合金具有更低熔点的同时,并没有提高推进剂的燃速,延长了熔融的合金燃料在燃面上的停留时间,导致了熔融团聚程度的增大。北京理工大学的Jiao等[42]也研究了Al-Zn合金的点火和燃烧性能,其中Zn质量分数为20%,此时Al-Zn合金由α-Al相和η-Zn相组成,在不同激光功率密度下的点火延迟均比纯铝降低约50%,同时含Al-Zn合金的Al-AP-RDX-HTPB推进剂的燃烧中可观测到微爆现象(见图6)。

图6 HTPB推进剂中Al-Mg和Al-Zn合金的微爆现象

Fig.6 Microexplosion phenomenon of Al-Mg and Al-Zn alloys on the combustion surface of HTPB based solid propellants

将燃烧残渣收集分析后发现纯铝推进剂的凝聚相产物团聚尺寸高达300μm,而Al-Zn合金推进剂的凝聚相产物团聚程度明显减轻,SEM图像显示其粒径主要分布在100μm以下。在燃烧过程中,随着温度上升,Zn开始蒸发,燃料液滴内外Zn的浓度梯度使液滴表面附近形成扩散层。燃料液滴核心温度超过Zn的沸点时,诱发了均匀的颗粒内蒸汽成核,直到扩散层的表面张力与外部压力的总和不能再维持应力,燃料液滴破碎并发生微爆。因此,Zn含量的上升使液滴内外Zn的浓度梯度和应力增大,微爆更容易发生; 而燃烧环境压力的上升则使液滴破碎所需应力增大,微爆更难以发生。上述研究使用的推进剂配方组分相似(分别为13%HTPB/17%Al-Zn/60%AP/10%RDX[41]和14%HTPB/16%Al-Zn/60%AP/ 10%RDX[42])。材料本征性质(Zn浓度)变化和可能的实验工况变化,使燃料颗粒的微爆现象、团聚情况和推进剂凝相产物粒度出现了显著差异。

综上所述,低沸点金属在燃烧时可以通过微爆和分散沸腾现象降低燃料的熔融团聚程度,即在较低的温度下达到低沸点组分的过热极限,通过颗粒内蒸汽成核,利用蒸汽浓度梯度产生的应力突破氧化膜对氧传递的扩散阻碍,因此具有比铝粉更优异的点火和燃烧性能。目前作为燃料常用的低沸点金属多为反应活性高的碱金属或碱土金属,在空气中容易氧化导致活性降低; 其中碱金属是还原性最高的金属种类,形成合金后与推进剂中的氧化组分可能存在相容性问题,需要通过包覆等手段进行稳定化处理以满足应用需求。此外,低密度碱金属或碱土金属的添加还会造成合金燃料密度的降低,在对密度有要求的推进剂中需结合高密度金属燃料使用。

在低熔点金属中,Si的燃烧热为32.4kJ/g,是一种高热值固体燃料,Ti和Zr虽然质量热值较低,但是由于具有较高的密度,其体积燃烧热均与Al相当,结合其良好的点火性能,在对密度比冲有所要求的推进剂中具有一定应用前景[43]。此外,在高燃温固体推进剂中,凝聚相的Al2O3更容易汽化,加剧发动机燃烧室的不稳定燃烧,需要沸点更高的凝聚相产物来抑制不稳定燃烧,因此,部分铝-低熔点金属合金还是一种具有应用潜力的燃烧稳定剂。

