基金项目:国家自然科学基金(No.11772060)

作者简介:高家乐(1997-),男,硕士研究生。E-mail:3120200189@bit.edu.cn

通信作者:周霖(1962-),男,教授,博导。E-mail:zhoulin@bit.edu.cn

(1.北京理工大学 机电学院,北京 100081; 2.安徽理工大学 化学工程学院,安徽 淮南232001; 3.重庆红宇精密工业集团有限公司,重庆 402760)

(1.School of Mechatronical Engineering, Beijing Institute of Technology, Beijing 100081, China; 2.School of Chemical Engineering, Anhui University of Science and Technology, Huainan Anhui 232001, China;3.Chongqing Hongyu Precision Industry Group Co., Ltd., Chongqing 402760, China)

anti-overload performance; explosive charge; visco-SCRAM model; DNAN-based melt cast explosive; numerical simulation; RBHL-1; explosive safety

DOI: 10.14077/j.issn.1007-7812.202203031

炸药在运输和使用过程中承受着各种各样的过载,包括跌落、撞击、发射、侵彻等,在这些状态下,炸药处于复杂的应力环境中,存在意外点火的风险,严重影响炸药性能的发挥以及人员安全,因此研究炸药在过载条件下的点火机制尤为重要。

钻地武器以地下工事为目标,其在侵彻混凝土过程中应力小于1GPa,脉宽在毫秒量级[1],这种情况下炸药即使所受压力低于冲击起爆阈值,也有可能发生延迟爆轰。战斗部侵彻混凝土目标靶板过程中,战斗部炸药装药将发生较大的宏观变形。这一变形产生的原因包括弹丸在靶板滞止作用下产生的惯性冲击载荷作用和来自弹丸壳体的挤压作用。这是一种复杂的压缩-剪切复合作用。陈朗等[2]在连续低冲击加载炸药的双隔板实验中,观察到了JO-9159炸药延迟起爆(XDT)现象; 柯加山等[3]介绍了研究XDT现象的试验和数值模拟方法; 但均未建立以细观损伤为基础的描述炸药宏观力学行为的模型。

目前研究机械刺激对炸药抗过载性能的影响主要通过撞击感度、摩擦感度、大型外场试验和实验室规模的加载装置等手段。撞击感度和摩擦感度的试验样品为炸药颗粒/粉末,颗粒/粉末状的样品与炸药装药在力学响应上有很大差别; 大型外场试验受成本限制,严重影响着研究进度。北京理工大学黄正平教授研制了小型后座模拟器[4],西安近代化学研究所研制了大落锤试验装置[5],两者的试验件结构类似,存在药柱不能径向变形的问题。中国工程物理研究院研制的落锤仪[6],该试验件结构在被试药柱周向增加了聚四氟乙烯缓冲垫,但聚四氟乙烯直接与药柱接触,在试验打击过程产生的高温环境下聚四氟乙烯可能会诱导药柱发生反应,会影响试验结果。鉴于以上试验装置的局限性,基于对战斗部侵彻混凝土靶板炸药装药响应特点的研究,北京理工大学周霖教授团队[7]发明了一种炸药抗过载性能评估装置,炸药装药在侵彻过程中由于战斗部壳体发生弹塑性变形迫使与壳体接触的炸药发生较大剪切-压缩变形,该过程炸药受到压缩-剪切-摩擦作用,此装置基本可以模拟炸药装药在侵彻等过程中所承受的加载环境。