(1)Al-Si合金

采用雾化法制得的Al-Si合金燃料由α-Al和β-Si相组成。Si质量分数为12%时,合金燃料经盐酸腐蚀后表面呈现出枝状Si和少量片状Si组成的多孔结构(见图7); Si的质量分数提升至20%时,两种相的空间分布具有核壳结构特征:粉体的壳层由片状初晶Si和无定型Al2O3组成,核心部分由低熔点共晶形成的网状骨架以及填充在内的α-Al组成。由于核心部分共晶的熔点低于铝,熔化膨胀后与氧化剂接触,使得Al-Si热氧化反应的第一阶段比Al提前; 随着温度升高,壳层中Si不断被液态Al-Si溶解并形成氧化通道,α-Al的氧化反应逐层深入产生晶须Al2O3结构,并发生剧烈熔胀喷发,使Al-Si合金氧化反应第二阶段增重大幅提高; 而β-Si活性相对α-Al更低,直到800℃才会发生氧化反应,因此Al-20Si(Si质量分数为20%)最终反应程度相对Al-12Si(Si质量分数为12%)较低。Al-Si合金的燃烧热遵循与热氧化同样的规律,Al-12Si的实测热值为29.285kJ/g,高于Al和Al-20Si的实测热值[44]。电爆炸法获得的合金相较于雾化法制得的Al-Si合金具有类似的核壳结构,其核心部分的低熔点共晶呈现从球心向外辐射的纳米棒形态,其热氧化反应特征同样类似于雾化法Al-Si合金,相对于同粒度铝粉热氧化反应温度提前,且氧化反应增重大幅提高[45]。

(2)Al-Zr合金和Al-Ti合金

Ti和Zr的沸点远高于推进剂燃烧温度,燃烧时无法通过金属蒸汽的应力突破氧化膜的阻碍,但是它们的氧化物可以溶解在金属单质中,不会形成阻碍氧扩散的氧化膜。将高密度的Ti和Zr添加到Al或铝基合金燃料中,可以形成兼具优良能量性能和燃烧性能的合金燃料。例如Al-Mg二元合金的密度随着Mg含量提高而降低,密度提升与点火性能提升的需求之间存在矛盾。李林福等[46]将高密度的Zr引入Al-Mg二元合金,使用气雾化法获得了Zr质量分数为2%的Al-Mg-Zr三元合金燃料,该方法所制合金主要由Al和金属间化合物Al3Mg2、Al12Mg17和Al3Zr组成,其反应机理与机械合金化得到的二元合金有所不同,在氧化过程中不易发生促进点火的合金化反应,然而实验发现,随着Mg含量的提高,Al-Mg-Zr合金由多步氧化放热变为单步集中放热。针对该现象,研究人员提出了类似于铝粉熔散反应机理的Al-Mg-Zr合金的氧化机制:随着温度的升高,颗粒内部低熔点的Al3Mg2、Al12Mg17形成Al-Mg熔体和Mg蒸汽,当Mg含量及其产生的应力足够高时导致氧化层的破裂,在内外压力差的影响下,Al-Mg熔体逸散成小液滴后与氧发生反应并剧烈放热,导致Al3Zr相大颗粒爆裂成超细颗粒(见图8)。Al-Mg熔体小液滴和Al3Zr超细颗粒的剧烈氧化反应导致了Al-Mg-Zr合金单步集中放热现象的出现。

图8 Al-Mg-Zr合金的氧化和颗粒细化机制示意图

Fig.8 Schematic diagram of mechanism of oxidation and cracking of Al-Mg-Zr alloy powdersDreizin

团队亦对Al-Ti机械合金燃料进行过较为系统的研究。Shoshin等[47]制备了不同Ti含量的Al-Ti合金,当Ti质量分数为10%时,合金燃料的点火温度从纯铝的2150K降低到了1326K,随着Ti质量分数的增大,点火温度和颗粒燃烧时间进一步降低。此外,在对Al-Ti合金的DSC热分析实验中观察到了Al3Ti亚稳合金相之间转变的放热峰,说明Al-Ti合金在点火燃烧过程中也存在合金化反应放热的现象,其中L12相Al3Ti生成时的放热有助于点火的发生[48]。对Al-Ti、Al-Zr合金在层流火焰燃烧的研究中,观察到了比铝更快的火焰传播速度[49]。在此基础上,Badiola[50]利用冷冻球磨降低Al-Ti合金的延展性,得到了平均粒度相对更低的Al-Ti固溶体合金,燃料粉尘的密闭爆发实验结果说明冷冻球磨所得的Al-Ti固溶体合金点火延迟明显低于非冷冻球磨得到的Al-Ti合金。

合金化反应促进燃烧的现象在铝-过渡金属(Transition Metal)的合金燃料(Al-TM)中广泛存在。Alexander等[51]使用电爆炸法制备了Al-Cu合金和Al-Ni二元合金燃料,Al-Cu合金热氧化温度(升温速率β=2~7℃/min)提前且反应完全率提高,两种合金的实测燃烧热均提高,点火温度降低(升温速率β=10~30℃/min),研究人员认为这是固溶体系的合金化反应放热提前造成的。

(3)Al-稀土合金

除上述p区元素和d区金属外,f区的稀土元素由于原子核对外层电子的束缚较弱,也是一类反应活性很高的金属元素,大多数稀土在200℃以下的空气中即可自燃。高化学活性、低点火温度和高燃烧热使稀土元素作为铝基合金燃料的添加剂具有明显优势,同时Eu和Ce等高活性稀土也属于低熔点金属。Fu[52]在Eu质量分数1%~5%的Al-Eu合金中未检测到Eu氧化物的衍射峰,说明Al-Eu合金在室温下的稳定性。当温度提升至1065℃时,铝粉和Al-Eu合金都出现了一个氧化放热峰,Al-Eu合金的放热峰峰形更为尖锐,氧化反应后的增重达到61.1%,明显高于纯铝粉27.9%的增重,说明Al-Eu合金的氧化过程更剧烈、反应更完全。研究人员认为Al-Eu合金优良的氧化反应特性取决于其Al4Eu相的氧化通道作用:从相组成上看,Al-Eu合金的由Al和Al4Eu组成; 从相组成的空间分布看,狭长的纳米尺寸Al4Eu相将粉末内部的Al隔离成亚微米尺寸的晶粒。在氧化过程中,Al4Eu相首先被完全氧化为Eu2O3和Al2O3,这种混合氧化物不如纯Al2O3一样致密,在后续Al单质的氧化过程中提供了氧扩散的通道[见图9(a)和(b)]。从Al-Eu合金粉末氧化后的颗粒截面中可以发现,由于Al4Eu氧化通道的存在,粉末内部从晶界处已经开始氧化,同时粉末有沿着晶面爆裂的趋势,提高了颗粒与氧接触比表面积的同时缩小了燃烧半径,使得Al-Eu合金氧化放热速率和反应完全程度较单质Al粉更高[见图9(c)]。

上述研究表明,Al-MLM合金具有多种提高燃烧效率的途径:MLM是过渡元素且与铝形成过饱和固溶体时,两种元素之间的紧密复合使其相互扩散的能垒大幅降低,可以在较低的温度下发生合金化,电子杂化和化学势的差异使Al-过渡金属(TM)的金属间化合物具有负的生成焓,因此燃烧过程中发生的Al-TM合金化过程是放热反应,额外的热量释放可以促进合金燃料的点火和燃烧; MLM与铝形成金属间化合物时,可能通过熔散反应机制使燃料发生崩裂和细化,这种机制发生在熔融铝在限制氧化壳的膨胀所产生的高压下。当氧化壳破裂时,内部和外部压力之间的不平衡产生了一个高于铝的空化压力的卸载波,这导致铝液滴被分散并最终喷出。与纯铝相比,Al-Ni等熔融态合金具有更高的体积膨胀率和较低的空化压力,更有可能被卸荷波散射出去。合金化降低了熔散反应机制的启动条件,促进了熔体分散现象,使合金燃料的能量释放更为集中; MLM是高活性的稀土元素时,其氧化物可作为氧化通道,提升传质的同时增大与氧接触的面积,使燃烧化学反应更为剧烈和完全。

(1)Al-B合金

硼(B)是目前富燃料推进剂中最常用的燃料,作为同时拥有最高质量热值和最高体积热值的单质,将B添加至铝基燃料中,有望提高合金燃料的燃烧热。然而,在硼燃烧时,熔点低、沸点高的氧化硼以液态的形式包覆在燃料外层,这层氧化膜难以破裂,阻碍燃烧的继续进行[53]。因此,含硼铝基合金燃料应用的关键在于如何提高含B燃料的燃烧效率,充分发挥其理论热值高的优势。为获得高热值合金燃料,Wang等[54]将B元素引入Al-Eu体系中形成Al-B-Eu三元合金粉末,Al-B-Eu三元合金氧化过程增重53.66%,实测质量燃烧热为33.324kJ/g。研究表明,在Al-B-Eu三元合金燃烧过程中,被氧化的B元素以Al8B2O15和EuB2O4的形式存在,避免了液态B2O3对氧化反应的阻断作用,使得Al-B-Eu三元合金释能更完全。