炸药抗过载性能评估装置可以得到炸药装药的响应,但炸药点火机制很难通过试验得到。目前炸药的点火机制主要包括孔洞塌缩和剪切摩擦等,前者是炸药孔洞塌缩过程中黏塑性功转化为热量导致的热点,后者为剪切力大于裂纹面静摩擦力后两侧裂纹相对滑动产生摩擦热导致热点生成。研究炸药的点火机制需要建立相应的模型。准确描述炸药在低压下的力学行为是预测延迟爆轰现象的前提。对炸药而言,采用简单的黏弹性模型就可以很好地描述炸药在不同应变率下的应力—应变曲线[8]。但是,当炸药开始发生损伤、接近失效时,简单的黏弹性模型已经不再适用,此时需要向黏弹性模型中加入损伤变量。基于缺陷成核增长的概念,Seaman[9]提出一种用于描述材料在射弹撞击、爆炸等加载条件下材料动态断裂过程的模型。该模型不仅能够计算韧性断裂问题,还能对脆性断裂问题进行计算。在对两种问题进行计算时,分别称为DFRACT(Ductile Fracture)和 BFRACT(Brittle Fracture)模型。炸药的失效应变较小,在动态加载条件下往往发生脆性断裂,可以采用BFRACT模型描述,不过BFRACT模型只允许单一的裂纹取向[10]。Dienes[11]计算了不同的热点机理对热点处释放出热量的贡献,结果表明剪切摩擦是热点形成的主要原因。据此,Dienes[12]提出SCRAM(Statistical Crack Mechanics)模型,该模型可以描述炸药的熔化、点火、慢速反应和快速反应。试验结果表明[13]SCRAM模型能够较好地描述炸药的动态损伤力学响应,并能够用于模拟XDT现象。但SCRAM模型存在参数过多很难应用的问题,因此Addessio和Johnson[14]对模型中裂纹进行了各向同性处理并简化了裂纹分布函数。在此基础上,Bennett等[15]将Maxwell黏弹性模型和简化后的SCRAM模型串联起来,建立了Visco-SCRAM模型。该模型已经成功应用于炸药在剪切[16]、侵彻[17]、撞击[18]等作用下的点火过程。

综上,Visco-SCRAM模型假定剪切摩擦是炸药的点火机制,但炸药装药在抗过载性能评估试验中的点火机制是否同样是剪切摩擦,这是本研究的主要内容。本研究基于所发明的抗过载性能评估装置的主体结构,建立了装置的仿真模型,采用Visco-SCRAM模型描述炸药的力学及热学行为,将Visco-SCRAM模型以二次开发的方式嵌入LS-DYNA,通过LS-DYNA对DNAN基熔注炸药(RBHL-1)在过载条件下的响应过程进行计算,并在此装置上进行试验验证,以揭示炸药装药在过载条件下的点火机制,为建立炸药抗过载性能测试与表征方法提供科学依据。

炸药抗过载性能评估装置主体部分结构示意图见图1[7]。主要技术参数如下:装置最大高度1.6m,装置总质量638kg,重锤质量46kg,最大自由程250mm,最大打击速度15m/s,过载(2~3)×104g,最大试样直径Φ30mm,可提供最大应力1.6GPa,脉宽2ms左右。

北京理工大学黄正平教授研制的小型后座模拟器[4]及西安近代化学研究所研制的大落锤试验装置[5]的试验件结构示意图见图2左图,该试验件结构在被试药柱上下端面增加了聚乙烯缓冲垫避免了边角摩擦,然而药柱周向与刚性模套直接接触,试验时炸药与模套内部会发生摩擦作用,同时,在刚性周向约束下炸药只有轴向应变,无法模拟侵彻加载。图2右图试验件结构药柱上下端面及周向均有聚乙烯材料的保护,隔绝了炸药直接与金属材料接触,避免了炸药与金属材料的摩擦,同时避免了被试药柱挤入模套与冲头之间的间隙中,导致意外点火,影响试验结果的真实性; 聚乙烯缓冲层在打击作用下近似为流体状态,将会从冲头与模套之间的间隙中挤出,产生较大变形,这种情况炸药能够产生轴向和径向变形。由于在整个变形过程中炸药药柱一直处于聚乙烯环的约束下,因此装药承受了较大的压缩剪切载荷。该试验件结构可以模拟战斗部装药在侵彻靶板过程中受到惯性冲击载荷而发生剪切压缩变形及变形过程炸药颗粒之间的摩擦作用。

试验时将气缸-重锤打击系统、试件承载系统、支撑系统、气路及控制系统和测试系统连接好,通过压缩空气瓶向连接有耐压管的气缸-重锤打击系统充入压缩空气,重锤与气缸通过铝合金剪切销钉连接,通过剪切销钉剪切面直径大小和自由程来控制重锤的打击速度,对应速度见表1。当气缸内的压力超过剪切销的抗剪强度时重锤被释放,气缸内壁给重锤的运动提供了轨道,重锤沿着气室内壁向下运动,以一定的速度打击上冲头。上冲头位于一个模套内,上冲头在重锤的打击作用下沿约束套筒内壁向下运动。上冲头非打击端放置有被测炸药样品,通过上冲头,将重锤的打击力传递至炸药样品,被试炸药样品在打击压缩作用下产生响应,并将受到的载荷传递至被试炸药样品底部的压力传感器。信号通过放大器,传递至数字示波器,进行采集、记录。