(2)Al-W合金

由于钨(W)的熔点高达3410℃,高于铝的沸点,Al-W属于难互溶体系,无法用熔炼法制备。科研人员使用铝热还原-气雾化制备了不同质量分数的Al-W合金,其中W质量分数20%的Al-W合金粉末具有最高的体积热值[55],Al-W(W质量分数30%)合金粉末内部含有Al-W非晶合金相和亚稳相Al-W金属间化合物,这些亚稳合金相在合金粉末退火过程中晶化或转变形成Al12W并放热。随着温度的进一步升高,Al12W在600~750℃和750~900℃两段温度范围内先后吸热转变为另外两种稳定相Al4W和Al5W,直至900℃开始剧烈氧化,生成Al2O3和Al2(WO4)3并大量放热,温度升高至1100~1300℃时,Al2(WO4)3吸热分解为WO3并完全挥发,固体产物中最终只剩下Al2O3[56]。

铝基燃料高热值、高密度的特点,使其成为固体推进剂重要的能量组分。从能量的角度来看,合金燃料的燃烧效率提升使铝的反应更完全,避免不完全燃烧造成的释能减少和能量损失; 同时燃烧效率提升有助于减小凝聚相产物的尺寸[2],削弱两相流损失对比冲的负面影响。此外,推进剂能量的实际效用还与密度有关,高密度合金燃料的添加可以提升推进剂的密度,在有限的发动机体积内装填更高质量推进剂,实现火箭武器射程的提升或有效载荷的增大。

另一方面,从固体推进剂的燃烧性能角度而言,合金燃料与铝粉在燃烧过程中具有不同的吸放热特性,各种金属元素还会不同程度地影响气相或凝聚相中的燃烧化学反应动力学,这意味着合金燃料可以调控固体推进剂的燃烧性能。本节从能量提升和燃速调控两方面具体介绍合金燃料在固体推进剂中的应用研究概况。

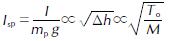

铝基合金燃料根据其组成、结构以及自身物化特性,通过不同方式在推进剂中能量性能提升方面表现出了较好的应用效果。根据理论比冲与推进剂各项参数之间的关系[29]:

提升固体推进剂理论比冲的途径基于热力学控制:提高燃烧温度,降低燃气平均相对分子质量。在理论比冲的基础上,通过提升能量释放效率,降低能量损耗等动力学控制手段可以获得更高的实测比冲。此外,密度比冲的提升则有利于在有限容积的发动机内产生更大推力。

对于大部分推进剂配方,铝达到了燃烧热值、耗氧量和密度的良好平衡。因此,以15Al-70AP-15HTPB推进剂为例,除铝以外大部分金属加到推进剂中都会使理论比冲下降(见图 10)。而Al-Li合金的加入可以提高固体推进剂的理论比冲(见图 11)。

图 10 二元金属对固体推进剂理论比冲的影响

Fig.10 Effect of bi-metallic fuels on the theoretical specific impulse of 15Al-70AP-15HTPB propellants

图 11 含Al和含Al-Li合金固体推进剂的理论比冲

Fig.11 Ideal specific impulse for fuel additive/AP/HTPB propellants, fuel additive Al and Al-Li alloy

根据推进剂能量计算的自由能最低原则,在含Al固体推进剂中,通过氧化剂种类的选择、燃料元素的分配和氧燃比的调整进行能量优化后,H元素倾向于生成H2以获得更低的燃气平均相对分子质量,O元素倾向于生成Al2O3以获得更高的能量释放和燃气温度。Al-Li合金加入后,在Li元素的作用下,相同分子量的HCl转变为H2和LiCl,燃气平均相对分子质量降低,导致了理论比冲的上升[29]。

然而,Al-Li合金的活性很高,化学相容性、工艺安全性和储存稳定性是其在推进剂中应用亟需解决的问题。针对Al-Li合金活性过高导致氧化失活的问题,研究人员对Al-Li合金活性保护方法进行了探索,使用液相化学沉积法在Al-Li合金外包覆了一层质量分数约为7%的Fe单质纳米颗粒,经过60天的室温储存后,Fe@Al3Li仅损失了1.2%的热值,而未包覆的Al3Li的质量燃烧热下降了4.3%[57]; 采用原位聚合法对Al-Li合金包覆了苯乙烯(St),当苯乙烯添加量m(St):m(Al-Li)=1:1时具有相对最佳的活性保护效果,考察Al-Li合金燃料14天老化后的热氧化性能,热增重衰减由包覆前的25.5%降低至包覆后的6.5%[58]。上述研究说明了采用金属单质或聚合物包覆的方法在改善高活性合金燃料的活性保护方面具有一定效果,但同时也导致了活性金属含量降低问题的出现。

Al-Li合金可以提高推进剂理论比冲的同时,对于燃烧效率提升以及推进剂二相流损失降低也具有正面效果:微爆的发生使凝聚相产物中的Al2O3粒径减小,而Li的燃烧产物LiCl在燃烧火焰温度下以气相形式存在,取代了纯Al推进剂中凝聚相的铝化合物,对于二相流损失的降低也具有促进效果[29]。

Huang等[59]分别将Al-Mg中间合金(AM)和Al-Mg机械化合金(b-AM)作为燃料以相同的元素比例取代Al-AP-HTPB中的铝、镁单质金属燃料,制备得到金属/水反应推进剂,研究了不同燃料在推进剂中的燃烧效率。其中铝在b-AM和AM在高温水蒸汽中的反应效率分别为90.6%和83.8%,而铝粉的反应效率仅为25.1%,上述两种Al-Mg合金燃料具有远高于铝粉的反应完全性。在推进剂中经过一次燃烧和二次燃烧后,根据二次燃烧固产物中的活性铝含量计算燃烧效率,研究发现AM和b-AM中的镁均完全燃烧,合金中的铝燃烧效率分别93.6%和90.2%,优于铝粉的燃烧效率(67.3%)和铝粉/镁粉混合物的燃烧效率(86.3%)。对固相燃烧产物的分析发现,AM和b-AM中铝的反应产物主要为Al2MgO4,而铝粉的反应产物为Al2O3,疏松多孔的Al2MgO4难以阻碍氧化反应和燃烧的深入,因此Al-Mg合金在推进剂中具有比铝粉更高的燃烧效率。除上述Al-Mg中间合金和机械化固溶体合金外,研究发现机械合金化制备得到的Al-Mg中间合金(ba-AM)具有更高的燃烧效率,含有ba-AM的推进剂具有比含AM的推进剂更高的爆热和二次燃烧效率[60]。研究人员认为机械合金化提高燃烧效率的原因是球磨过程破坏了氧化膜的完整性,同时机械力导致的形变使燃料获得了更大的比表面积。

Hatem等[35]发现Al/Zr和Al/Mg等多种合金燃料可以通过燃烧过程的特殊现象减小燃烧凝聚相产物尺寸,合金燃料的燃烧现象与其相组成和元素组成密切相关。对于不同相组成的Al/Mg合金燃料而言,推进剂燃烧图像上可以观察到Al/Mg中间合金的微爆现象和Al/Mg机械化合金的颗粒破碎现象,使得含上述两种Al/Mg合金的HTPB-AP推进剂燃烧后,凝聚相产物粒径相对于以铝粉为燃料更小。此外,合金中镁的含量、燃料粒度分布和燃烧室压力均会影响燃烧凝聚相产物的粒径分布。除Al/Mg外,研究人员还发现Al/Zr机械化合金可以使燃烧凝聚相产物中小粒径的产物比例增大,对于Al/Zr而言,即使在凝聚相产物粒径分布相同的情况下,ZrO2由于具有较小的比热容,其造成的二相流损失相对于Al2O3低了2.7倍[61]。