重锤以不同的打击速度加载时,炸药有一定的概率点火,借鉴落锤试验50%爆炸特性落高的概念,此处取炸药50%概率发生点火的加载速度为阈值速度,由于抗过载性能评估装置速度的调节不是连续的,所以一般得到的是阈值速度区间。对DNAN基熔注炸药(RBHL-1)试验时,从6.66m/s的打击速度开始试验,每个速度进行10发试验,若点火概率低于50%,继续增加速度,直至点火概率不低于50%。

图3为炸药典型的应力—应变曲线,炸药没有屈服时是线弹性的,可以采用Hooke定律描述,超过屈服强度至失效前为硬化段,然后是软化段。以不同应变率加载时炸药的力学行为具有明显的差异。因此采用Visco-SCRAM模型描述炸药力学行为,模型由黏弹性模型和统计裂纹模型两部分组成。黏弹性部分可以描述炸药弹性段和硬化段的力学行为以及应变率效应,统计裂纹部分可以描述炸药的软化行为。

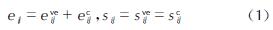

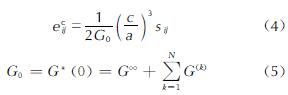

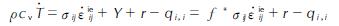

Visco-SCRAM模型[15]由Maxwell黏弹性模型和Dienes[13]的统计裂纹(SCRAM)模型两部分组成,且两者为串联关系。因此,总偏应变是黏弹性偏应变eveij和损伤偏应变ecij两部分之和,而总偏应力与两部分偏应力相等,即:

广义Maxwell黏弹性模型给出黏弹性偏应变与偏应力的关系为:

式中:G(k)和τ(k)分别为第k个Maxwell体的剪切模量和松弛时间; G∞为松弛时间无穷大时的剪切模量。在各向同性条件下,SCRAM模型的损伤偏应变[14]为:

式中:c为裂纹平均半径; a是c的归一化参数,使得c/a为无量纲参数。式(1)~(5)构成了Visco-SCRAM模型的应力应变关系,确定c的表达式后就可以求解Visco-SCRAM模型。

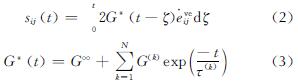

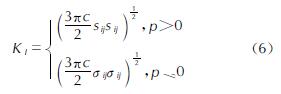

裂纹的扩展是由裂纹尖端附近的应力场驱动的。断裂力学理论[19]定义的应力强度因子可以反映裂纹附近的应力状态。在三维应力状态下,“I”型裂纹即张开型裂纹的有效应力强度因子KI的定义为:

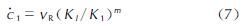

裂纹扩展速度c·可以表达为应力强度因子的函数。在低应力条件下,裂纹能够以较低的速度稳定扩展,裂纹扩展速度与应力强度因子近似呈幂函数关系[20]:

式中:vR为Rayleigh波速。当应力较高时,裂纹失稳并高速扩展,扩展速度可以写为[19]:

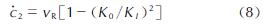

式中:K0为断裂韧性。Dienes[21]将式(7)和式(8)结合起来描述裂纹扩展速度。两者光滑过渡,故在交点处裂纹扩展速度和一阶导数相等。对其求解,可得K1的表达式以及 相交时的应力强度因子K'为:

相交时的应力强度因子K'为:

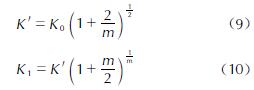

Hackett和Bennett[22]进一步考虑了摩擦对裂纹扩展的影响,则式(9)中的K0需要用K0μ来替换。K0μ的表达式为:

式中:μs为炸药的静摩擦系数。

在连续介质力学[23]框架下,导热微分方程的表达式为:

(12)

(12)

式中:cv为比热; r为热源项; qi,i为热流矢量,对于各向同性材料,傅里叶定律给出,qi,i=-kTi,i,k为导热系数; εieij为非弹性应变; Y≈-(0.05~0.10)σijε·ieij[24],这部分能量对材料自身温升没有贡献,而是用来改变自身微观结构,在受热的条件下能够重新释放出来,类似于潜热; 故f*≈0.90~0.95,f*一般设为常数,这里与Hackett等[22]相同取0.95。

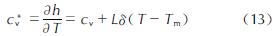

基体炸药的熔化采用Bonnett[25]的等效比热法描述,假设熔化发生在一定的温度范围内,并且包含相变潜能的等效比热在该温度范围内快速变化,其形式如下:

式中:c*v为等效比热; h为焓; L为相变潜热; δ为狄拉克三角函数; Tm为熔点。

炸药在外界刺激下的热源项主要为化学反应放热和剪切摩擦生热。导热微分方程主要用来计算炸药点火前的热传导行为,在此期间化学反应消耗的炸药量几乎可以忽略,故采用简单的Arrhenius反应速率方程就可以描述炸药的反应动力学过程。则化学反应对应的热源项表达式为:

rreact=ρΔHZexp(-Ea/RT)(14)

式中:ΔH为炸药单位质量反应热; Z为指前因子; Ea为活化能; R为普适气体常数。

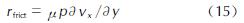

Visco-SCRAM模型认为微观裂纹是炸药发生损伤的原因,每个计算单元中均存在一个微裂纹,故裂纹面即为最大应变率所在平面。此外,在Visco-SCRAM模型中,剪切摩擦是炸药点火的控制机理,则剪切摩擦对应的热源项表达式为:

式中:μ为炸药动摩擦系数; 为裂纹面法线方向的速度梯度,即最大偏应变率。

为裂纹面法线方向的速度梯度,即最大偏应变率。

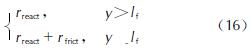

因此,在计算rfrict时,首先需要对偏应变率张量进行特征值问题求解,得到最大偏应变率的特征方向。进一步求解此特征方向上的偏应力,检验其是否大于最大静摩擦力,若大于则放热,否则不放热。若裂纹尺寸为lf,则总热源项的表达式为:

至此,可以通过Visco-SCRAM模型判断炸药在过载环境下是否会点火以及点火位置。

以二次开发的方法将Visco-SCRAM模型嵌入LS-DYNA,并进行过载环境下的模拟。单位制cm-g-μs,装置主要部分均为回转体,因此为节省计算时间采用二维轴对称模型对装置进行建模。计算模型和各部分尺寸见图4。

计算模型对装置进行了简化,主要包含重锤、上下冲头、侧向约束和试件系统。重锤、上下冲头、侧向约束的材质均为钢,其中上下冲头材质为高强度合金钢。试件系统由待测炸药、钢缓冲垫、聚乙烯缓冲垫和聚乙烯侧向约束组成。

计算时,重锤以某个初始速度撞击上冲头,随后应力波在上下冲头和试件中来回传播。由于下冲头与支撑系统连接,下冲头底部没有轴向位移。因此在初始阶段炸药的应力逐渐增加,重锤速度逐渐减小。当重锤速度为零时,炸药开始卸载,应力逐渐减小直至完全卸载。整个过程中,只有试件系统变形较大。由于侧向钢约束的存在,试件的变形主要是轴向变形。在试验的打击速度范围内,试件的轴向变形不超过30%。因此,整个计算模型采用Lagrange算法进行求解。

在确定了计算模型和算法后,还需要确定各部分的材料模型和状态方程。重锤、上下冲头、侧向约束在整个过程中变形较小,故均采用线弹性模型。试件中的压力高、变形大,故试件中的钢和聚乙烯均采用含有状态方程的材料模型。DNAN基熔注炸药(RBHL-1)的Visco-SCRAM模型参数见表2。

参数1~24:BLK(体积模量)、GINF(弹性弹簧剪切模量)、Gi(第i个Maxwell单元的剪切模量)、TAUi(第i个Maxwell单元的松弛时间)等力学参量均由SHPB试验和准静态力学试验标定得到,并将XNUM(Maxwell单元数量)设为9; RBHL-1的基体炸药为DNAN,DNAN熔化相关参数为T1(相变初始温度)、T2(相变终止温度)、QPT(M)(单位质量的相变潜热),上述参数的选取

参考文献[26]。

参数25~29:A为c/a中的无量纲裂纹参数a,XM为平均裂纹增长速率中的指数m,VMAX为裂纹最大扩展速度vmax,XK0为材料断裂韧性,CRKSIZ初始平均裂纹半径,上述参数较难通过试验获得,均与Bennett[15]一致。

参数30~31:Hackett[22]静摩擦系数取0.5,XMU(动摩擦系数)一般比静摩擦系数小,此处取0.35; CONVER(非弹性功转换为热的转换百分比)取0.95。