上述合金燃料的燃烧特性使其具有更高燃烧效率和更低的二相流损失,可以通过自身的高效燃烧以提升固体推进剂比冲效率,对于实测比冲的提高具有积极作用。

Zr、Ti、Ta和Mn等[62]金属的高密度使其具有与铝相近甚至高于铝的体积热值,这些高密度金属燃料的添加可以提高推进剂的密度。根据Tsiolkovskii公式,推进剂的有效载荷与推进剂的比冲、推进剂的密度均为正相关。研究发现[63],当推进剂体积和发动机空重的比值为0.27L/kg时,使用Zr替代铝粉的推进剂配方虽然比冲有所降低,但是可以大幅提高多种复合固体推进剂的密度,等效比冲可以提高30.4s,有效载荷质量也随之提高。把高密度的金属与铝结合可以得到高密度铝基合金,这种高密度铝基合金燃料也可有效提高推进剂的密度。Mark等[64]的研究发现,使用球磨法获得的Al/Zr(质量分数25%/75%)密度高达4.82g/cm3,比铝粉的密度提高了78.5%; 将Al/Zr和铝粉分别制得推进剂,所得Al-AP-HTPB/IDP和Al/Zr-AP-HTPB/IDP推进剂密度分别为1.90和2.84g/cm3,Al/Zr的添加使推进剂密度提升49.4%。对比Al-AP-HTPB/IDP和Al/Zr-AP-HTPB/IDP复合推进剂的能量性能,Al/Zr使推进剂的质量比冲由263s降低为248s,而体积比冲由499.7s提升至706.0s。Al/Zr合金燃料在有效提高推进剂密度的同时,还可提升推进剂的制备工艺安全性,这是由于Zr粉具有自燃的特性,在推进剂中直接使用存在安全风险,而延性良好的Al在球磨过程中覆盖在Zr的表面,形成的合金燃料对其中的Zr具有稳定化作用,降低其对静电的敏感性,相较于直接使用Al/Zr物理混合燃料更为安全。

在利用合金燃料提高能量的同时,需要综合考虑合金燃料对固体推进剂燃速的影响。或利用合金燃料的催化作用进一步提高推进剂的燃速,或使用不影响燃速或降低燃速的合金燃料将推进剂的燃速控制在一定的范围,以满足不同的使用需求。因此,探索合金燃料对固体推进剂的燃速调节作用具有重要意义。

通过物理过程调控推进剂的燃速方面,合金燃料对推进剂燃速的调控主要与燃烧过程的热量变化有关,例如通过较低的点火延迟时间和能量释放,改变推进剂的燃烧波温度分布,提高推进剂的燃面温度,使凝聚相的热分解速率加快,从而提高燃面退移速率; 同时,金属相对于有机黏合剂更高的热导率使热量加速向凝聚相传导,从而加快凝聚相的热分解速率。通过对燃烧化学反应的催化作用调控推进剂的燃速方面,由于铝的还原性和火焰区环境的氧化性,铝基燃料中的合金元素会存在单质和氧化物的不同状态[16]。因此,除中间合金相外,燃烧过程中可能出现的金属单质及其氧化物同样可以作用于推进剂组分的热分解过程,进而影响推进剂的燃烧性能[65]。

双基系推进剂主要的黏合剂骨架/基体是硝化纤维素,复合推进剂的黏合剂骨架类型有聚丁二烯、聚氨酯和聚醚等,不同组成的合金燃料对凝聚相内不同组成的黏合剂热分解行为具有差异; 此外,对于不同配方组成的推进剂而言,其气相火焰区的化学组成和空间分布有明显区别,不同组成的合金燃料对气相化学反应的催化作用具有差异。因此,合金燃料对于不同的黏合剂体系具有不同的燃速调控效果。基于不同的固体推进剂黏合剂种类,分别整理了铝基合金燃料的燃速调节作用,讨论了黏合剂种类、氧化剂组成和合金燃料对固体推进剂燃速的影响。

合金燃料对改性双基推进剂燃速调节的研究方面,李军强等[66]研究了质量分数5%铝粉、硼粉或Al-Mg合金粉的添加对NC/TMETM/FOX-7低感度改性双基推进剂燃烧性能的影响(见表2)。结果表明铝粉和Al-Mg合金燃料的添加均提高了NC/TMETM/FOX-7改性双基推进剂的燃速,其中Al-Mg合金燃料对燃速提升的幅度最大,6MPa下的燃速由15.21mm/s提升至17.11mm/s,增幅为12.5%; 16MPa下的燃速由21.58mm/s提升至27.74mm/s,增幅为28.5%。相对而言,推进剂的高压燃速比低压燃速提升幅度更高,因此Al-Mg合金对NC/TMETM/FOX-7改性双基推进剂的燃速压强指数影响较大,在12~14MPa下的压强指数从0.21提高至0.48。

除双基系推进剂外,复合推进剂中添加Al-Mg合金也可以有效调控其燃烧性能。Hatem等[67]对比研究了相同金属比例的Al-Mg机械化合金和Al-Mg金属间化合物(添加量均为15%)替代纯Al后对HTPB-AP推进剂燃速的影响,发现两种不同结构的合金均可提高推进剂燃速,其中点火温度更低的机械化合金对燃速的提升幅度更大。Francesco[68]的研究发现,对于HTPB-ADN推进剂而言,Al-Mg合金的燃速调控效果与改性双基推进剂及HTPB-AP推进剂正好相反,含质量分数16%Al-Mg机械化合金使HTPB-ADN推进剂在4~13MPa压力范围内的燃速均低于含纯Al粉的配方。对于高燃速GAP-ADN推进剂而言,Al-Mg合金的燃速调控效果再次改变,含质量分数17%Al-Mg机械化合金使推进剂的燃速相对于含Al配方有明显提升。结合Al-Mg合金燃料对不同配方体系推进剂的燃速影响规律,上述研究工作说明了当推进剂配方中的氧化剂、黏合剂成分发生变化时,合金燃料的燃速调控作用也随之改变,推进剂的燃速是配方各组分相互作用的结果。

研究人员认为金属燃料粒度的降低使推进剂的燃烧由扩散控制转变为了动力学控制,从而导致燃速和压强指数的上升。Terry[69]考察了Al-Si合金燃料及其粒度对HTPB推进剂燃速的影响规律,结果表明Al-Si合金完全取代铝粉后,推进剂的燃速和压强指数均下降,其中细粒度的Al-Si合金具有相对更高的燃速和压强指数。Byoung等[70]的研究同样证实了Al-Zr对HTPB推进剂燃速的提升作用,以及Zr粒度的降低可以进一步提升推进剂燃速。

此外,研究人员发现压力的提高会降低液态Al液滴中Li蒸汽气泡的增长速度,从而抑制Al-Li合金微爆现象及其细化燃料的作用。燃面附近淬灭的凝聚相产物分析表明了压力提升会降低燃面附近Al-Li合金完全燃烧程度和热反馈作用,这可能是Al-Li合金在HTPB推进剂中产生燃速平台的原因[71]。

由于固体冲压发动机对于流量调节的需求,与常规固体推进剂有所不同的是,富燃料推进剂对燃速压强指数有更高的要求。Al-Mg合金在多种推进剂中表现出了对压强指数的提升效果,其加入可使富燃料推进剂满足高燃速压强指数的需求。毛根旺等[72]研究了Al-Mg合金对含硼富燃料推进剂燃烧性能的影响,结果表明推进剂的燃速和压强指数随Al-Mg合金燃料添加量增多而提高,Al-Mg合金的质量分数在3%~10%范围内时,Al-Mg合金每取代1%HTPB,推进剂的燃速平均上升31%,燃速压强指数平均提高0.02,研究人员把燃速提高的原因归结为金属较高的导热率对热反馈的提升作用。Liu等[73]考察了Al-Li合金对B/PTFE富燃料推进剂燃速的影响规律,研究发现推进剂的燃速随着Al-Li合金取代B的含量增加而提升,研究人员认为Al-Li燃烧放热以及燃烧产物中的LiF对于B的燃烧具有促进作用,从而提高了推进剂的燃速。