参数32~37:通过排水法测得RBHL-1炸药RHO(初始密度)1.76g/cm3; T0(初始温度)300K; K(导热系数)和CV(比热容)由LFA-447激光法导热分析仪测量; TSTR(活化温度)即活化能Ea与普适气体常数R的商,QA(V)为单位体积反应热与指前因子的乘积,热分解特性由DSC-204 HP差示扫描量热仪测量,采用Kissinger法得到活化能为150kJ/mol,指前因子为3.42×1021s-1,反应热为430J/g。

采用以上模型对炸药进行了模拟计算,图5和图6为重锤速度v=9m/s时的典型计算结果。试件中缓冲垫和炸药从上到下按照钢缓冲垫-PE缓冲垫-炸药-PE缓冲垫顺序排列。由于钢的强度高于聚乙烯,在重锤打击作用下钢的轴向变形量较小。因此,尽管在钢缓冲垫和炸药之间有4mm的聚乙烯作为缓冲,但是炸药的上表面仍然损伤较严重,见图5(c),而且裂纹尺寸扩展较快,见图6(b)。对比图5(b)和图5(c)可以发现:炸药损伤越严重的地方,热点温度越高。在相同的压力和剪切力作用下,裂纹发生剪切摩擦时单位面积的放热量相同。随着裂纹尺寸的增加,裂纹摩擦产生的热量也有所增加,导致热点温度较高。因此,在损伤程度更加严重的上表面,热点温度也更高。此外,热点温度还和热传导有关,裂纹摩擦放出的热量会通过热传导的方式逐渐均布到裂纹四周。图6(a)和图6(b)中,B点裂纹尺寸略大于C点,所以在开始阶段B点温度也略高于C点。由于热传导的影响,700μs以后,B点温度与C点趋于一致。

在计算炸药阈值速度时,采用“升降法”调整重锤速度。从8m/s开始,以0.5m/s为步长逐渐增加重锤速度,炸药点火时T·→∞,据此判断炸药是否点火。在不同的重锤速度下炸药A点(即热点温度最高点)的温度历史见图7。

由图7可知,重锤速度v≤9.0m/s时炸药均未发生点火。而重锤速度提升到9.5m/s时,在t=707.6μs炸药在A点处点火(见图8),随后以A点为起爆点形成爆轰波向四周传播。因此,计算得到的DNAN基熔注炸药(RBHL-1)的速度阈值为9.0~9.5m/s。

以炸药50%概率发生点火的加载速度为阈值速度,试验结果表明RBHL-1炸药以8.97m/s速度加载时,10发试验炸药都不点火; 以9.26m/s速度加载时,10发试验有5发点火,因此RBHL-1炸药发生点火的速度阈值为9.26m/s。图9给出了RBHL-1炸药试验前后的试件状态,图9(b)中重锤以8.97m/s的速度加载,药柱在压缩和剪切作用下发生较大变形,但未发生反应; 重锤以9.26m/s加载时,图9(c)中炸药药柱完整,药柱上表面、钢缓冲垫和上PE缓冲垫均有炭黑生成,但是药柱底部颜色无明显变化,说明仅在药柱上表面发生了微弱反应。图9(d)中炸药反应剧烈,大部分炸药在反应过程中消耗,上PE缓冲垫完全变黑,炭黑积聚量较大。这些试验结果均证明炸药的点火位置位于炸药药柱上表面。

点火后形成的燃烧波或爆轰波在向底部传播过程中可能会熄灭,如图9(d)所示药柱还剩余部分未反应炸药,下PE缓冲垫炭黑积聚量明显低于上PE缓冲垫。

数值模拟计算与试验结果均证明炸药的点火位置位于炸药药柱上表面,且计算得到的速度阈值9.0~9.5m/s与试验结果9.26m/s相符,计算结果与试验结果一致性良好,证明剪切摩擦是抗过载性能评估试验中炸药的点火机制。

(1)建立了炸药抗过载性能评估装置的数值模型,以二次开发的方法将Visco-SCRAM模型嵌入LS-DYNA,通过LS-DYNA对DNAN基熔注炸药(RBHL-1)在过载条件下的响应过程进行了计算。数值模拟结果表明,在重锤打击过程中,药柱上表面的损伤最为严重。损伤越严重的地方,热点温度越高。

(2)抗过载性能评估试验验证了计算阈值速度的准确性和模型的可行性,说明剪切摩擦是炸药装药在过载条件下的点火机制。对于以剪切摩擦为点火机制的工况,Visco-SCRAM模型计算结果与试验结果吻合较好。提高炸药装药质量和炸药中对含能材料的保护能力是提高炸药抗过载性能的重要手段。