O. G. Glotov等[74-75]研究了Al-B合金燃料对不同推进剂的燃速影响规律。在Al-AP-HTPB推进剂中,Al-B合金燃料的粒径是影响燃速的主要因素,当合金燃料的粒径与Al接近时,Al-B合金取代Al粉使推进剂的燃速在0.1MPa和4.2MPa下分别提升28.5%和94.2%; 而其他机械合金化参数获得的Al-B合金燃料粒径均为Al粉的3倍以上,在0.1MPa和4.2MPa下对推进剂燃速的提升效果均小于36.2%[74]。对于Al-AP-HMX -HTPB四组元推进剂,Al-B合金燃料取代Al粉使推进剂在2.0~8.0MPa范围内燃速上升、压强指数下降[74]。在聚甲基乙烯四唑为黏合剂的含B推进剂中对比研究了AlB2金属间化合物和Al-B机械化合金对燃速的影响规律,结果表明在约1.2MPa和2.5MPa压力下使用Al-B机械化合金取代B粉可以提升该推进剂的燃速,而AlB2金属间化合物则会降低燃速[75]。在固体推进剂配方中用Al-B合金代替Al时,由于B的燃烧耗氧量远大于Al,B与每单位氧化剂反应的放热量低于Al,需要增加高氧平衡(通常生成焓较低)氧化剂的含量以维持燃氧比,导致比冲的不升反降。从提升理论比冲以及燃烧效率的角度看,与其他合金燃料相比,Al-B合金更适用于富燃料推进剂。因此,目前Al-B合金在非富燃料推进剂的应用研究主要集中在对推进剂燃速的影响规律方面。

铝基燃料中引入合金元素可以形成不同组成和相结构的合金燃料,理化性质的差异使合金燃料具有与单质燃料不同的本征特性和燃烧反应机制。耗氧量、水/氧稳定性、组分的相容性等理化性质以及点火和燃烧性能是评价合金燃料在推进剂中应用潜力的重要指标。特定元素和相组成的铝基合金燃料可通过微爆、合金化反应放热、形成氧化通道等机制增加自身燃烧性能; 部分高活性的金属元素如锂、稀土对水和氧敏感,在实际应用中会有工艺安全性问题和长期储存过程中的反应活性降低问题。铝基合金燃料应用在固体推进剂中,可以通过提升理论比冲、提升能量释放效率、降低能量损耗、增加密度等方式提高能量性能,还能调控不同配方类型的推进剂的燃速和燃速压强指数。在上述结论和分析的基础上,合金燃料的重点研究方向为:

(1)研究铝基合金燃料的制备方法与参数对组成和结构的影响规律,输入能量的种类及制备过程经历的相图路径等因素决定了铝基合金燃料的相组成和空间分布,完整“制备工艺-结构-性能”关系的获得是应用和设计技术的保障。

(2)针对工艺安全性和长期储存活性降低问题,对高反应活性合金燃料进行包覆等改性处理以提高其水/氧稳定性以及与推进剂组分之间的相容性。

(3)解析铝基合金燃料对固体推进剂的燃速调节机制。目前相关研究主要从宏观物理过程对金属或合金燃料的燃速调节作用进行分析,需要深入研究金属元素类型、氧化态以及合金相在燃速调控中的微观化学机制。

(4)完善铝基合金燃料的燃烧机理研究方法。研究人员已通过多种热分析、激光点火、平面燃烧器和推进剂燃烧等方式获得了合金燃料在相应条件下的点火燃烧机理,但是各种方法之间从传质(燃烧环境组成和燃烧组织方式)、传热(点火能量提供方式、燃烧环境温度、单颗粒/颗粒堆的热环境区别)、传动(静态或动态燃烧、燃烧流场)方面存在较大差异,其反应机理和释能方式普适性受限。需要考察热氧化反应与燃烧反应的机理差异、激光/电热等不同点火方式与燃料的相互作用差异、单颗粒/颗粒堆/燃气流场/固体推进剂燃烧等燃烧组织形式中铝基合金燃料的反应释能机理差异。